6/02

6-3

DC1632/2240

Entering Diagnostic Mode using the PWS

General Procedures and Information

Prelaunch Training/Review

Entering Diagnostic Mode using the PWS

Procedure

The following procedure describe how to enter the Diagnostics Mode with the PWS.

1.

Inform the customer that the machine will be undergoing service and will not be available.

(Copy jobs and local print jobs will be stopped).

2.

Disconnect the machine from the customer network.

3.

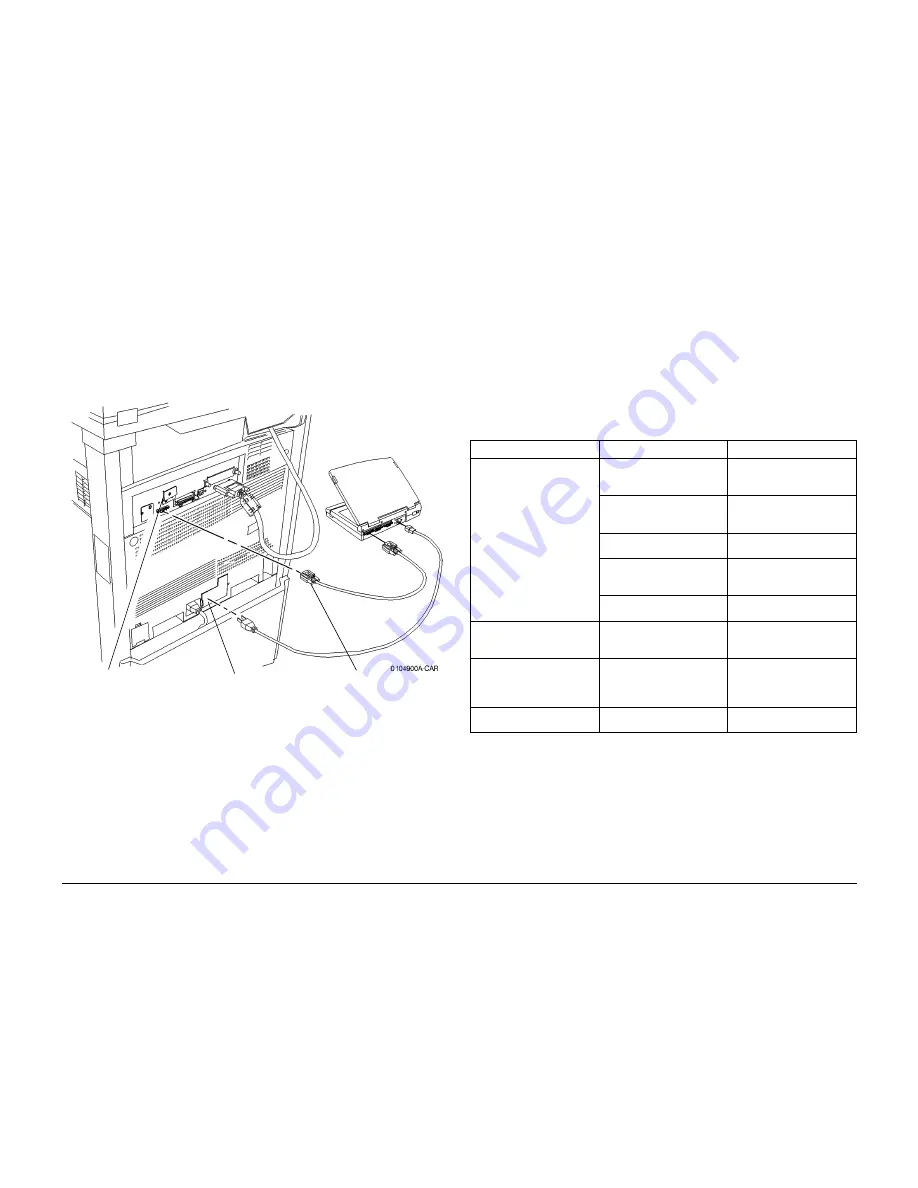

Connect the Portable Work Station (PWS) to the machine (

Figure 1

).

Figure 1 Connecting the PWS

4.

Switch on the PWS.

5.

Make sure the machine is not copying or printing. The machine UI should display

Ready

to Copy

when there are no pending jobs.

6.

At the PWS, enter the

GSNLock Password

and select

OK

.

7.

