6/02

4-168

DC1632/2240

ADJ 9.6

Prelaunch Training/Review

Repairs and Adjustments

ADJ 9.6 Color Registration (dC685)

Purpose

To establish correct horizontal and vertical positioning of the four primary color images

The procedure consists of the following steps, which must be performed in the listed sequence:

1.

Belt Edge Learn

- to align the Transfer Belt positioning system.

2.

Fine Skew Setup

- automatically performs horizontal and vertical alignment, and reports

any skew in the various images caused by ROS misalignment. This skew must be cor-

rected through manual adjustment

3.

IN/OUT Setup

- automatically performs magnification adjustment so that scan lines are

the same length for all four colors. Also checks for skew.

4.

Center Setup

- Aligns the midpoints of scan lines for all colors, for magnification balance.

There is also a

Rough Skew Setup

for cases where the skew is outside the measurement

parameters of the Fine Skew test.

This procedure is required if any of the following occur:

ï

ROS removal

ï

NVM Initialization

ï

An Image Quality RAP directed performance of this procedure.

Check

NOTE: Excessive toner on the Transfer Belt will prevent completion of the adjustment. Make

sure that there are no Image Quality problems, and that the IBT Cleaner is functioning cor-

rectly. Resolve any Image Quality problems before attempting this adjustment.

1.

Open the Front door and cheat the interlock.

2.

Connect the PWS to the machine and enter Diagnostic Mode (refer to

Entering Diagnostic

Mode using the PWS

).

3.

Under the

Adjustments

tab, select

RegiCon

.

Set the Belt Edge Alignment

1.

Select the

Belt Edge Learn Mode

tab.

2.

Select the

Edge Learn Mode

button.

3.

Select

Start

.

4.

If Edge Learn fails, check:

ï

Installation of IBT Belt Assembly (

REP 9.15

).

ï

Installation of IBT Edge Sensor (

PL 5.4

).

ï

Installation of IBT Home Sensor (

PL 5.4

).

Perform Edge Learn again. If it fails, replace the IBT Edge Sensor (

PL 5.4

).

If it fails again, replace IBT Home Sensor (

PL 5.4

).

5.

When Edge Learn is successful, select the

RegiCon Setup Cycle (dC685)

tab.

Check the Fine Skew Setup

1.

Select the

Skew (Fine) Setup

button.

2.

Select

Start

.

3.

Check the

Judgement

window. If NG is displayed, perform the Rough Skew Setup then

repeat the Fine Skew check.

4.

If

OK

is displayed in the

Judgement

window, check the

Skew Correction

row in the

Skew Values

window. If a value greater than 1 is displayed for any color, perform the

Adjustment, then perform the IN/OUT Setup check.

Check the IN/OUT Setup

1.

Select the

IN/OUT Setup

button.

2.

Select

Start

3.

Check the

Judgement

window. If NG is displayed, perform the Adjustment, then perform

the Center Registration check

4.

If IN/OUT Setup is

OK

, check the Center Registration.

