XD-9010-TS3-S Rev A 04/2009

24

Installation & Operation Manual

5.9.6. MAINTENANCE

The most critical item to be maintained is the filter on the Flow Path Pressure Generating fan (see

Figure 6, page 7). The filter is held in place by a snap-on fan guard and can be washed several times.

Regular cleaning of the Flow Path Pressure Generating fan filter is important to maintaining air

circulation within the control box and providing combustion air. Air circulation will help extend the life

of components and avoid oven down time. Depending upon store conditions, this filter should be cleaned

weekly or as it gets clogged with dust. After several cleanings the filter will need replacement. These can

be ordered directly from XLT at 1-888-443-2751 or can be purchased from your local Grainger store; part

number 4YD83 or 4YD84. Remember, the cleaner the filter, the cooler the control box components

will be, resulting in longer component life.

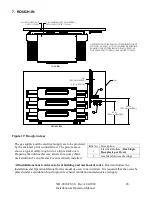

Figure 16: Filter element removal

Contact Wolfe Electric, Inc., a factory representative, or a local service company to perform all other

maintenance and repairs.

5.10. CLEANING

NOTICE:

If the oven is to be removed from its installed location for cleaning or servicing the

following procedure is to be implemented:

1. Shut off main manual gas valve.

2. Unplug electric cord.

3. Unplug gas line.

4. Unlock casters.

5. Disconnect restraint.

6. When servicing or cleaning is complete, move oven to original location.

7. Connect restraint.

8. Lock casters.

9. Plug in electric cord.

10. Plug in gas line.

11. Turn manual gas valve on.

12. Follow normal lighting instructions.

Type A fan covers can be pulled off

from any side. Clean or replace filter.

Type B fan covers can be pried off using

a small screwdriver inserted into a

corner slot. Clean or replace filter.