The K26 SOM 3D CAD files are available for your platform or carrier design reference. These

files are design aides in your cooling mechanical design, system assembly interference and

clearance reviews, and board-to-board (B2B) connector placement alignment checks.

PCB Fabrication and Assembly House

Requirements

The following are requirements for the fabrication of the PC board assembly.

• Carrier card PCB pad-to-pad tolerance should be < ±25 µm.

The blue to red cross (surface pad to surface pad) tolerance with respect to the Gerber pad

location should be less than ±1mil (25 µm).

• Carrier card assembly house placement capability should be < ±26 µm.

• RMS value of the PCB pad-to-pad and component placement tolerance, based on the

capabilities listed above should be < ±36 µm.

• Samtec recommends a tolerance of ±0.04 mm in the distance between the connectors.

• The combination of the all these requirements must be controlled to less than ±40 µm

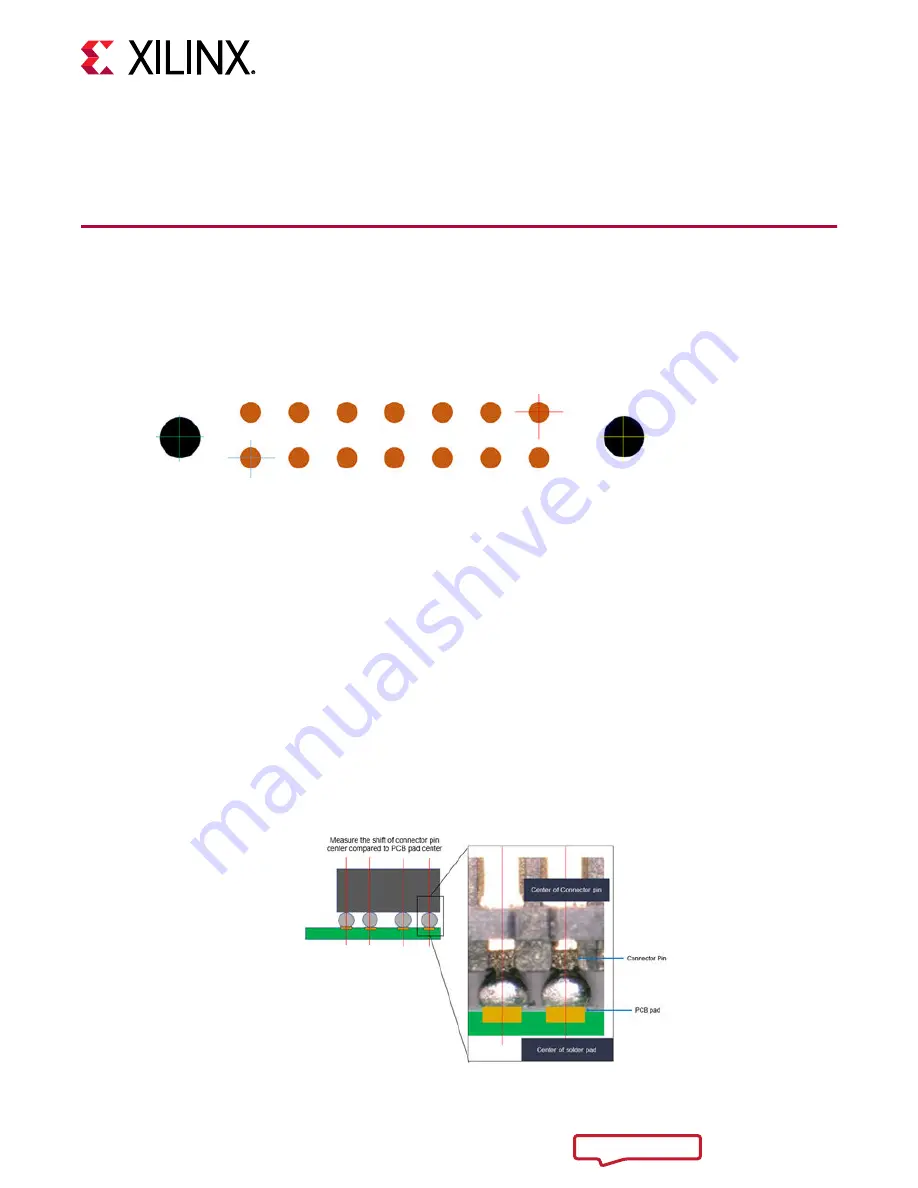

The evaluation of Samtec connector placement is conducted by shifting the placement of the

connector from 0% (PCB pad center aligned with connector pin center) to 15% (pin center offset

by 15% of PCB pad width). The shifted connectors are capable of self-aligning after a reflow

soldering process. The following image shows that even though placement of the connector

shifted by 15% of the pad width, the connector solder ball was still able to self-align to the center

of pad.

Chapter 3: Mechanical Design Considerations

UG1091 (v1.0) April 20, 2021

Carrier Card Design for Kria SOM

39