10

in the following situation, i.e. equalizing charge.

a. The “lag-behind” batteries--- batteries with a voltage lower than that of the other batteries in the charging and

discharging process and the batteries having been repaired for failure. (When equalizing charge is conducted, the

positive and negative poles of the “lag-behind” battery should be respectively connected with the positive and

negative ends of the charger, the DC power supply, and the charge should be conducted independently.).

b. Equalizing charge should be conducted for the batteries in normal use every 2-3 months.

c. Equalizing charge should be conducted for the batteries that have not been used for a long period of time before

use.

8.2.4 Equalizing charge

a. Charge with a 4A current.

b. When the charge voltage reaches 31.2V (12

×

2.6V = 31.2V) and air bubbles occur in the electrolytic solution,

the current should be reduced by 50% (2A) and continue to charge.

c. When the batteries are fully charged, stop charging for 0.5 hour and charge again with a 1A current for one more

hour.

d. Stop charging for another 0.5 hour and charge with a 1A current for another one hour.

e. Repeat according to item d till air bubbles occur violently in the batteries once the charger is switched on.

8.3 Storage

8.3.1 Batteries should be stored in a clean, dry and well ventilated warehouse with a temperature of 5-40

℃

. The valid

shelf life is 2 years. The batteries should be kept according to the following requirements during storage:

a. No direct sunlight on the batteries and at least 2m away from heat source.

b. Avoid contacting with any harmful substances. No metallic matters are allowed to drop into the batteries.

c. The batteries should not be placed upside down and should not be hit mechanically or heavily pressed.

d. The batteries must not be stored with electrolytic solution. When it is required in special situation that the

batteries must be stored with electrolytic solution, the batteries should be fully charged and the density and the

liquid surface of the batteries should be adjusted to the stipulated values. When the storage period comes to one

month, the batteries should be complementarily charged with the common charge method.

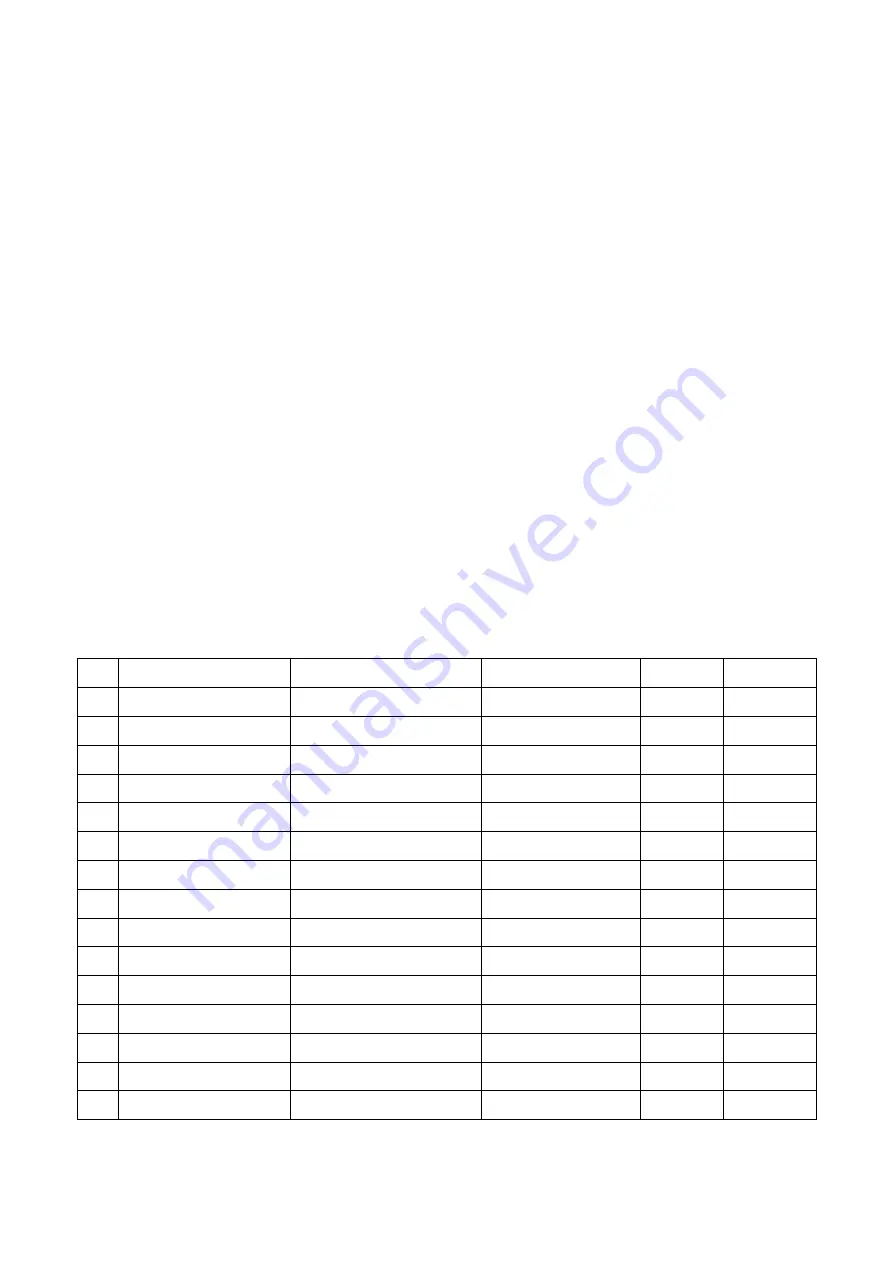

9. List of accessories, spare parts and vulnerable pasts

No.

Name

Use position

Type & specification Quantity

Remarks

1

Key to the electric lock

Unlock the electric lock

2

2

Charging plug and socket Matched with the charger

1 set

3

Fuse

Electric equipment

10A

1

4

Fuse

Electric equipment

160A

1

5

Sealing ring

Lifting oil cylinder

UHS38

2

6

O type sealing ring

Lifting oil cylinder

3.55X50

1

7

Sealing ring

Tilting oil cylinder

UHS30

1

8

Sealing ring

Tilting oil cylinder

UHS63

1

9

O type sealing ring

Tilting oil cylinder

2.56X58

1

10

sealing ring

Forward reach oil cylinder

UHS28

1

11

sealing ring

Forward reach oil cylinder

UHS40

1

12

O type sealing ring

Forward reach oil cylinder

2.65x45

1

13

Dustproof ring

Forward reach oil cylinder

DH28

1

14

Dustproof ring

Tilting oil cylinder

DH30

1

15

Dustproof ring

Lifting oil cylinder

DH38

10. Package & transportation