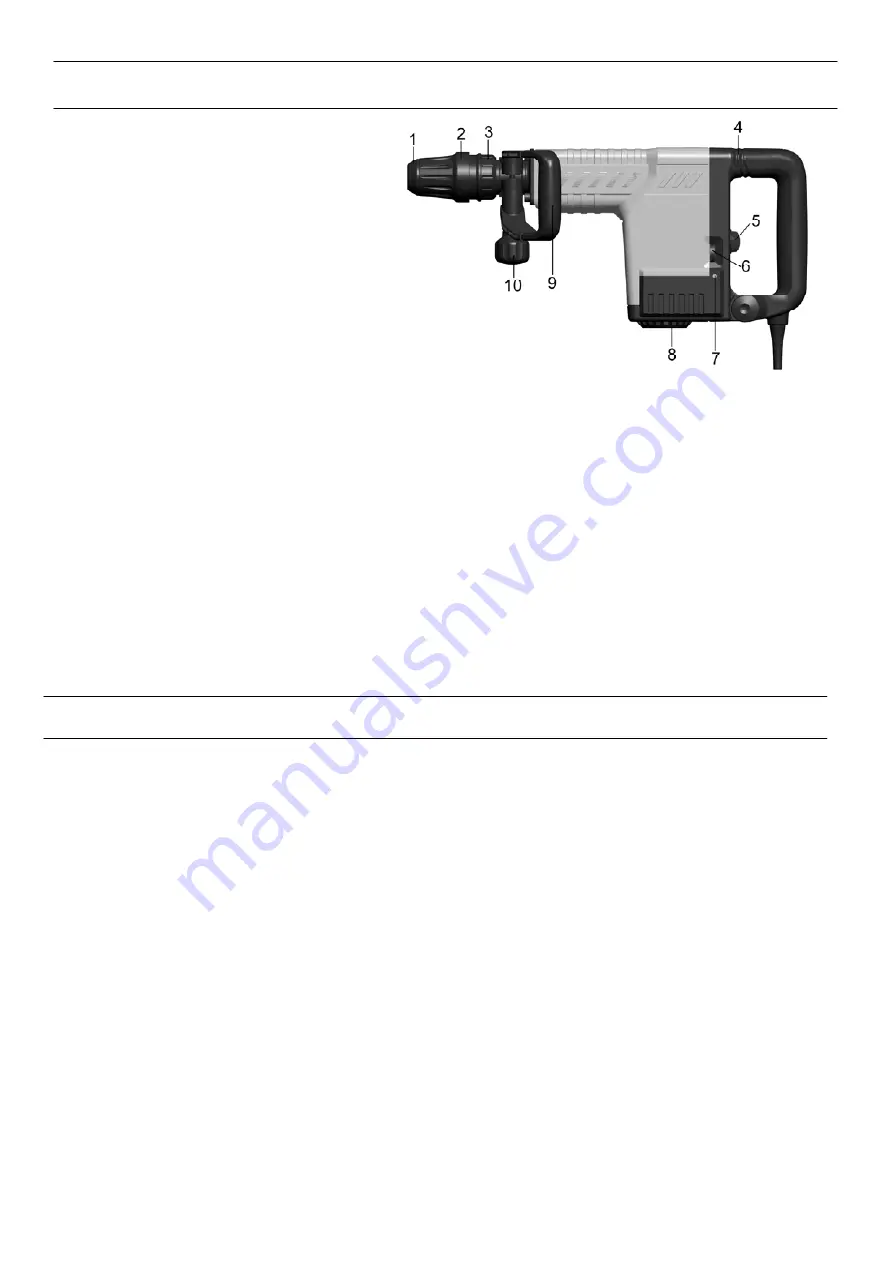

Name of the parts

1.

Hammer rod protector

2.

Protective lining

3.

Move limited ring

4.

Shock Absorption Jacket

5.

Switch

6.

Speed Adjuster Function Knob

7.

Indicator

8.

Fan cover

9.

Side Handle

10.

Function Knob

Prior to operation

1. Power source

Ensure that the power source to be utilized conforms to the power requirements which specified on the

name plate of the hammer.

2. Power switch

Ensure that the power switch is in the position of OFF. If the plug is connected to power receptacle

while the power switch is in ON position, the demolition hammer will start operation immediately,

which can cause serious accident.

3. Extension cord

When the work area is removed from the power source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be kept as short as practicable.

Assembly

Auxiliary Handle

Operate your power tool only with the

Side Handle

9.

The Side Handle 9 can be set to any position for a secure and low-fatigue working posture.

Loosen the Function Knob 10, rotate the Side Handle 9 around the axis of the power tool to the required

position and tighten the Function Knob 10 again.

The Side Handle

9

can be mounted to a different position. For this, completely unscrew the Function

Knob 10 and then pull out the hexagon bolt upward. Pull off the Side Handle 9 to the side and turn around

the remaining clamping element by 18

0

。

Mount the Side Handle 9 in reverse order.

Changing the tool

Before any work on the power tool itself, pull the mains plug.

With the SDS-max tool holder. Simpler and easier tool changing is possible without additional aids.

The Hammer rod protector 1 largely prevents the entry of drilling dust into the tool holder during

operation. When inserting the tool, take care that the Hammer rod protector 1 is not damaged.

A damaged

Hammer rod protector

should be changed immediately.

We recommend having this carried

out by an after-sales service.