From the Start menu in the lower left corner, select Programs\Xerox Applications\DC

1632 PWS Tools.

NOTE: The PWS cannot connect to the machine if it is in Power Save mode. Ensure that the

machine indicates Ready to Copy before launching the PWS Tools.

8.

The

Diagnostics Tool screen

will display.

a.

Select

Use Local DB

from the

Diagnostics Tool screen

. The

PWS Diagnostic

Service Entry Window

displays.

b.

While the machine is connected to the PWS, the machine UI will display the mes-

sage,

Connecting to the Machine

.

9.

When the tool starts obtaining machine data, that data is displayed on the Service Entry

Screen. When the system has obtained the machine data, it displays

Complete

at the

upper left corner of the Service Entry Screen.

The data listed in

Table 1

will be displayed.

10. If communication is lost between the PWS and the machine, click

Reconnect

from the

main file menu.

11. To exit the Diagnostic Mode:

a.

Select the

Service Exit Tab

.

b.

Click on the appropriate close-out buttons:

ï

Complete Closeout

ï

Temporary Closeout

c.

After the PWS has disconnected from the machine, select

Exit PWS

to close the

tool.

2

Loosen screw and rotate

plate

1

Remove cover and con-

nect PWS power cord

3

Connect serial

cable

Table 1 Machine Data displayed at Service Entry

Heading

Contents

Description

Machine Data

Product Code

Displays a code allocated to

each machine to identify the

machine.

Serial Number

Displays a 6-digit number (0-

9) allocated to each machine

type to identify the machine.

Total Copies

Displays the total number of

copies/prints

Copies Since Last Call

Displays the total number of

copies/prints since the last

CSE visit (complete closeout).

Software Version

Displays current IOT S/W Ver-

sion

Non-Zero Jams

ID, Description, Occurrences

Displays the Jams that have

occurred since the last com-

plete closeout.

HFSI Requiring Replacement ID, Description, Threshold,

Count.

Displays the component(s)

(HFSI) that has exceeded the

life Threshold).

Faults in Progress (Current

Faults)

ID, Description, Primary

Displays current (active) faults

in the machine.

Summary of Contents for DocuColor 1632

Page 4: ...6 02 2 DC1632 2240 Prelaunch Training Review Introduction ...

Page 9: ...6 02 vii DC1632 2240 Introduction Prelaunch Training Review Translated Warnings ...

Page 22: ...6 02 xx DC1632 2240 Prelaunch Training Review Introduction ...

Page 24: ...6 02 1 2 DC1632 2240 Prelaunch Training Review Service Call Procedures ...

Page 38: ...6 02 2 8 DC1632 2240 Prelaunch Training Review Status Indicator RAPs ...

Page 44: ...6 02 2 14 DC1632 2240 1 306 Prelaunch Training Review Status Indicator RAPs ...

Page 452: ...6 02 3 2 DC1632 2240 Prelaunch Training Review Image Quality ...

Page 474: ...6 02 3 24 DC1632 2240 Image Quality Specifications Prelaunch Training Review Image Quality ...

Page 486: ...6 02 4 12 DC1632 2240 REP 1 13 Prelaunch Training Review Repairs and Adjustments ...

Page 490: ...6 02 4 16 DC1632 2240 REP 4 4 Prelaunch Training Review Repairs and Adjustments ...

Page 514: ...6 02 4 40 DC1632 2240 REP 5 19 Prelaunch Training Review Repairs and Adjustments ...

Page 568: ...6 02 4 94 DC1632 2240 REP 9 27 Prelaunch Training Review Repairs and Adjustments ...

Page 572: ...6 02 4 98 DC1632 2240 REP 10 3 Prelaunch Training Review Repairs and Adjustments ...

Page 616: ...6 02 4 142 DC1632 2240 REP 12 20 Prelaunch Training Review Repairs and Adjustments ...

Page 624: ...6 02 4 150 DC1632 2240 REP 14 11 REP 14 12 Prelaunch Training Review Repairs and Adjustments ...

Page 638: ...6 02 4 164 DC1632 2240 ADJ 6 1 Prelaunch Training Review Repairs and Adjustments ...

Page 660: ...6 02 4 186 DC1632 2240 ADJ 12 1 Prelaunch Training Review Repairs and Adjustments ...

Page 766: ...6 02 6 2 DC1632 2240 Prelaunch Training Review General Procedures and Information ...