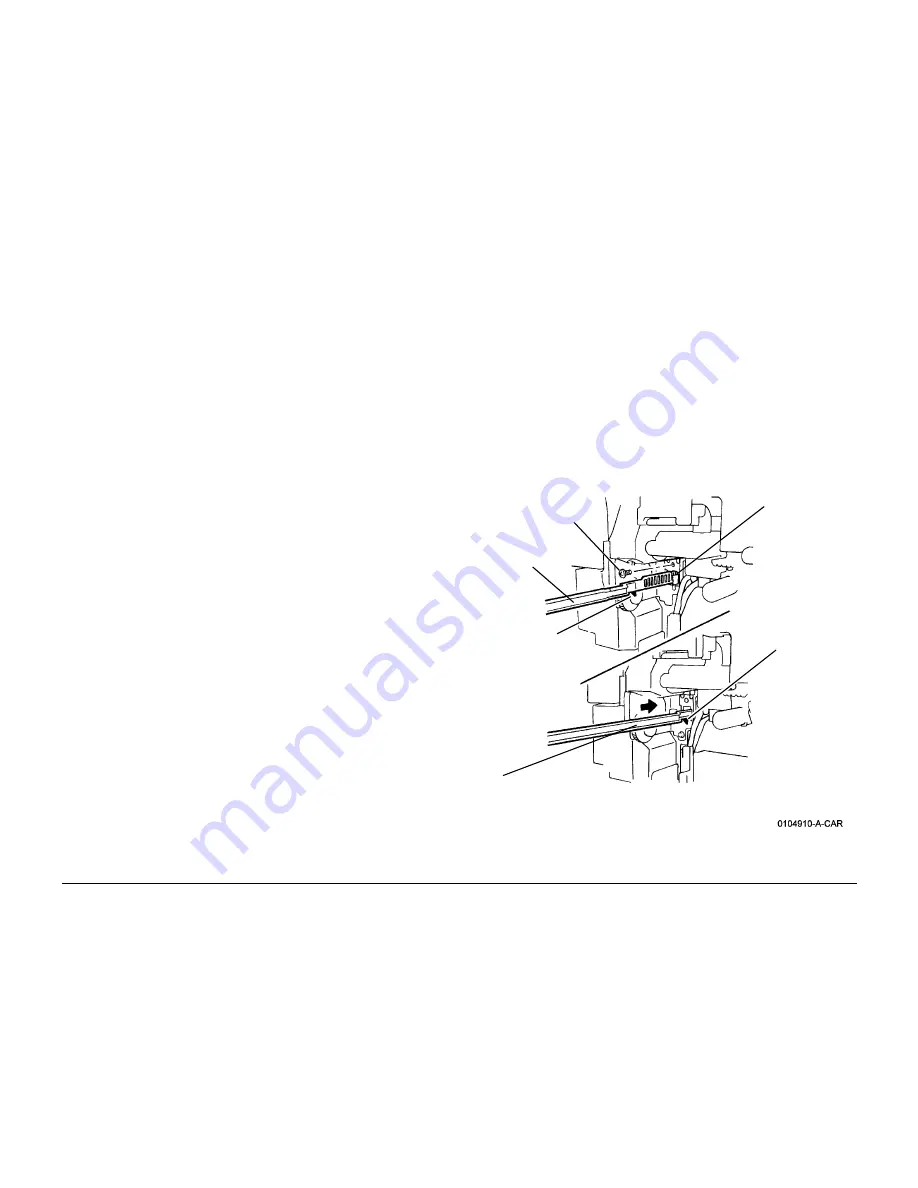

Check the Center Registration

1.

Remove the Waste Toner Cartridge.

2.

Move MOB sensor to the center position (

Figure 1

).

Figure 1 Moving MOB Sensor to Center Position

3.

Reinstall the Waste Toner Cartridge.

1

Remove

Screw

2

Remove

Cleaning

Tool from

Front Cover

3

Pull out MOB

Sensor slightly

with needle nose

pliers (pliers not

shown).

Hook end of

Cleaning Tool to

MOB Sensor.

4

Push in MOB Sensor until sensor stops.

Tool will be positioned as shown (Stop Tab

on tool should be flush with frame).

5

Remove Tool

NOTE:

Stop Tab

NOTE:

Stop Tab

Summary of Contents for DocuColor 1632

Page 4: ...6 02 2 DC1632 2240 Prelaunch Training Review Introduction ...

Page 9: ...6 02 vii DC1632 2240 Introduction Prelaunch Training Review Translated Warnings ...

Page 22: ...6 02 xx DC1632 2240 Prelaunch Training Review Introduction ...

Page 24: ...6 02 1 2 DC1632 2240 Prelaunch Training Review Service Call Procedures ...

Page 38: ...6 02 2 8 DC1632 2240 Prelaunch Training Review Status Indicator RAPs ...

Page 44: ...6 02 2 14 DC1632 2240 1 306 Prelaunch Training Review Status Indicator RAPs ...

Page 452: ...6 02 3 2 DC1632 2240 Prelaunch Training Review Image Quality ...

Page 474: ...6 02 3 24 DC1632 2240 Image Quality Specifications Prelaunch Training Review Image Quality ...

Page 486: ...6 02 4 12 DC1632 2240 REP 1 13 Prelaunch Training Review Repairs and Adjustments ...

Page 490: ...6 02 4 16 DC1632 2240 REP 4 4 Prelaunch Training Review Repairs and Adjustments ...

Page 514: ...6 02 4 40 DC1632 2240 REP 5 19 Prelaunch Training Review Repairs and Adjustments ...

Page 568: ...6 02 4 94 DC1632 2240 REP 9 27 Prelaunch Training Review Repairs and Adjustments ...

Page 572: ...6 02 4 98 DC1632 2240 REP 10 3 Prelaunch Training Review Repairs and Adjustments ...

Page 616: ...6 02 4 142 DC1632 2240 REP 12 20 Prelaunch Training Review Repairs and Adjustments ...

Page 624: ...6 02 4 150 DC1632 2240 REP 14 11 REP 14 12 Prelaunch Training Review Repairs and Adjustments ...

