Finishing

1. Record all data on the “Start-up Checklist” located

at the back of this manual.

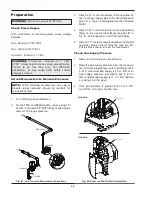

2. Disconnect the manometers and reconnect the

cap on the air intake and reinsert or close the seal-

ing screws into the bleedle valves.

3. Start-up is complete and the boiler should be oper-

ating properly.

Follow-Up

Safety checks must be recorded as performed.

Turn boiler on. After main burner ignition:

1. Check manometer for proper readings.

Specifically note the change in air intake pressure.

Replace the filter if necessary. (Refer to Table X.)

2. Cycle unit several times and re-check readings.

3. Remove all manometers and replace caps and

screws.

4. Check for gas leaks.

Post Start-Up Check

Check off steps as completed:

1. Verify that the boiler and heat distribution units or

storage tank are filled with water.

2. Confirm that the automatic air vent (if used) was

opened two full turns during the venting proce-

dure.

3. Verify that air has been purged from the system.

4. Verify that air has been purged from the gas pip-

ing, and that the piping has been checked for

leaks.

5. Confirm that the proper start-up procedures were

followed.

6. Inspect burner to verify flame.

7. Test safety controls: If boiler is equipped with a low

water cut-off or additional safety controls, test for

operation as outlined by manufacturer. Burner

should be operating and should go off when con-

trols are tested. When safety devices are restored,

burners should re-ignite after pre-purge time

delay.

8. Check to see that the high limit control is set

above the design temperature requirements of the

system. For multiple zones: Check to make sure

the flow is adjusted as required in each zone.

9. Check that the boiler is cycled with the thermostat.

Raise the setting on the thermostat to the highest

setting and verify that the boiler goes through the

normal start-up cycle. Reduce to the lowest set-

ting and verify that the boiler goes off.

48

Safety Inspection

1. Check all thermostats and high limit settings.

2. During the following safety checks leave manome-

ters hooked up, check and record.

3. If other gas-fired appliances in the room are on the

same gas main, check all pressures on the XFyre

with all other equipment running.

4. Check thermostats for ON-OFF operation.

5. Check high limits for ON-OFF operation.

6. While in operation, check flow switch operation.

7. Check the low gas pressure switch (if provided).

(For proper adjustment, use the attached

manometers, if available, to set pressure. The

scales on the switch are approximate only.) Low

gas pressure switch (if provided) must be set at

3.0 in. WC for natural gas and propane gas.

8. Make sure that the high gas pressure switch (op-

tional) is set to 3.0 in. WC for both natural gas and

propane gas.

•

On the first press of the Up button, the test step is

held and "HOLD" is flashed at 1Hz.

•

On the second press of the Up button, the test

step is incremented.

•

If boiler outlet temperature reaches the PIM Hi-

Limit, the boiler will be ramped down to keep the

temperature in a safe range.

• Press of the Up button from Boiler Max will End

the User Test function.

Summary of Contents for 300A

Page 44: ...WIRING DIAGRAM 44...