5

5.1 Before operation

5.1.1 Before operation, please check if the truck is in normal condition: Is there any oil leakage in the hydraulic pipes? Are

the supporting wheels able to operate normally? Is there any block? Faulty stackers are strictly prohibited.

5.1.2 Check if there is any electric power in the batteries with the method indicated in Fig, I. Pull the general power supply

switch out to turn on the general power supply, unlock the electric lock on the handle, and check the electric energy

meter on the instrument panel of the truck. If one grid at the zero end is bright, it indicates that there is no electric

power in the batteries and charging should be conducted at once. It is prohibited to operate the stacker without

electricity as that will greatly reduce the service life of the batteries and even damage the batteries.

5.1.3 Check if the stacker brake is normal. Check the lifting, lowering, forward and backward extension of fork, and

forward and backward traveling of the truck to see if the actions are normal. Check if the emergency reverse action

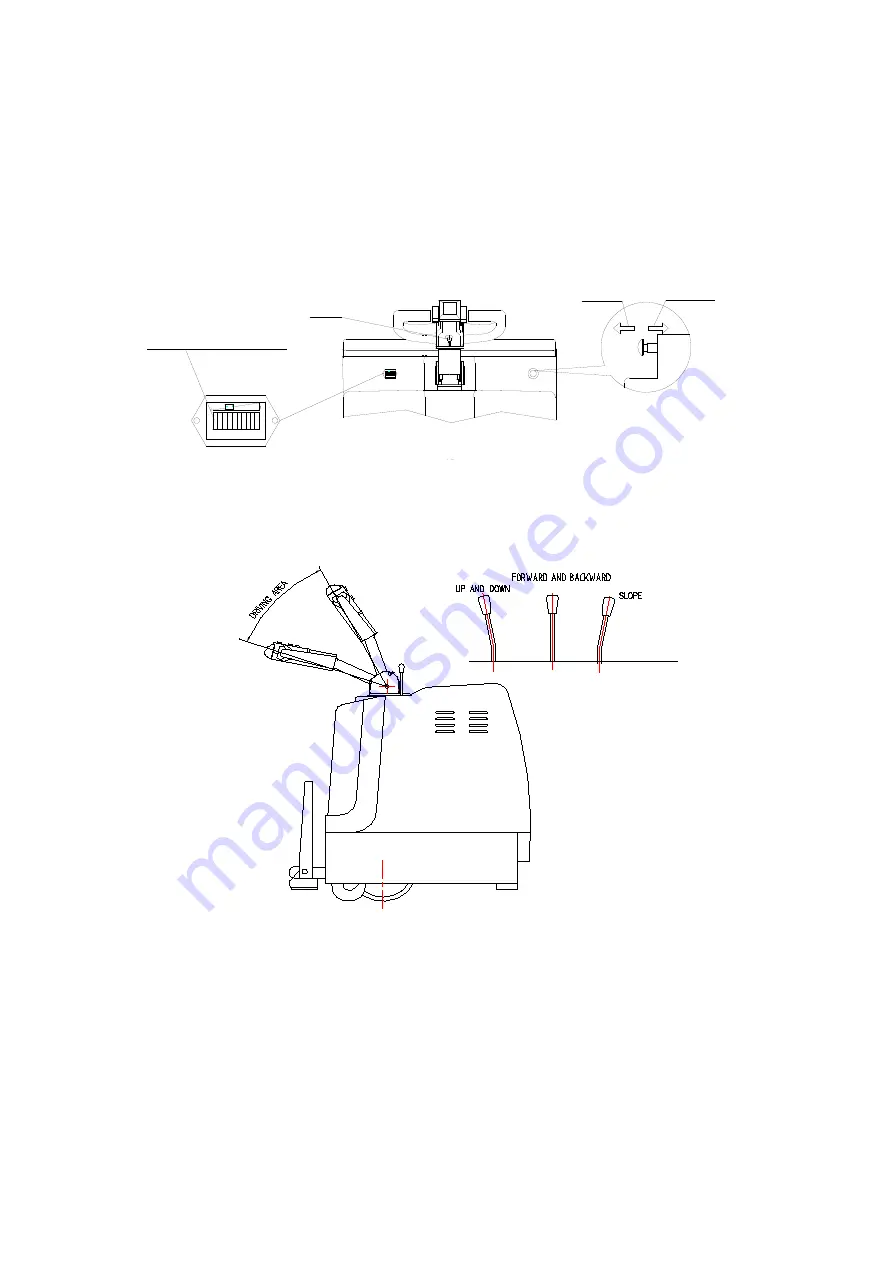

of the stacker is normal with the method indicated in Fig. II:

Fig II

Operating handle is located as indicated in Fig II. Move the steering switch on the accelerator of the operating handle to

see if the stacker can travel forward and backward. Operate the handle of multi-way valve to see if the lifting, lowering and

forward/backward movement of fork is normal.

After the above check, if there is no failure in the stacker, it can be put into use; if there is some failure, please repair at

once. It is prohibited to use faulty trucks.

5.2 In operation

5.2.1 Note: A side-magnetic brake is installed on the shaft end of the driving wheel motor and there is a cam and an

inching switch installed on the rotary shaft of the operating rotary arm. Only when the rotary arm is at 30

°±

20

°

(as indicated in Fig. II), can the truck get power and operate. Larger or less than the angle, the truck has no power

and is braked. In that case, the truck can lift, lower and move the goods forward and backward. When lifting,

lowering and moving the goods, the truck cannot travel as indicated in Fig. II.

Turn on the power supply Turn off the power supply

Electric door lock

There is no electric power in the

batteries if the grid is bright

Fig. I