Mounting tool bits

Warning: before do it, make sure unplug the machine!

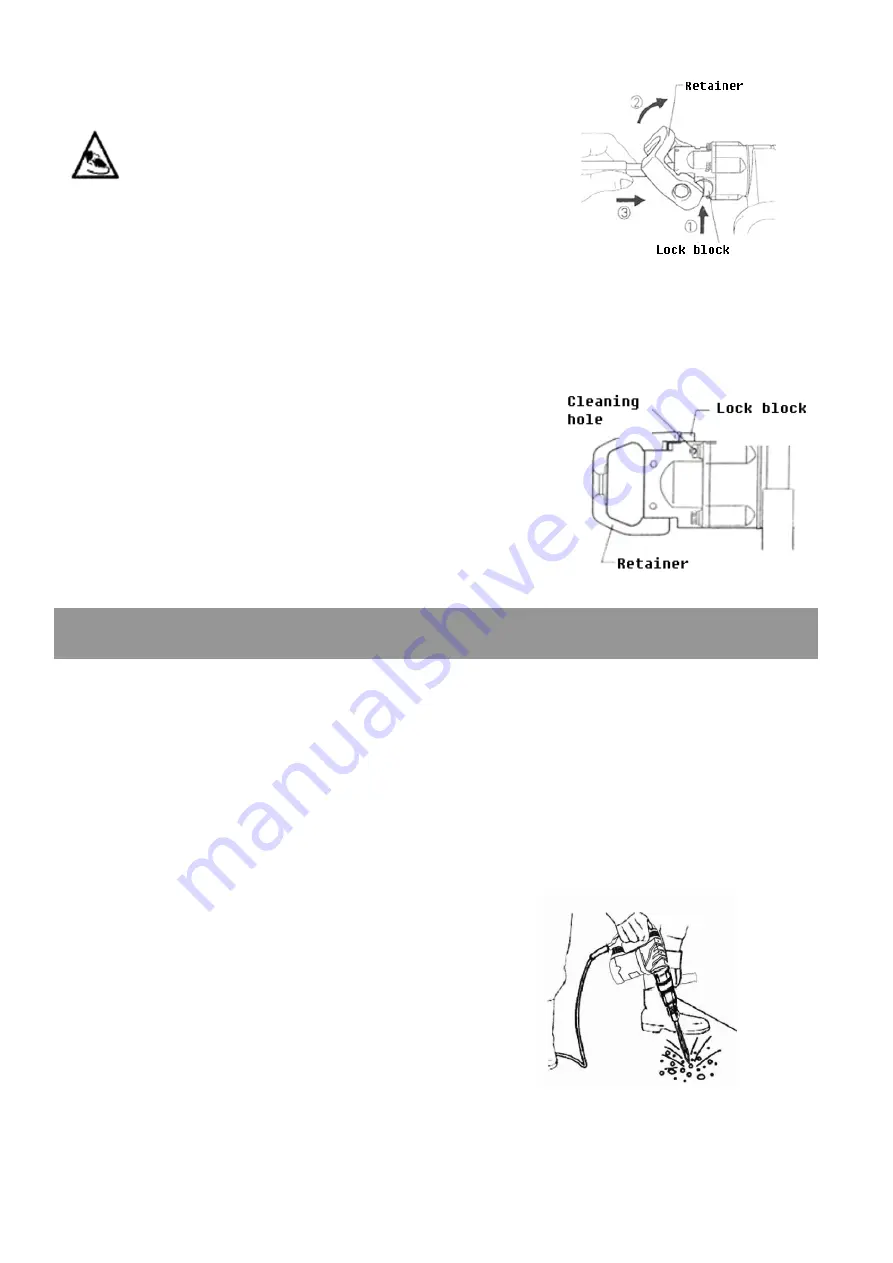

(1)

Please properly press the lock block;

(2) please insert the bit as picture showing

;

(3) put the bit into the bottom, then loose the

lock block and turning the retainer as picture's

opposize direction.

After assembly, pull the bit with force tosure

that have be correctly assembly.

To disassembly, just press the lock block then turn the retainer as picture showing.

(remark

;

all of above operation must on the condition thatthe temperature is not so

high to injur your skin)

When lock block is difficult to operate just

clean the remains and add some oilfrom the

cleaning hole, then turn a few times.

Prior to operation

1. Power source

Ensure that the power source to be utilized conforms to the power requirements which specified

on the name plate of the hammer.

2. Power switch

Ensure that the power switch is in the position of OFF. If the plug is connected to power

receptacle while the power switch is in ON position, the demolition hammer will start operation

immediately, which can cause serious accident!

Operation

1. Switch action

To start the tool, simply pull the trigger.

Release the trigger to stop, for continuous

Operation, pull the trigger and then push in

The lock button, to stop from the locked

Position, just press the trigger fully, then

Release it.

2. Operate this demolition hammer by utilizing extra pressure. The performance will be better if it is

pressed properly against the work surface.

4. Operation