11

The stacker is packed with a tray. During transportation, turnover and upside-down are not allowed. Collision is not allowed

when lifting and loading onto the truck. Do not damage the outward surface of the stacker when opening the package.

11. Warning (points for attention)

11.1 Read the manual carefully before operation so as to know the performances of the stacker.

11.2 It is forbidden to press and frequently switch the lifting or lowering, otherwise it might damage the stacker and the

goods.

11.3 Do not shake the handle rapidly or with high frequency.

11.4 It is not allowed to rapidly put heavy goods onto the forks.

11.5 The stacker should not be overloaded. When overloaded, the stacker will not be able to operate normally.

11.6 The center of gravity of the goods should be placed between the two forks, otherwise, the forks will be damaged and

the goods will fall down in the process of operation.

11.7 Loose and unstable goods are not allowed to load onto the truck.

11.8 Do not put the goods on the forks for a long period of time.

11.9 Turning rapidly on narrow road is forbidden. In order to ensure the safety of the people and goods, the truck should

turn slowly in this situation.

11.10 When the truck is not in use, the forks should be lowered to the lowest position.

11.11 Never put any part of human body under heavy goods and forks.

11.12 The truck is applicable for use on plane ground and should never be parked on slope for a long period of time.

11.13 Over-load or over-slope operation is forbidden. Otherwise the wheel will slip, damaging the wheel and the motor.

The safety of people and goods will be affected as well.

11.14 It is forbidden to repair the stacker without training.

11.15 Operation of the stacker under the stipulated voltage 20.4V is forbidden.

11.16 It is forbidden to directly connect the plug with AC power supply for charge.

11.17 When lifting height of forks exceeds 500mm, the truck must travel at the minimum speed and the continual traveling

distance must not exceed 2m.

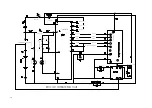

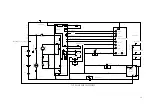

12. Structure diagram (explosion diagram) and principle diagram of

the major parts

See Electric Instructions for “Instruction of the electric system”

See attached diagrams for “The explosion diagram”

13. Packing list

Packing List of CQDH Fork Reach Electric Stacker