Page 638: ...6 02 4 164 DC1632 2240 ADJ 6 1 Prelaunch Training Review Repairs and Adjustments ...

Page 660: ...6 02 4 186 DC1632 2240 ADJ 12 1 Prelaunch Training Review Repairs and Adjustments ...

Page 766: ...6 02 6 2 DC1632 2240 Prelaunch Training Review General Procedures and Information ...

Page 864: ...6 02 7 2 DC1632 2240 Prelaunch Training Review Wiring Data ...

Page 904: ...6 02 7 42 DC1632 2240 Plug Jack Locations Prelaunch Training Review Wiring Data ...

Page 906: ...6 02 7 44 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 2 ACN Wirenet ...

Page 907: ...6 02 7 45 DC1632 2240 Wirenets Wiring Data Prelaunch Training Review Figure 3 3 3VDC Wirenet ...

Page 917: ...6 02 7 55 DC1632 2240 Wirenets Wiring Data Prelaunch Training Review Figure 13 24VDC 1 of 4 ...

Page 918: ...6 02 7 56 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 14 24VDC 2 of 4 ...

Page 919: ...6 02 7 57 DC1632 2240 Wirenets Wiring Data Prelaunch Training Review Figure 15 24VDC 3 of 4 ...

Page 920: ...6 02 7 58 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 16 24VDC 4 of 4 ...

Page 921: ...6 02 7 59 DC1632 2240 Wirenets Wiring Data Prelaunch Training Review Figure 17 24V RTN 1 of 4 ...

Page 922: ...6 02 7 60 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 18 24V RTN 2 of 4 ...

Page 926: ...6 02 7 64 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 22 IIT 24V RTN ...

Page 928: ...6 02 7 66 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 24 DADF 5V RTN ...

Page 936: ...6 02 7 74 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data ...

Page 939: ...6 02 7 77 DC1632 2240 Chain 01 Wiring Data Prelaunch Training Review Figure 3 LVPS Control ...

Page 946: ...6 02 7 84 DC1632 2240 Chain 01 Prelaunch Training Review Wiring Data Figure 10 Monitoring ...

Page 948: ...6 02 7 86 DC1632 2240 Chain 02 Prelaunch Training Review Wiring Data Figure 2 LCD Control ...

Page 955: ...6 02 7 93 DC1632 2240 Chain 03 Wiring Data Prelaunch Training Review Figure 7 PWS Interface ...

Page 956: ...6 02 7 94 DC1632 2240 Chain 03 Prelaunch Training Review Wiring Data Figure 8 Billing ...

Page 957: ...6 02 7 95 DC1632 2240 Chain 03 Wiring Data Prelaunch Training Review Figure 9 Monitoring ...

Page 969: ...6 02 7 107 DC1632 2240 Chain 06 Wiring Data Prelaunch Training Review Figure 2 Image Input ...

Page 1001: ...6 02 7 139 DC1632 2240 Chain 08 Wiring Data Prelaunch Training Review Figure 5 Registration ...

Page 1002: ...6 02 7 140 DC1632 2240 Chain 08 Prelaunch Training Review Wiring Data Figure 6 Monitoring ...

Page 1012: ...6 02 7 150 DC1632 2240 Chain 09 Prelaunch Training Review Wiring Data Figure 10 Development Y ...

Page 1013: ...6 02 7 151 DC1632 2240 Chain 09 Wiring Data Prelaunch Training Review Figure 11 Development M ...

Page 1014: ...6 02 7 152 DC1632 2240 Chain 09 Prelaunch Training Review Wiring Data Figure 12 Development C ...

Page 1029: ...6 02 7 167 DC1632 2240 Chain 09 Wiring Data Prelaunch Training Review Figure 27 Stripping ...

Page 1032: ...6 02 7 170 DC1632 2240 Chain 09 Prelaunch Training Review Wiring Data Figure 30 IBT Cleaning ...

Page 1042: ...6 02 7 180 DC1632 2240 Chain 10 Prelaunch Training Review Wiring Data Figure 3 Fusing ...

Page 1046: ...6 02 7 184 DC1632 2240 Chain 10 Prelaunch Training Review Wiring Data Figure 7 Duplex Drive ...

Page 1047: ...6 02 7 185 DC1632 2240 Chain 10 Wiring Data Prelaunch Training Review Figure 8 Monitoring ...

Page 1055: ...6 02 7 193 DC1632 2240 Chain 12 Wiring Data Prelaunch Training Review Figure 8 Staple Control ...

Page 1056: ...6 02 7 194 DC1632 2240 Chain 12 Prelaunch Training Review Wiring Data Figure 9 Set Eject ...