6/02

4-170

DC1632/2240

ADJ 9.7, ADJ 9.8

Prelaunch Training/Review

Repairs and Adjustments

ADJ 9.7 IIT Calibration (dC945)

Purpose

ï

To calculate and set up the White Reference Correction Coefficient.

ï

To correct the IIT sensitivity dispersion (CCD Calibration).

ï

Adjust the light axis correction data when replacing the Lens unit.

Adjustment

1.

Clean the Optics:

a.

Switch off the power and allow the Exposure Lamp to cool off.

b.

Using the optical Cleaning Cloth, clean the front and rear of the Document Glass,

Document Cover, White Reference Strip, Reflector, and Mirror.

c.

Clean the Exposure Lamp with a clean cloth and Film Remover.

d.

Clean the Lens with Lens and Mirror Cleaner and lint free cloth.

2.

Connect the PWS to the machine and enter Diagnostic Mode (refer to

Entering Diagnostic

Mode using the PWS

).

3.

Under the

Adjustments

tab, select

Max Setup

.

4.

Select the

IIT Calibration

tab.

5.

Select the

White Reference Adjustment

button.

6.

Press

Start

.

7.

Follow the instructions on the PWS screen, then select OK.

8.

Select the

Read

button.

9.

The setup values are displayed on the

White Reference Setup Value

screen.

10. When White Reference setup is done, select the CCD Calibration button.

11. Press

Start

.

12. Follow the instructions on the screen, then select OK.

13. The obtained data is displayed in the

b* Calibration Coefficients

window.

14. Select [Close] to return to the Color Image Quality Adjustment screen.

NOTE: Do not select Optical Axis Calibration unless replacing the Lens Kit (

PL 18.4

). Refer to

REP 6.4

.

ADJ 9.8 Hard Disk Diagnostics/Setup (dC355)

Purpose

CAUTION

This procedure does not work as described in the current tool; the spec is being rewritten.

This description is an attempt to document the new spec. DO NOT USE.

To perform the diagnostics in the hard disk and setup (initialization) of each partition.

NOTE: Perform this procedure only after the customer's approval is obtained. Check what

kind of data are stored in each partition according to the list below since some partitions store

fonts etc. that the customer has installed.

NOTE: Setup function is only available from customer's mode or UI-Diag mode in Partition A.

Adjustment

1.

Connect the PWS to the machine and enter Diagnostic Mode (refer to

Entering Diagnostic

Mode using the PWS

).

2.

Under the

Diagnostics

tab, select

System Test

.

3.

Select the

Hard Disk Diag. Program

tab.

4.

Select the appropriate

Partition

(see

Table 1

.)

5.

Select the Diag Type (see

Table 2

).

6.

Press

Start

.

