WorkCentre Pro 423/428

4-36

CHAPTER 4 DISASSEMBLY/ASSEMBLY AND ADJUSTMENT

03/02

4.2 Disassembly and Assembly

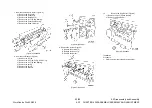

REP 11.4.2 MSI Retard Roll

Ref. PL PL11.4

Removal

On printer or Fax-equipped machines, ensure that

outstanding jobs have cleared before servicing or

interrupting the power to the machine as follows:.

•

FAX equipped machines: Ensure that the “Job in

Memory” indicator on the control panel goes out.

Press “Job Status:Stop” button and confirm that the

job has cleared from the “Current Jobs” folder.

•

Printer machines: Ensure that “Ready to print or

fax” is indicated on the printer control panel.

WARNING

Switch off the machine and disconnect the

power cord.

Procedure

1. Remove the MSI Assembly. (REP11.1.1)

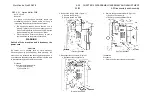

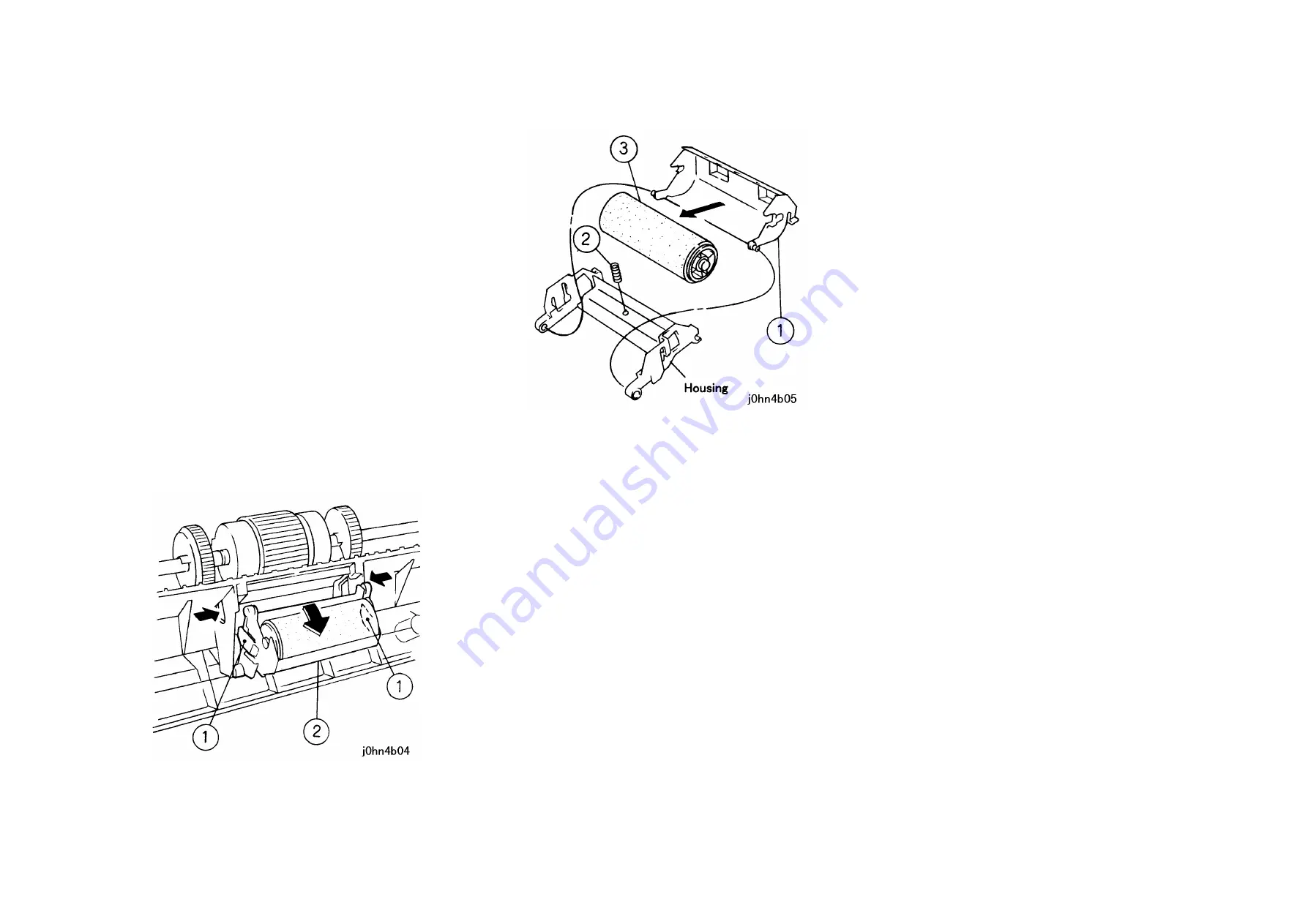

2. Remove the MSI Retard Roll Assembly. (Figure-1)

1) Push in the Hooks on both sides in the

directions of the arrows.

2) Remove the MSI Retard Roll Assembly.

(Figure-1) j0hn4b04

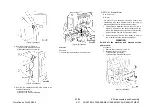

3.

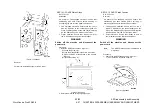

Remove the MSI Retard Roll together with the

Clutch. (Figure-2)

1) Remove the Holder from the Housing.

