Fujian Xingyi Polishing Machine Co.,Ltd

Factory:No. 34, Juxian Road, Anping, Anhai Town, Jinjiang City,Quanzhou,Fujian Province, China

Postal Code:362200 Tel: +86-595-36792986 www.xy1118.com

Email:admin@polishingmachine.cc

the first time; for the long-term nonuse of the battery, it should be stored at room temperature

and timely charged to prevent damage caused by self-discharge of the battery (It is

recommended to charge up it once every month).

If you do not use the remote control for a long time, you need to remove the battery.

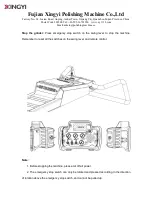

7.3.3 Clean the grinding plate cover

Remove the vacuum tube connection, illuminate the dust nozzle with a flashlight, clean the

dust nozzle with brush. So that it will not clog the dust nozzle and affect dust collection

efficiency.