October 2012

1-8

ColorQube 8570/8870 Service Manual

Routine Maintenance Activities, Cleaning Procedures

Revised, 3rd Revision - Xerox Internal Use Only

Service Call Procedures

Lubrication

The printer is lubricated during assembly at the factory and does not require periodic lubrica-

tion. Some parts require lubrication following replacement. These parts are identified in the

replacement procedures. When lubricating during replacement, use the grease approved for

all Phaser printers.

CAUTION

Plastic parts will deteriorate when unspecified grease and chemicals are used. To avoid dam-

age to the printer, use only Rheolube 768 grease.

•

Rheolube 768 Grease: Part Number 070E00890

Cleaning Procedures

Purpose

The purpose is to provide cleaning procedures to be performed at every call.

Cleaning is indicated if the printer is having print-quality or paper-feeding problems. Some

cleaning procedures, such as purging the jet nozzles are done automatically when necessary.

Other procedures, such as scrubbing the Paper Feed Rollers with a moistened lint-free wipe,

must be done by the customers, but only if the Rollers are visibly dirty.

Cleaning is indicated by any of the following:

•

Light stripes or missing colors appear in prints.

•

Ink smears or random streaks appear on the front or back of prints.

•

Only spots appear along the tops of prints.

•

Mispicks or multiple picks occur at the media tray.

•

Persistent paper jams inside the printer or at the media tray if the Rollers are visibly dirty.

•

Wiggly vertical stripes caused by too much oil created by a dirty Drum Maintenance Unit

blade.

•

Most print-quality problems can be corrected by running the cleaning procedures on the

printer’s Control Panel menu.

Procedure

CAUTION

Do not use any solvents unless directed to do so in this manual.

General Cleaning

Use a dry lint-free cloth or a lint-free cloth moistened with water for all cleaning unless directed

otherwise in this manual. Wipe with a dry, lint-free cloth if a moistened cloth is used.

Inspect the vents on the exterior of the printer for dust. Clean as necessary.

Appropriate cleaning procedures, as listed in

Table 1

and

Table 2

, should be performed when

specific print-quality or paper transport problems occur.

NOTE: Clear packaging tape (such as 3M 3750) is recommended for cleaning the Pick Roller

and Separator Pad.

1.

Feed Components (Rolls and Pads)

Follow the General Cleaning procedure in

Table 1

and

Table 2

.

2.

Jam Sensors

Clean the Sensors with a dry cotton swab.

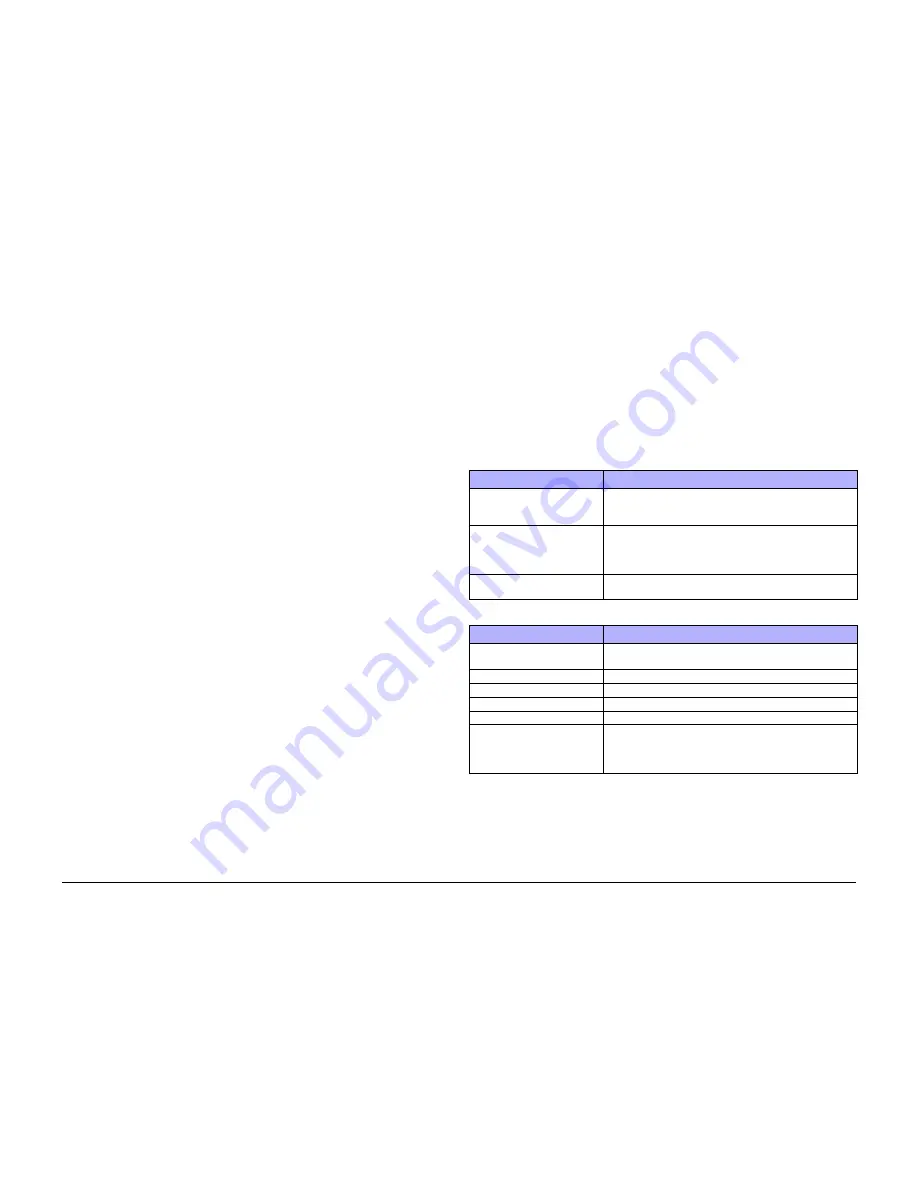

Table 1 Light Stripes or Missing Colors

Problem Type

Solution

Missing or light-colored stripes

on prints.

From the Control Panel menu, select Troubleshooting ->

Print Quality Problems -> Eliminate Light Stripes -> Start

Basic Clean Cycle.

Ink smears on the front, back,

or edges of a page.

From the Control Panel menu, select Troubleshooting ->

Print Quality Problems -> Remove Print Smears.

Check the Drum Maintenance Unit for ink and paper-dust

build-up on the Blade.

Oil (Drum fluid) on top edge of

print.

From the Control Panel menu, select Troubleshooting ->

Print Quality Problems -> Remove Print Smears.

Table 2 Media Jams

Problem Type

Solution

Tray 1 (MPT) jams.

Clean the Pick Roller. Refer to the

Clean the Tray 1 Pick

Roller

procedure.

Front Door jams.

Clean the Transport Rollers.

Exit jams.

Clean the Exit Rollers and Stripper Blade.

Tray 2-5 jams.

Clean the appropriate Tray Feed Roller.

Duplex path jam.

Clean the Preheater, Duplex Rollers, and Exit Rollers.

Double picks.

Clean the Pick Rollers and Separator Pad using a moistened

lint-free cloth.

Clean the pick pad with clear packaging tape (refer to Clean-

ing the Pick Roller procedure).

Summary of Contents for COLORQUBE 8570

Page 1: ...ColorQube 8570 8870 Printer ColorQube 8570 8870 Service Manual Xerox Internal Use Only...

Page 2: ......

Page 423: ......