02/2000

4-90

DocuPrint N2025/N2825

REP 12.24, REP 12.25

Initial Issue

Repair-Adjustment

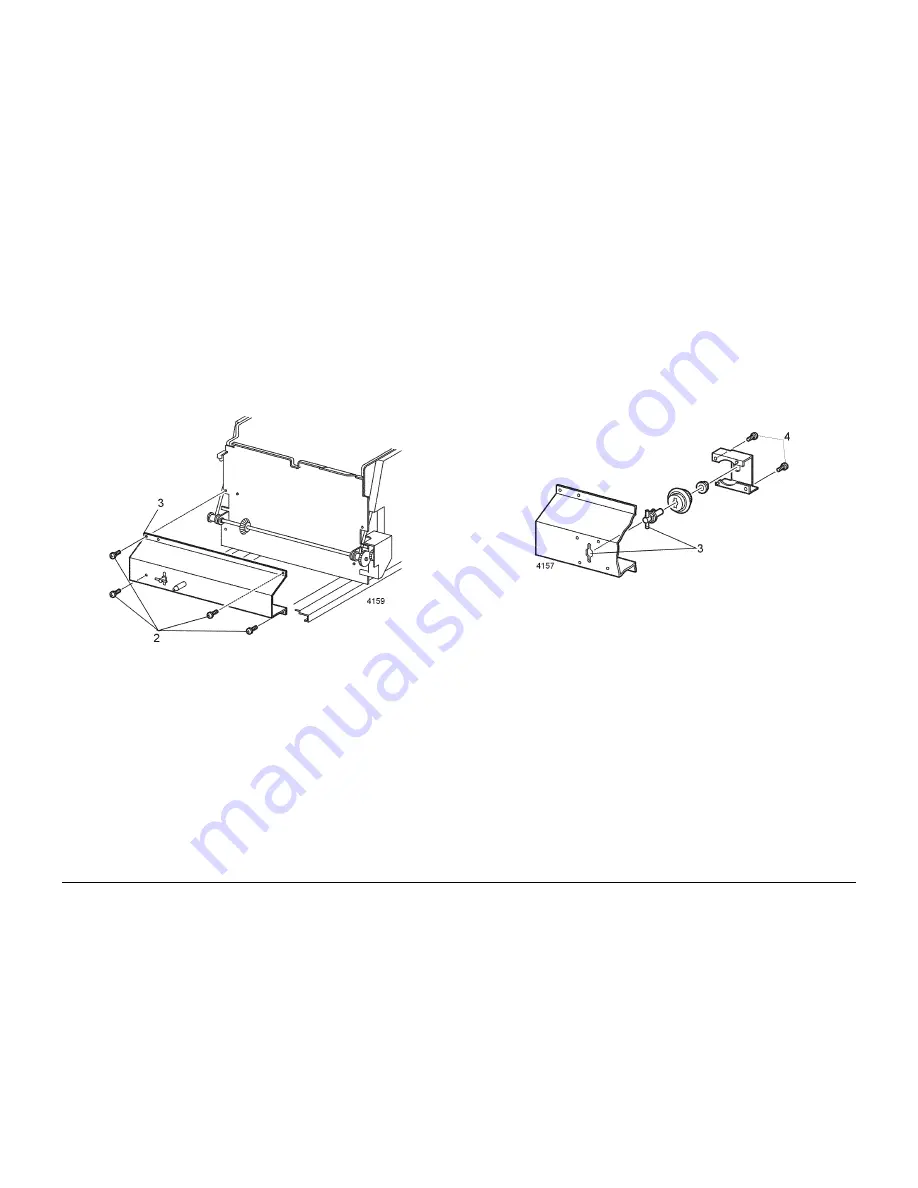

REP 12.24 Shaft Cover Assembly

Parts List on PL 12.4

Removal

WARNING

Switch off the power and disconnect the Power Cord.

1.

Remove the 2000 Sheet Feeder Tray Assembly (REP 12.7).

2.

Remove the four screws that secure the Shaft Cover Assembly to the Tray Assembly (Fig-

ure 1).

