XE210C Hydraulic Excavator

Operating and Maintenance Manual

120

h)

Hang “No Operation” nameplate to the control lever.

i)

Pull the safety locking rod to LOCK (lock).

j)

Check the hydraulic system for leaks.

Replacement of fuel filter

a)

Replace the fuel filter every 250 hours.

b)

For the sake of safety and environmental protection, use the proper

containers always for draining the fuel oil. Don’t pour the fuel on the

ground, into the ditch, river, pond or lake, and treat the waste fuel

properly.

c)

Remove the cartridge filter with a filter spanner.

d)

Apply a thin layer of clean fuel to the gasket of new cartridge filter.

e)

Tighten the cartridge filter by hands until the gasket contacts the seal face.

f)

Turn the cartridge filter by ca. 2/3 circle with a filter spanner to tighten it, but it shall not be screwed

too tight.

g)

After replacing the cartridge filter, bleed the air out of hydraulic system.

The above methods are for the replacement of second-class fuel filter on the engine side, and those of

first-class fuel filter on the pump chamber side are the same as the above methods.

Cleaning of outer element of air filter

Clean the outer element of air filter every 250

hours or when the warning lamp of air filter

element brightens, clean the outer element of

air filter.

Replacement of inner and outer elements of

air filter

After six-time cleanings or one year, replace inner and

outer elements of air filter.

a)

Park the machine on flat ground.

b)

Stop the engine as per the shutdown steps of engine (P20).

Important:

if the shutdown steps of engine are incorrect, the turbo supercharger

may be damaged.

c)

Pull the safety locking rod to LOCK (lock).

d)

Loosen the fixing clip, and remove the end cover.

e)

Remove the outer filter element.

f)

Flap outer filter element lightly by hands, and don’t on any hard

object.

g)

In case of cleaning outer filter element with compressed air, blow

outward from inner side of outer filter element.

Note: adopt low-pressure air (less than 0.2MPa) to

clean, have the personnel in the adjacent area away,

protect against the splashed fragments, and wear the

personal protection equipment, including safety goggles

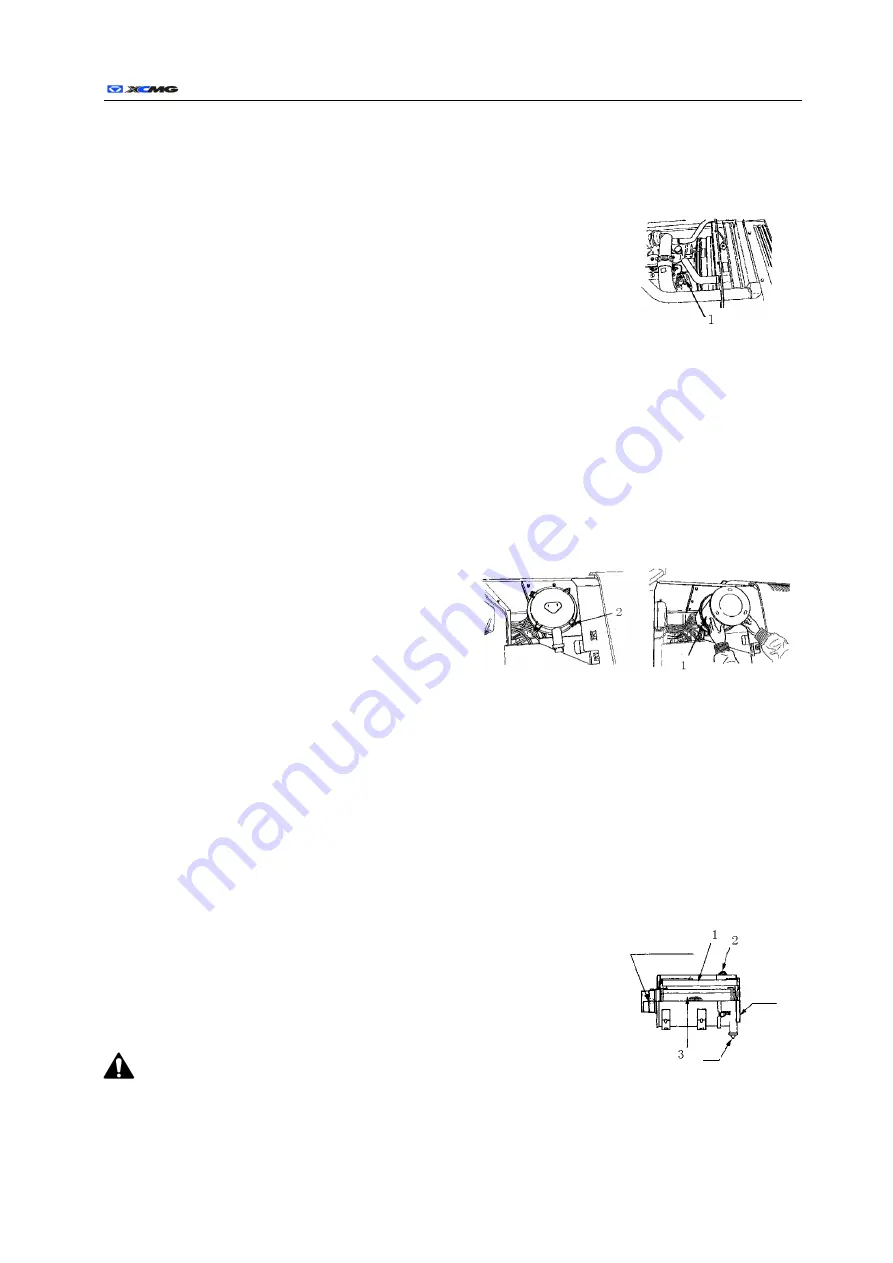

Fig.2-40

1

-

Outer filter element

2

-

Fixing clip

3

-

Inner filter element

Fig.2-39

1

-

Outer filter element 2

-

Fixing clip

Fig.2-38

1

-

Cartridge filter

Air clogging switch

Shield

cover

Valve