Page 864: ...6 02 7 2 DC1632 2240 Prelaunch Training Review Wiring Data ...

Page 904: ...6 02 7 42 DC1632 2240 Plug Jack Locations Prelaunch Training Review Wiring Data ...

Page 906: ...6 02 7 44 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 2 ACN Wirenet ...

Page 907: ...6 02 7 45 DC1632 2240 Wirenets Wiring Data Prelaunch Training Review Figure 3 3 3VDC Wirenet ...

Page 917: ...6 02 7 55 DC1632 2240 Wirenets Wiring Data Prelaunch Training Review Figure 13 24VDC 1 of 4 ...

Page 918: ...6 02 7 56 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 14 24VDC 2 of 4 ...

Page 919: ...6 02 7 57 DC1632 2240 Wirenets Wiring Data Prelaunch Training Review Figure 15 24VDC 3 of 4 ...

Page 920: ...6 02 7 58 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 16 24VDC 4 of 4 ...

Page 921: ...6 02 7 59 DC1632 2240 Wirenets Wiring Data Prelaunch Training Review Figure 17 24V RTN 1 of 4 ...

Page 922: ...6 02 7 60 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 18 24V RTN 2 of 4 ...

Page 926: ...6 02 7 64 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 22 IIT 24V RTN ...

Page 928: ...6 02 7 66 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data Figure 24 DADF 5V RTN ...

Page 936: ...6 02 7 74 DC1632 2240 Wirenets Prelaunch Training Review Wiring Data ...

Page 939: ...6 02 7 77 DC1632 2240 Chain 01 Wiring Data Prelaunch Training Review Figure 3 LVPS Control ...

Page 946: ...6 02 7 84 DC1632 2240 Chain 01 Prelaunch Training Review Wiring Data Figure 10 Monitoring ...

Page 948: ...6 02 7 86 DC1632 2240 Chain 02 Prelaunch Training Review Wiring Data Figure 2 LCD Control ...

Page 955: ...6 02 7 93 DC1632 2240 Chain 03 Wiring Data Prelaunch Training Review Figure 7 PWS Interface ...

Page 956: ...6 02 7 94 DC1632 2240 Chain 03 Prelaunch Training Review Wiring Data Figure 8 Billing ...

Page 957: ...6 02 7 95 DC1632 2240 Chain 03 Wiring Data Prelaunch Training Review Figure 9 Monitoring ...

Page 969: ...6 02 7 107 DC1632 2240 Chain 06 Wiring Data Prelaunch Training Review Figure 2 Image Input ...

Page 1001: ...6 02 7 139 DC1632 2240 Chain 08 Wiring Data Prelaunch Training Review Figure 5 Registration ...

Page 1002: ...6 02 7 140 DC1632 2240 Chain 08 Prelaunch Training Review Wiring Data Figure 6 Monitoring ...

Page 1012: ...6 02 7 150 DC1632 2240 Chain 09 Prelaunch Training Review Wiring Data Figure 10 Development Y ...

Page 1013: ...6 02 7 151 DC1632 2240 Chain 09 Wiring Data Prelaunch Training Review Figure 11 Development M ...

Page 1014: ...6 02 7 152 DC1632 2240 Chain 09 Prelaunch Training Review Wiring Data Figure 12 Development C ...

Page 1029: ...6 02 7 167 DC1632 2240 Chain 09 Wiring Data Prelaunch Training Review Figure 27 Stripping ...

Page 1032: ...6 02 7 170 DC1632 2240 Chain 09 Prelaunch Training Review Wiring Data Figure 30 IBT Cleaning ...

Page 1042: ...6 02 7 180 DC1632 2240 Chain 10 Prelaunch Training Review Wiring Data Figure 3 Fusing ...

Page 1046: ...6 02 7 184 DC1632 2240 Chain 10 Prelaunch Training Review Wiring Data Figure 7 Duplex Drive ...

Page 1047: ...6 02 7 185 DC1632 2240 Chain 10 Wiring Data Prelaunch Training Review Figure 8 Monitoring ...

Page 1055: ...6 02 7 193 DC1632 2240 Chain 12 Wiring Data Prelaunch Training Review Figure 8 Staple Control ...

Page 1056: ...6 02 7 194 DC1632 2240 Chain 12 Prelaunch Training Review Wiring Data Figure 9 Set Eject ...