October 2012

8-21

ColorQube 8570/8870 Service Manual

Print Process

Theory of Operation

Xerox Internal Use Only - Revised, 3rd Revision

Printing

To print, the Drum starts rotating at a speed dependent upon print resolution. As the Drum

reaches the correct speed, the jets begin to fire to deposit the image on the oiled portion of the

Drum. As the jets fire, the Printhead moves from right to left to complete the image on the

Drum.

When printing, the printer performs a “six-jet interlace,” in which each jet lays down a particular

number of pixel columns, depending on the print resolution. Each jet lays down one pixel col-

umn for each Drum rotation, which varies from 6 to 16 rotations, depending on the print resolu-

tion. Interlacing “averages out” the variability between jets by interlacing each jet with other

jets. In some test prints, the Printhead moves to the right and lays down 309 parallel bands of

ink. Each band is composed of 15 pixel columns of dots from an individual jet.

Jet substitution allows a better performing jet to be used in place of a missing or poorly per-

forming neighboring jet. When jet substitution is used, the Printhead makes a second right-to-

left movement to deposit the pixel columns of the substituted jets. See

Jet Substitution Mode

in

Chapter 3 - Image Quality.

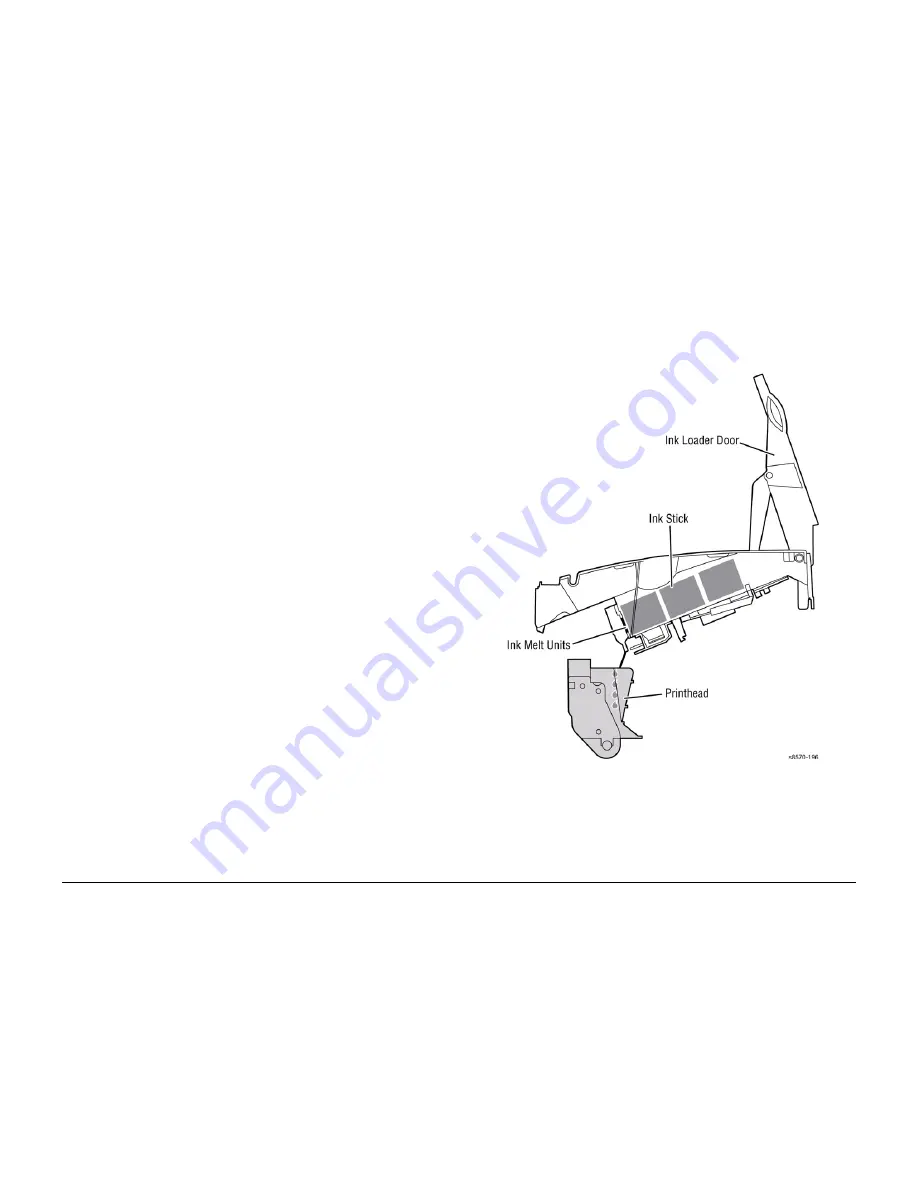

Ink Loader

The Ink Loader consists of four parallel channels with an ink melting element at the end of each

channel. Ink sticks, one color loaded in each channel, are pressed by coil spring pressure into

the melting elements. As ink is required by the Printhead, the appropriate color’s melting ele-

ment is activated and the end of the ink stick is melted. The melted ink drips into the ink reser-

voirs of the Printhead underneath.

Figure 2 Ink Loading

Summary of Contents for COLORQUBE 8570

Page 1: ...ColorQube 8570 8870 Printer ColorQube 8570 8870 Service Manual Xerox Internal Use Only...

Page 2: ......

Page 423: ......