Xerox Document Centre Reference Guide

Page 13 - 3

1

3. Pa

per &

Sto

ck

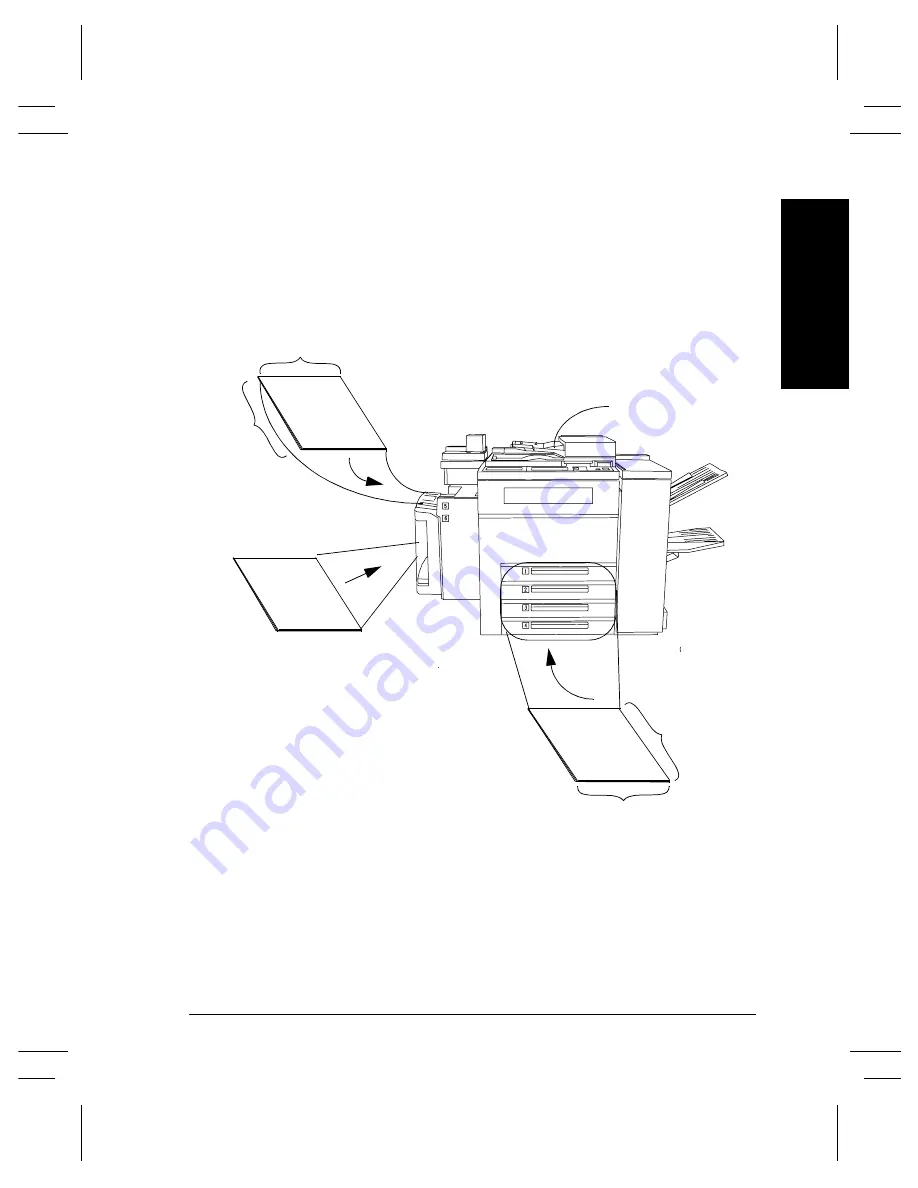

Paper Tray Media Capability

The illustration below outlines the capabilities of the individual

paper trays and their ability to process a variety of paper sizes.

Trays 1-4

8 to 17 in. or 203 to 432 mm

Tray 5

Bypass

Tray

4 t

o

12

i

n

.

o

r

1

02

to

30

5 mm

5.83 to 18 in. or

148 to 457 mm

Tray 6

Only

8.5 x 11 inch or A4

LEF

5

.25

to 1

2

in.

or

1

33

to

30

5 mm

Call the Welcome Center to set Trays

1, 2, 3, or 4 to process 12 x 18 inch

stock permanently.

Document Feeder

Refer to Table 6 for more information

Summary of Contents for 255 DC

Page 2: ......

Page 20: ...x Xerox Document Centre Reference Guide ...

Page 84: ...Page 4 36 Xerox Document Centre Reference Guide Notes ...

Page 100: ...Page 5 16 Xerox Document Centre Reference Guide Notes ...

Page 112: ...Page 6 12 Xerox Document Centre Reference Guide ...

Page 182: ...Page 9 56 Xerox Document Centre Reference Guide Notes ...

Page 213: ...Xerox Document Centre Reference Guide Page 10 31 10 Tracking Usage System Tools Notes ...

Page 214: ...Page 10 32 Xerox Document Centre Reference Guide ...

Page 225: ...Xerox Document Centre Reference Guide Page 11 11 11 Sixth Sense System Tools Notes ...

Page 226: ...Page 11 12 Xerox Document Centre Reference Guide ...

Page 260: ...Page 12 34 Xerox Document Centre Reference Guide ...

Page 276: ...Page 13 16 Xerox Document Centre Reference Guide Notes ...

Page 288: ...Page 14 12 Xerox Document Centre Reference Guide Notes ...

Page 304: ...Page 15 16 Xerox Document Centre Reference Guide ...

Page 310: ...Page 16 6 Xerox Document Centre Reference Guide ...

Page 321: ......