Sin,

le. Sn,art.

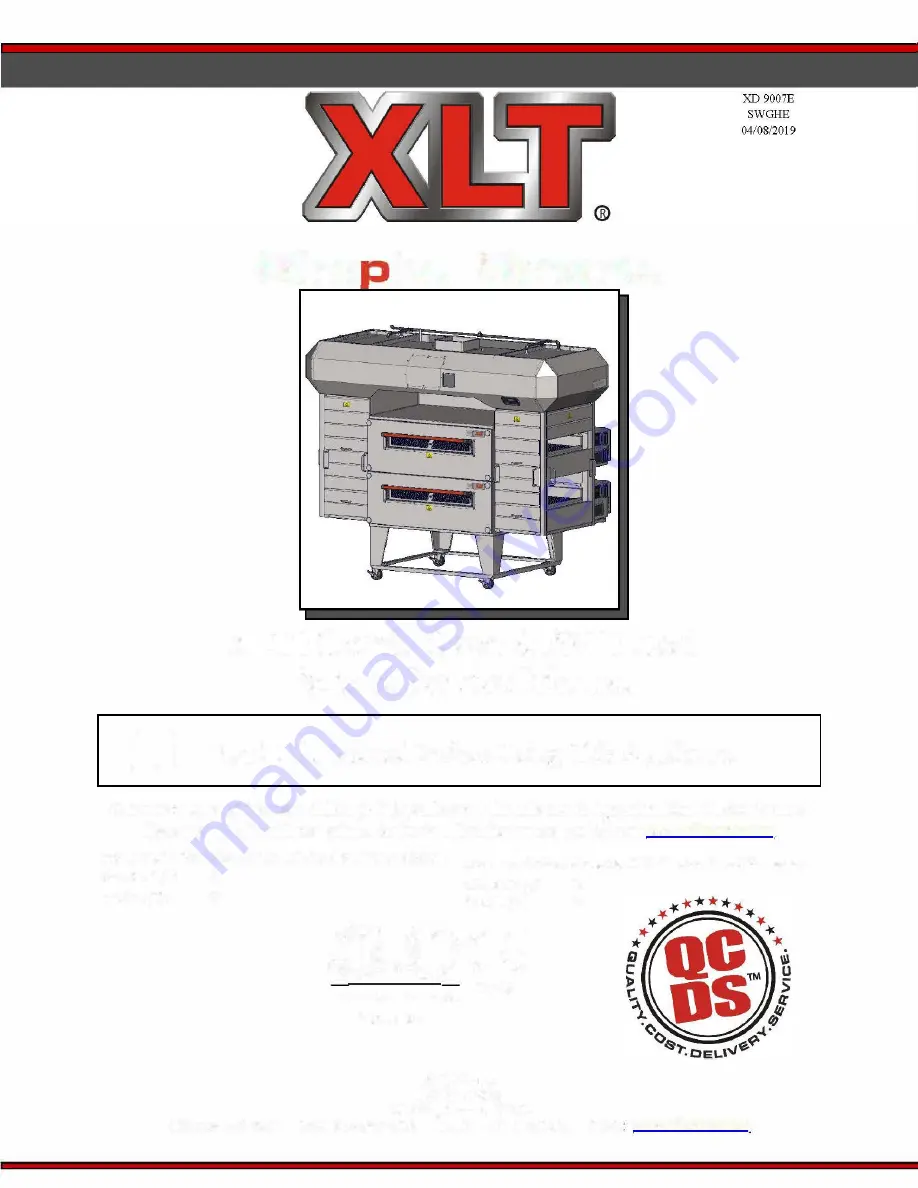

XLT Electric Oven & AVI Hood

Parts & Service Manual

w

Read This Manual Before Using This Appliance.

Current versions of this manual, Rough-In Specifications, Installation & Operation Manual, Architectural

Drawings, & a list oflnternational Authorized Distributors are available at:

www.x

l

tovens.com

For use with the followi

ng

XL T Electric Oven Versions•

For use with the following A VI Electric Hood Versions•

Standard (S)

G

World (W)

G

Standard (S)

E

World(W)

E

,(fil) .. �C E

-l1,an;.O

�

7'JOt

P•-'

lntertek lntertek 0359

2000887

XLI Ovens

PO Box9090

Wichita, Kansas 67277

US• 888-443-2751 FAX 316-943-2769 INTL 316-943-2751 WEB

www

.

x

l

t

ovens

.

com