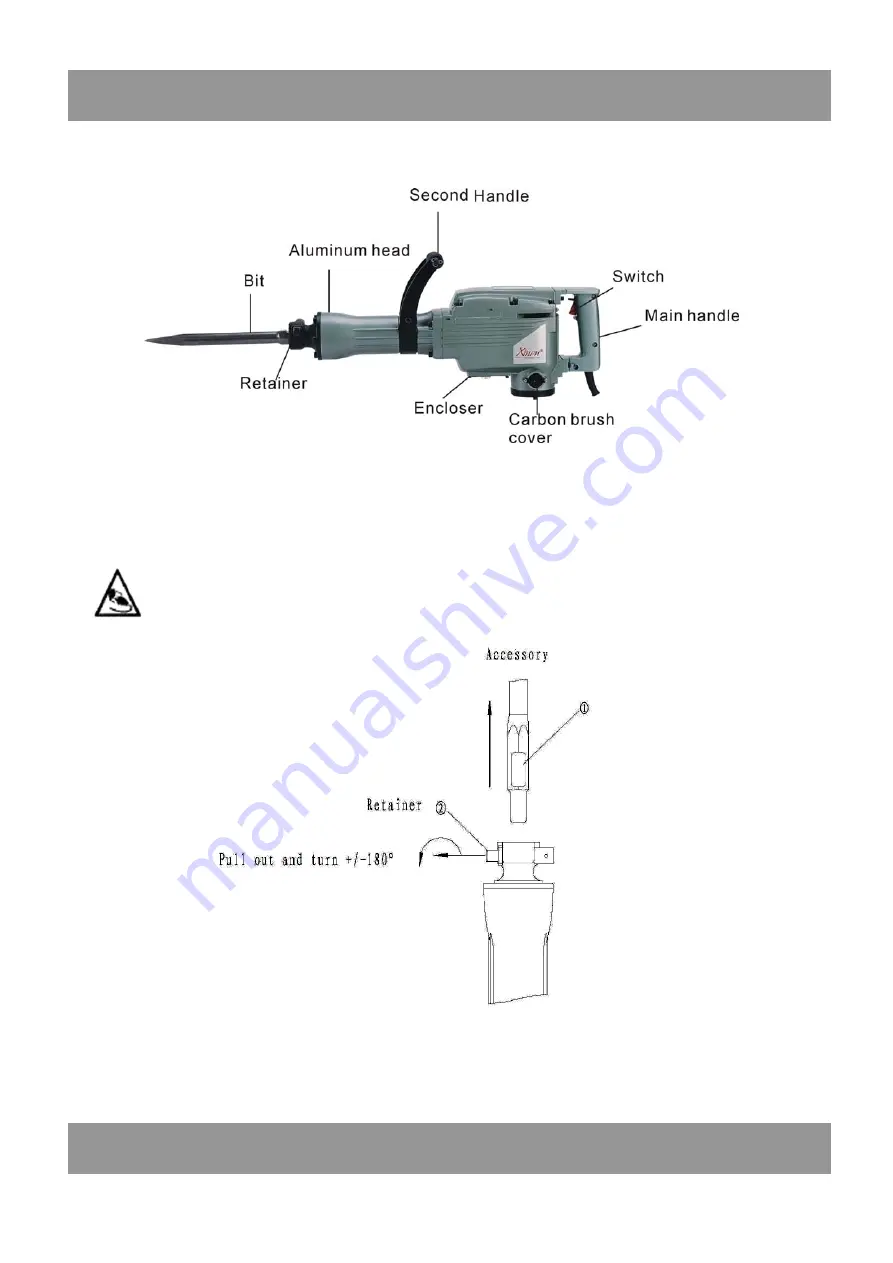

Name of the parts

Mounting tool bits

Warning: before do it, make sure unplug the machine!

(1) Pull out of the retainer "2", turning 180

℃

clockwise or anticlockwise, insert the

accessory shank portion"1" into the hole on the front cover.

(2) Turning the retainer back into original position.

Remarking:

When you removing the accessory, such as a bull point, a cutter etc.., follow above

procedure in reverse order.

3. Assembly

4. Operation