XD-9010-TS3-W-EN Rev A 04/2009

Installation & Operation Manual

27

6. TROUBLESHOOTING

6.1. COOKING PROBLEMS

Experimentation is about the only way to determine proper time and temperature settings. While

a pizza may look perfectly cooked on the outside, the inside may be undercooked. A

thermometer is necessary to determine if food items are being properly cooked. Most health

departments have rules and regulations that establish minimum temperatures for internal food

temperatures. Most operators want to cook foods as fast as possible in order to serve more

customers per hour. However, cooking foods slower is the only way to achieve a proper internal

temperature. If your food products look acceptable on the outside, but have an internal

temperature that is too low, then lowering the temperature and decreasing the belt speed (thereby

increasing the cook time), will be necessary.

Several factors may affect the cooking performance and characteristics:

1.

Oven temperature (generally affects color)

2.

Conveyor speed (generally affects doneness)

3.

Finger arrangement

4.

Altitude

5.

Pans versus screens

6.

Dough thickness

7.

Cheese type

8.

Raw ingredient temperature (frozen?)

9.

Quantity of toppings

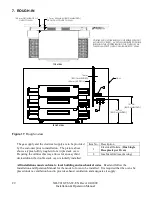

XLT ovens can be configured to cook a wide variety of food items. This is accomplished by

arranging the fingers to control the baking characteristics. Generally speaking, most cooking is a

“bottom up” process. The hot air from the bottom row of fingers has to go through the conveyor

(a distance of about 50.8mm), heat the pan or screen, and then actually cook raw dough. The hot

air from the top, on the other hand, basically only has to melt cheese and re-heat precooked

toppings. Consequently, most operators will use the oven with the fingers arranged so that a lot

more air is directed to the bottom of the pizza than to the top. There are places for an equal

number of fingers above and below the conveyor. Available are finger cover plates that have six

rows of holes, four rows of holes, two rows of holes, and no holes (or blank cover plates). A

typical finger arrangement might have most or even all fingers on the bottom “full open”, that is

fingers with all six rows of holes, and only two or three fingers on top with four or six rows of

holes. The top fingers can be arranged in an symmetrical pattern or can be shifted

asymmetrically to either the entrance or exit end of the conveyor.

We encourage you to experiment by trying different finger arrangements, temperatures, and belt

speeds. Wolfe Electric, Inc. can assist you with your oven/product configurations.