General Information

1 - 19

Caution

The actual position of some printer assemblies, such as the

printhead or the cap/wipe/purge assembly, cannot be ascertained

at all times. The printer records, in NVRAM, where it last

positioned such assemblies each time it moves them. If, after

power-down or a power interruption, the assemblies are manually

repositioned, the printer erroneously assumes that the assemblies

are in the position it last left them. This assumption can result in

damage to the printer when it tries to position the assemblies. For

example, the printhead could be tilted forward and crash into the

raised cap/wipe/purge assembly.

Before turning on the printer, ensure the printhead is tilted

forward, centered in front of the drum and the cap/wipe/purge

assembly is in the retracted, home position. The tilt cam gear

should be disengaged from the gear drive train.

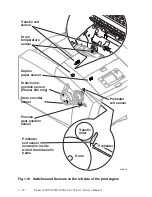

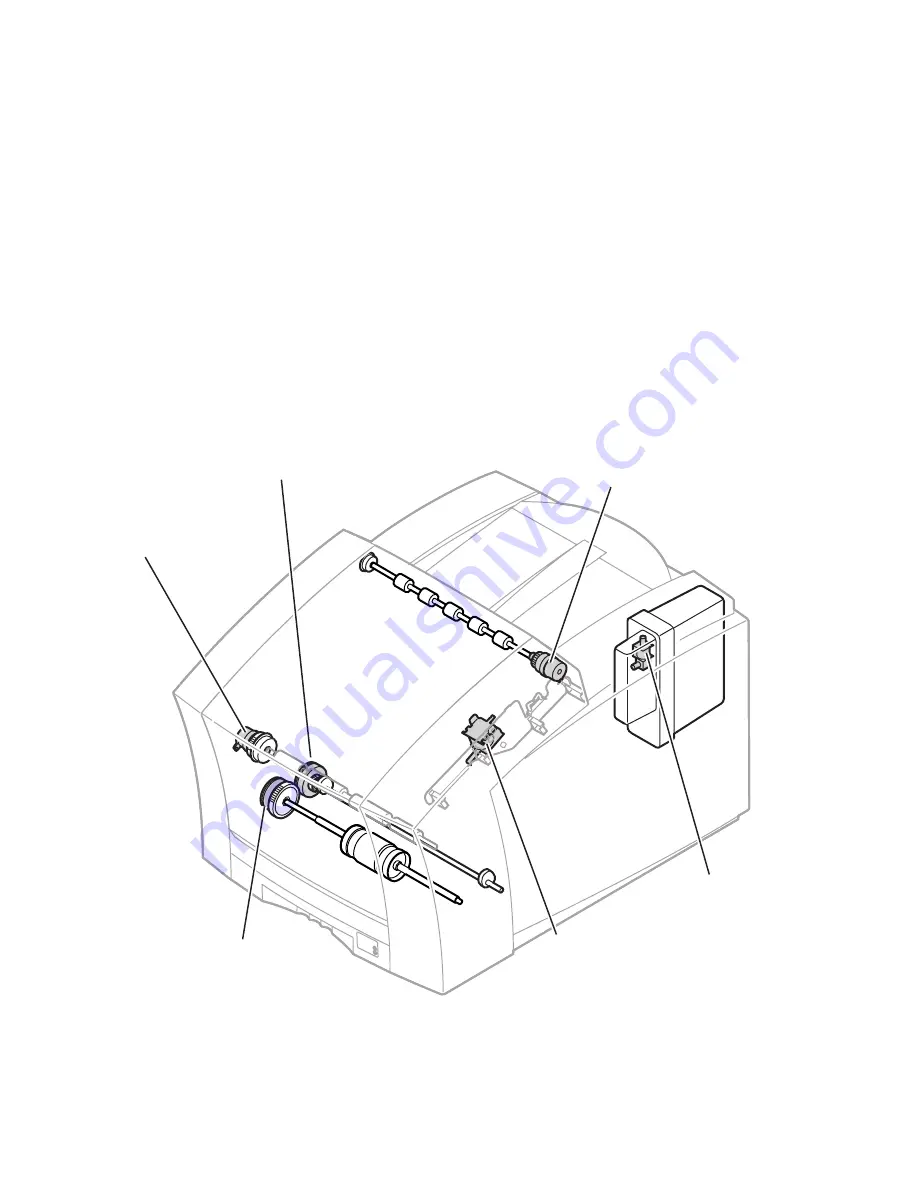

Electric clutches and solenoids are used by the printer to engage rollers as needed to move

paper through the printer as well as start some print processes.

Fig 1-11 Solenoids and clutches on the print engine

Cap/wipe/purge

clutch

Transfix

solenoid

Drum maintenance

cam clutch

Upper feed-

roller clutch

Pick clutch

Air valve

solenoid

0388-08

Summary of Contents for Phaser 840

Page 2: ......

Page 12: ...vi Phaser 840 850 860 8200 Color Printer Service Manual ...

Page 52: ...1 36 Phaser 840 850 860 8200 Color Printer Service Manual ...

Page 88: ...2 72 Phaser 840 850 860 8200 Color Printer Service Manual Blank Page ...

Page 134: ...3 118 Phaser 840 850 860 8200 Color Printer Service Manual ...

Page 174: ...4 158 Phaser 840 850 860 8200 Color Printer Service Manual ...

Page 188: ......

Page 250: ...8 234 Phaser 840 850 860 8200 Color Printer Service Manual ...

Page 286: ...270 Phaser 840 850 860 8200 Color Printer Service Manual ...

Page 287: ...071 0723 00 ...