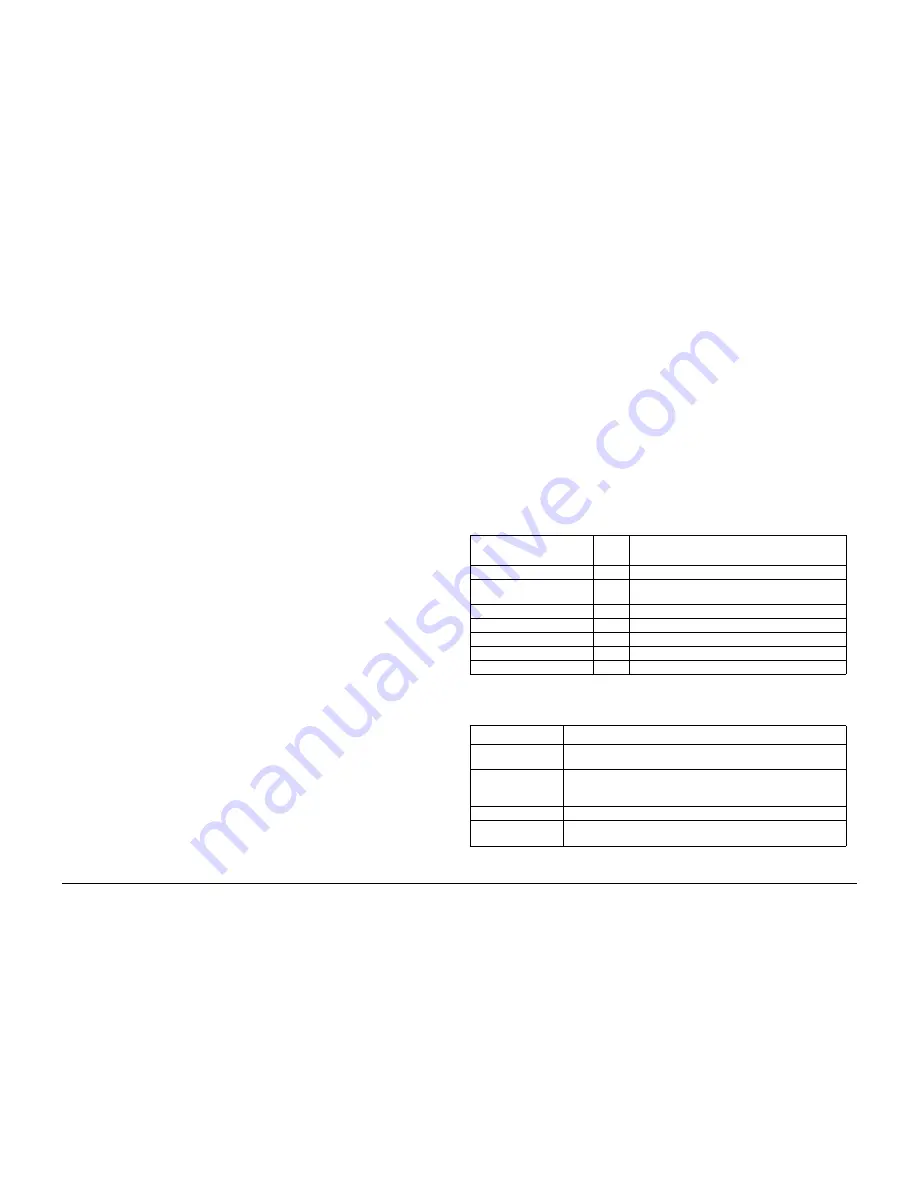

Table 1 Partition Content

Display of appropriate

hard disk column

Size

(GB)

Stored information and usages

MP All

All

All the items in Partition 1~6

MP Partition 1 (a)

2.0

Font, Form/Logo, SMB Folder (Config. txt, driver),

Job Template

MP Partition 2 (b)

2.0

Printing range

MP Partition 3 (c)

1.2

Scan, Report, Mailbox, Security - Print

MP Partition 4 (d)

2.0

PLD, Others

MP Partition 5 (e)

2.0

Copying range

MP Partition 6 (f)

0.5

Spool Cont Control Information, Log

Table 2

Work Item

Details

Setup

Initialize the file system. It is required when the management data

of the file system corrupts and when read errors occur.

Hard Disk Test

Read Verify)

Perform the Read verify diagnostics of all the sectors in designated

partitions. Sector numbers where a read error is occurring will

appear.

Troubleshooting

Perform the hard disk ROM check and controller diagnostics.

Trouble Prediction

Perform the SMART (Self-monitoring analysis and reporting tech-

nology) to predict latent troubles on the hard disk.

Summary of Contents for DocuColor 1632

Page 4: ...6 02 2 DC1632 2240 Prelaunch Training Review Introduction ...

Page 9: ...6 02 vii DC1632 2240 Introduction Prelaunch Training Review Translated Warnings ...

Page 22: ...6 02 xx DC1632 2240 Prelaunch Training Review Introduction ...

Page 24: ...6 02 1 2 DC1632 2240 Prelaunch Training Review Service Call Procedures ...

Page 38: ...6 02 2 8 DC1632 2240 Prelaunch Training Review Status Indicator RAPs ...

Page 44: ...6 02 2 14 DC1632 2240 1 306 Prelaunch Training Review Status Indicator RAPs ...

Page 452: ...6 02 3 2 DC1632 2240 Prelaunch Training Review Image Quality ...

Page 474: ...6 02 3 24 DC1632 2240 Image Quality Specifications Prelaunch Training Review Image Quality ...

Page 486: ...6 02 4 12 DC1632 2240 REP 1 13 Prelaunch Training Review Repairs and Adjustments ...

Page 490: ...6 02 4 16 DC1632 2240 REP 4 4 Prelaunch Training Review Repairs and Adjustments ...

Page 514: ...6 02 4 40 DC1632 2240 REP 5 19 Prelaunch Training Review Repairs and Adjustments ...

Page 568: ...6 02 4 94 DC1632 2240 REP 9 27 Prelaunch Training Review Repairs and Adjustments ...

Page 572: ...6 02 4 98 DC1632 2240 REP 10 3 Prelaunch Training Review Repairs and Adjustments ...

Page 616: ...6 02 4 142 DC1632 2240 REP 12 20 Prelaunch Training Review Repairs and Adjustments ...

Page 624: ...6 02 4 150 DC1632 2240 REP 14 11 REP 14 12 Prelaunch Training Review Repairs and Adjustments ...