2) Remove the spring.

3) Remove the MSI Retard Roll with the

clutch.

(Figure-2) j0hn4b05

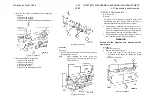

4. Remove the MSI Retard Roll. (Figure-3)

1) Press the Hook in the direction of the arrow.

2) Remove the spring.

3) Extract the Shaft and remove the Retard Roll.

(Figure-3) j0hn4b06

Installation

Procedure

1. Perform the removal steps in reverse order.

13. Finisher

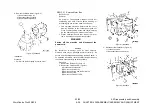

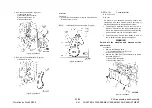

REP 13.1.1 Finisher Assembly

Ref. PL PL13.1

Removal

On printer or Fax-equipped machines, ensure that

outstanding jobs have cleared before servicing or

interrupting the power to the machine as follows:.

•

FAX equipped machines: Ensure that the “Job in

Memory” indicator on the control panel goes out.

Press “Job Status:Stop” button and confirm that the

job has cleared from the “Current Jobs” folder.

•

Printer machines: Ensure that “Ready to print or

fax” is indicated on the printer control panel.

WARNING

Switch off the machine and disconnect the

power cord.

WARNING

The Finisher Assembly weighs 16kg. Be careful

when lifting.

Procedure

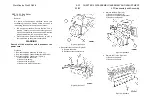

1. Remove the following parts.

1) Finisher Receiving Tray(PL13.18)

2) Finisher Slide Tray (PL13.19)

3) Right Cover Cap A (PL8.3)

4) Right Cover Cap B (PL8.3)

2. Remove the Clamp from the Stay Rear Cover. (Fig.-

1)

1) Remove the Clamp.

Summary of Contents for WorkCentre Pro 423

Page 2: ......

Page 3: ...WorkCentre Pro 423 428 6HUYLFH 0DQXDO...

Page 6: ......

Page 8: ......

Page 9: ...INTRODUCTION...

Page 10: ......

Page 24: ...WorkCentre 423 428 03 02 INTRODUCTION 14 7 Translation of Warnings...

Page 25: ...CHAPTER 1 SERVICE CALL PROCEDURE...

Page 26: ......

Page 28: ...WorkCentre Pro 423 428 1 2 CHAPTER 1 SERVICE CALL PROCEDURE 03 02 1 1 Trimming...

Page 31: ...CHAPTER 2 TROUBLESHOOTING...

Page 32: ......

Page 76: ...WorkCentre Pro 423 428 2 44 CHAPTER 2 TROUBLESHOOTING 03 02 2 3 Level 2 Troubleshooting...

Page 243: ...CHAPTER 3 IMAGE QUALITY TROUBLESHOOTING...

Page 244: ......

Page 273: ...CHAPTER 4 DISASSEMBLY ASSEMBLY AND ADJUSTMENT...

Page 274: ......

Page 329: ...CHAPTER 5 PARTS LIST...

Page 330: ......

Page 415: ...03 02 5 2 Parts List WorkCentre Pro 423 428 5 85 CHAPTER 5 PARTS LIST...

Page 416: ...CHAPTER 6 GENERAL...

Page 417: ......

Page 456: ...CHAPTER 7 ELECTRICAL WIRING DIAGRAMS...

Page 457: ......

Page 476: ...CHAPTER 8 ACCESSORIES...

Page 477: ......

Page 535: ...WorkCentre Pro 423 428 8 58 CHAPTER 8 ACCESSORIES 03 02 8 22 Stamp Kit Red...

Page 536: ...CHAPTER 9 BSD Block Schematic Diagram...

Page 537: ......

Page 541: ......

Page 542: ......

Page 543: ......

Page 544: ......

Page 545: ......

Page 546: ......

Page 547: ......

Page 548: ......

Page 549: ......

Page 550: ......

Page 551: ......

Page 552: ......

Page 553: ......

Page 554: ......

Page 555: ......

Page 556: ......

Page 557: ......

Page 558: ......

Page 559: ......

Page 560: ......

Page 561: ......

Page 562: ......

Page 563: ......

Page 564: ......

Page 565: ......

Page 566: ......

Page 567: ......

Page 568: ......

Page 569: ......

Page 570: ......

Page 571: ......

Page 572: ......

Page 573: ......

Page 574: ......

Page 575: ......

Page 576: ......

Page 577: ......

Page 578: ......

Page 579: ......

Page 580: ......

Page 581: ......

Page 582: ......

Page 583: ......

Page 584: ......

Page 585: ......

Page 586: ......

Page 587: ......

Page 588: ......

Page 589: ......

Page 590: ......

Page 591: ......

Page 592: ......

Page 593: ......

Page 594: ......

Page 595: ......

Page 596: ......

Page 597: ......

Page 598: ......

Page 599: ......

Page 600: ......

Page 601: ......

Page 602: ......

Page 603: ......

Page 604: ......

Page 605: ......

Page 606: ......

Page 607: ......

Page 608: ......

Page 609: ......

Page 610: ......

Page 611: ......

Page 612: ......

Page 613: ......

Page 614: ......

Page 615: ......

Page 616: ......

Page 617: ......

Page 618: ......

Page 619: ......