9

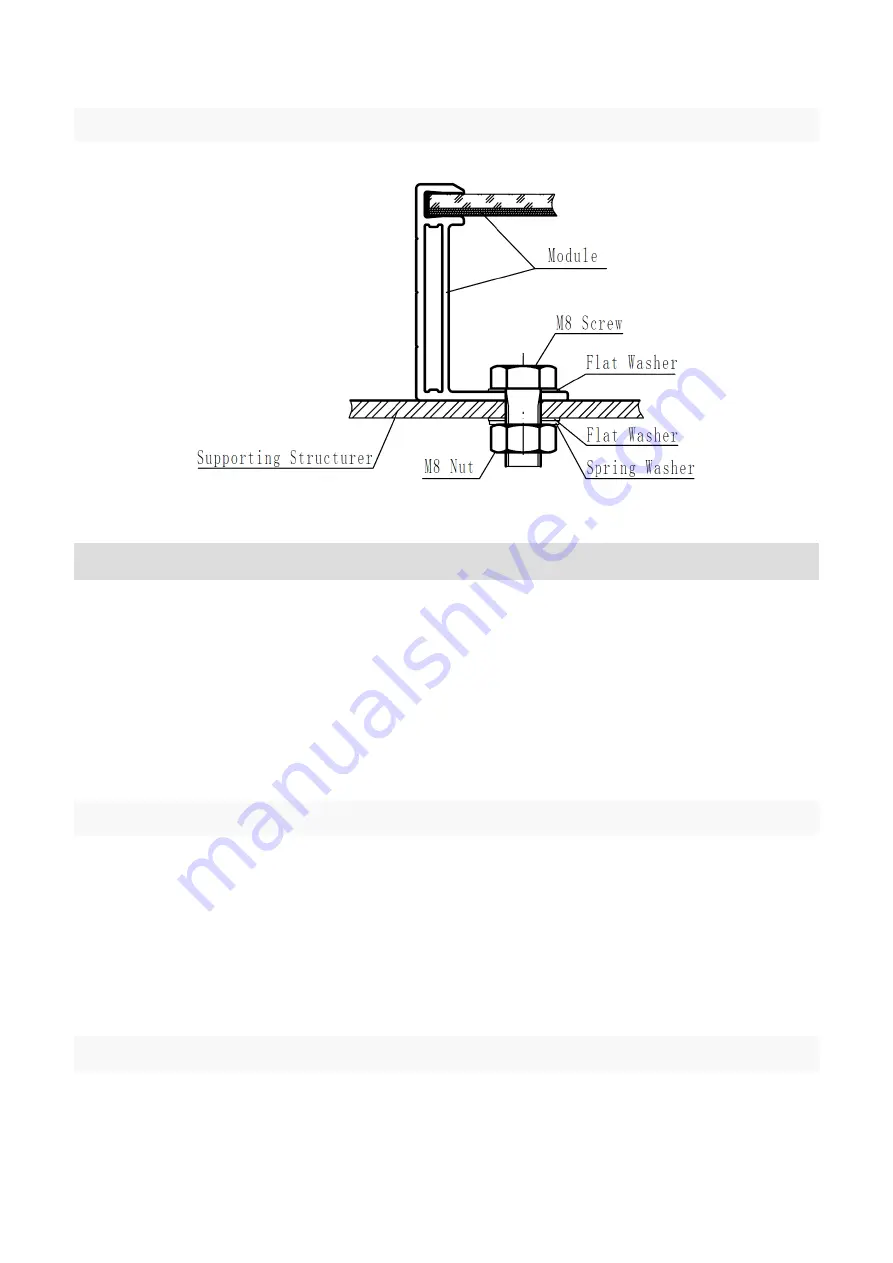

MOUNTING WITH SCREWS

In case of mounting modules directly to the construction XDISC S.A. advises to use M8 screws.

MAINTENANCE OF PHOTOVOLTAIC MODULES ASOL-250P-WSR

Photovoltaic modules require very little maintenance with respect to their configuration, except for parts and

the interior circuits of the cells and the connection welding insulated by layers of protective material.

Maintenance covers the following processes:

-

Periodic cleaning of the module.

-

Visual inspection of possible internal deterioration of the water-tightness of the module.

-

Control of the state of the electrical connections and wiring.

-

Eventually, control of the electrical characteristics of the module.

PERIODIC CLEANING OF THE MODULE

The dirt accumulated on the transparent cover of the module reduces its performance and can produce

reverse effects similar to those produced by shading. The problem can become serious in the case of industrial

waste or waste caused by birds. The intensity of the effects depends on the opaqueness of the residue. The

layers of dust that reduce the intensity of the sun are not dangerous and the reduction in power is not usually

very significant. The regular recurrence of the cleaning process depends, logically, on the intensity of the

process. Rainfall can help in many cases to reduce or eliminate the need to clean the modules.

The cleaning in general should be done by the special trained staff, always trying to avoid the accumulation of

the water on the module. It is not advisable to use pressure hoses under any circumstances.

VISUAL INSPECTION

The visual inspection is meant to detect possible failures, specifically:

-

Possible breaks in the glass.