Page 638: ...6 02 4 164 DC1632 2240 ADJ 6 1 Prelaunch Training Review Repairs and Adjustments ...

Page 660: ...6 02 4 186 DC1632 2240 ADJ 12 1 Prelaunch Training Review Repairs and Adjustments ...

Page 766: ...6 02 6 2 DC1632 2240 Prelaunch Training Review General Procedures and Information ...

Page 864: ...6 02 7 2 DC1632 2240 Prelaunch Training Review Wiring Data ...

Page 904: ...6 02 7 42 DC1632 2240 Plug Jack Locations Prelaunch Training Review Wiring Data ...

Page 906: ...6 02 7 44 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 2 ACN Wirenet ...

Page 907: ...6 02 7 45 DC1632 2240 Wirenets Wiring Data Prelaunch Training Review Figure 3 3 3VDC Wirenet ...

Page 917: ...6 02 7 55 DC1632 2240 Wirenets Wiring Data Prelaunch Training Review Figure 13 24VDC 1 of 4 ...

Page 918: ...6 02 7 56 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 14 24VDC 2 of 4 ...

Page 919: ...6 02 7 57 DC1632 2240 Wirenets Wiring Data Prelaunch Training Review Figure 15 24VDC 3 of 4 ...

Page 920: ...6 02 7 58 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 16 24VDC 4 of 4 ...

Page 921: ...6 02 7 59 DC1632 2240 Wirenets Wiring Data Prelaunch Training Review Figure 17 24V RTN 1 of 4 ...

Page 922: ...6 02 7 60 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 18 24V RTN 2 of 4 ...

Page 926: ...6 02 7 64 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 22 IIT 24V RTN ...

Page 928: ...6 02 7 66 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 24 DADF 5V RTN ...

Page 936: ...6 02 7 74 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data ...

Page 939: ...6 02 7 77 DC1632 2240 Chain 01 Wiring Data Prelaunch Training Review Figure 3 LVPS Control ...

Page 946: ...6 02 7 84 DC1632 2240 Chain 01 Prelaunch Training Review Wiring Data Figure 10 Monitoring ...

Page 948: ...6 02 7 86 DC1632 2240 Chain 02 Prelaunch Training Review Wiring Data Figure 2 LCD Control ...

Page 955: ...6 02 7 93 DC1632 2240 Chain 03 Wiring Data Prelaunch Training Review Figure 7 PWS Interface ...

Page 956: ...6 02 7 94 DC1632 2240 Chain 03 Prelaunch Training Review Wiring Data Figure 8 Billing ...

Page 957: ...6 02 7 95 DC1632 2240 Chain 03 Wiring Data Prelaunch Training Review Figure 9 Monitoring ...

Page 969: ...6 02 7 107 DC1632 2240 Chain 06 Wiring Data Prelaunch Training Review Figure 2 Image Input ...

Page 1001: ...6 02 7 139 DC1632 2240 Chain 08 Wiring Data Prelaunch Training Review Figure 5 Registration ...

Page 1002: ...6 02 7 140 DC1632 2240 Chain 08 Prelaunch Training Review Wiring Data Figure 6 Monitoring ...

Page 1012: ...6 02 7 150 DC1632 2240 Chain 09 Prelaunch Training Review Wiring Data Figure 10 Development Y ...

Page 1013: ...6 02 7 151 DC1632 2240 Chain 09 Wiring Data Prelaunch Training Review Figure 11 Development M ...

Page 1014: ...6 02 7 152 DC1632 2240 Chain 09 Prelaunch Training Review Wiring Data Figure 12 Development C ...

Page 1029: ...6 02 7 167 DC1632 2240 Chain 09 Wiring Data Prelaunch Training Review Figure 27 Stripping ...

Page 1032: ...6 02 7 170 DC1632 2240 Chain 09 Prelaunch Training Review Wiring Data Figure 30 IBT Cleaning ...

Page 1042: ...6 02 7 180 DC1632 2240 Chain 10 Prelaunch Training Review Wiring Data Figure 3 Fusing ...

Page 1046: ...6 02 7 184 DC1632 2240 Chain 10 Prelaunch Training Review Wiring Data Figure 7 Duplex Drive ...

Page 1047: ...6 02 7 185 DC1632 2240 Chain 10 Wiring Data Prelaunch Training Review Figure 8 Monitoring ...

Page 1055: ...6 02 7 193 DC1632 2240 Chain 12 Wiring Data Prelaunch Training Review Figure 8 Staple Control ...

Page 1056: ...6 02 7 194 DC1632 2240 Chain 12 Prelaunch Training Review Wiring Data Figure 9 Set Eject ...