3.

Remove the cover (Figure 1).

Figure 1 Shaft Cover Assembly

Replacement

1.

Reinstall the components in the reverse order.

REP 12.25 Drive Shaft Assembly

Parts List on PL 12.4

Removal

WARNING

Switch off the power and disconnect the Power Cord.

1.

Remove the 2000 Sheet Feeder Tray Assembly (REP 12.7).

2.

Remove the Shaft Cover Assembly (REP 12.24).

3.

Align the Drive Shaft Assembly with the hole in the Shaft Cover Assembly (Figure 1).

4.

Remove the two screws that secure the Drive Shaft Bracket to the shaft cover (Figure 1).

5.

Remove the Drive Shaft Assembly.

Figure 1 Drive Shaft Assembly

Replacement

1.

Reinstall the components in the reverse order.

Summary of Contents for DocuPrint N2025

Page 12: ...02 2000 1 2 DocuPrint N2025 N2825 Initial Issue Service Call Procedures...

Page 20: ...02 2000 2 2 DocuPrint N2025 N2825 Initial Issue Status Indicator Repair Analysis Procedures...

Page 86: ...02 2000 3 2 DocuPrint N2025 N2825 Initial Issue Image Quality Repair Analysis Procedures...

Page 114: ...02 2000 4 4 DocuPrint N2025 N2825 Introduction Initial Issue Repair Adjustment...

Page 120: ...02 2000 4 10 DocuPrint N2025 N2825 REP 1 8 REP 1 9 Initial Issue Repair Adjustment...

Page 128: ...02 2000 4 18 DocuPrint N2025 N2825 REP 2 10 REP 2 11 Initial Issue Repair Adjustment...

Page 134: ...02 2000 4 24 DocuPrint N2025 N2825 REP 3 7 Initial Issue Repair Adjustment...

Page 144: ...02 2000 4 34 DocuPrint N2025 N2825 REP 5 5 Initial Issue Repair Adjustment...

Page 152: ...02 2000 4 42 DocuPrint N2025 N2825 REP 7 6 REP 7 7 Initial Issue Repair Adjustment...

Page 160: ...02 2000 4 50 DocuPrint N2025 N2825 REP 8 9 Initial Issue Repair Adjustment...

Page 186: ...02 2000 4 76 DocuPrint N2025 N2825 REP 11 21 REP 11 22 Initial Issue Repair Adjustment...

Page 204: ...02 2000 4 94 DocuPrint N2025 N2825 REP 12 29 Initial Issue Repair Adjustment...

Page 206: ...02 2000 4 96 DocuPrint N2025 N2825 ADJ 1 1 Initial Issue Repair Adjustment...

Page 208: ...02 2000 5 2 DocuPrint N2025 N2825 Initial Issue Parts list...

Page 234: ...02 2000 6 2 DocuPrint N2025 N2825 Initial Issue General Procedures Information...

Page 236: ...02 2000 6 4 DocuPrint N2025 N2825 GP 1 1 Initial Issue General Procedures Information...

Page 274: ...02 2000 6 42 DocuPrint N2025 N2825 GP 3 5 Initial Issue General Procedures Information...

Page 282: ...02 2000 6 50 DocuPrint N2025 N2825 GP 4 8 Initial Issue General Procedures Information...

Page 324: ...02 2000 6 92 DocuPrint N2025 N2825 GP 5 23 Initial Issue General Procedures Information...

Page 326: ...02 2000 6 94 DocuPrint N2025 N2825 GP 6 1 GP 6 2 Initial Issue General Procedures Information...

Page 328: ...02 2000 6 96 DocuPrint N2025 N2825 GP 7 1 Initial Issue General Procedures Information...

Page 330: ...02 2000 6 98 DocuPrint N2025 N2825 GP 8 1 Initial Issue General Procedures Information...

Page 332: ...02 2000 7 2 DocuPrint N2025 N2825 Initial Issue Wiring Data...

Page 361: ...02 2000 7 31 DocuPrint N2025 N2825 Base Engine Wiring Data Initial Issue Figure 16 Figure 17...