7

NOTE: Hand tighten bolts and locknuts until machine is fully assembled.

Lock nuts may require additional force to tighten completely.

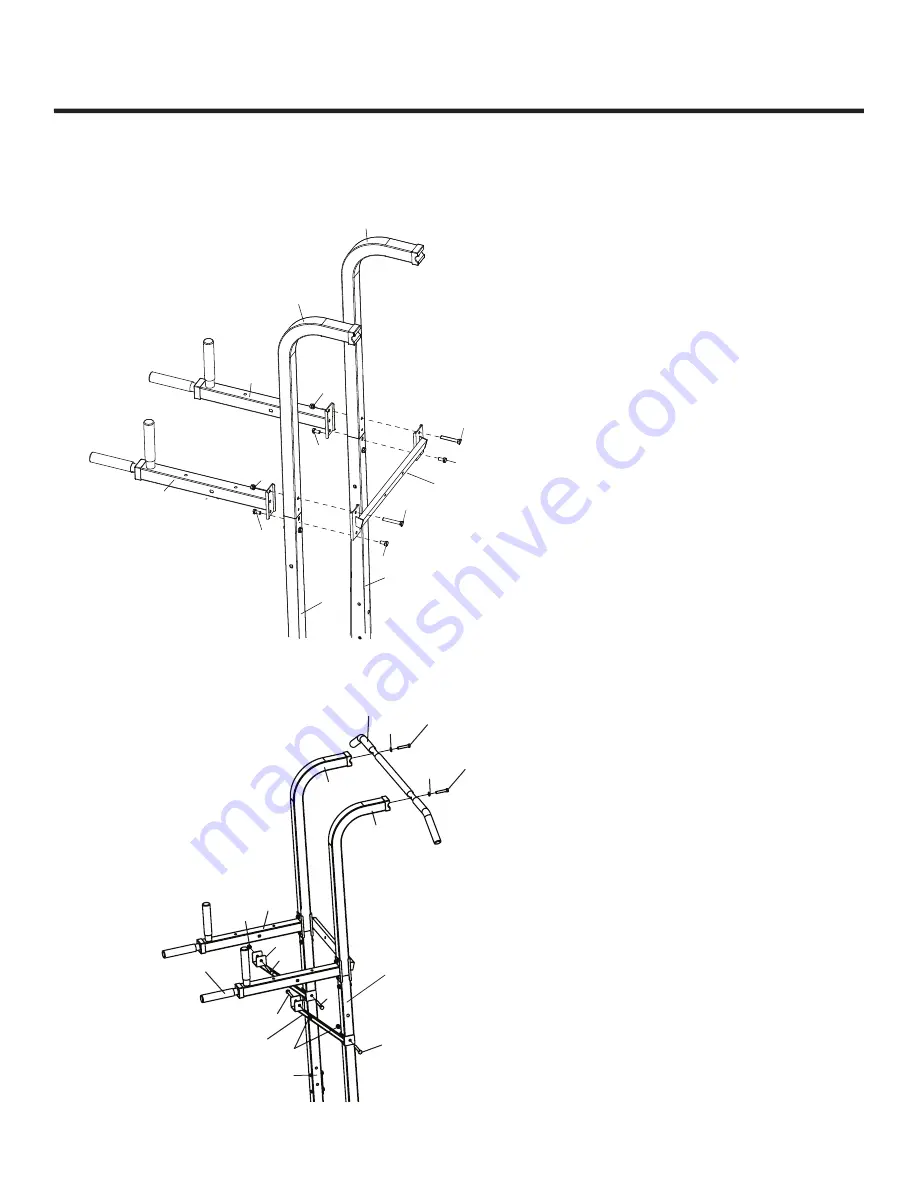

STEP 5

STEP 6

Assembly

C1

C1

13

13

A1

A1

A1

A1

A2

12

11

11

6

6

A2

A2

A2

A2

A3

18

B1

C1

C1

11

11

13

14

14

13

6

6

A3

B1

A2

A1

Attach the Extended Arms (13) through

the joints of the Upper and Lower

Upright Tubes (11 & 6) to the Upper

Cross Brace (12). Secure them with four

M10x20 Bolts (A1), two M10x70 Bolts (A2)

and two M10 Lock Nuts (C1).

Attach the Upper Support Bars (14)

to the Extended Arms (13) and the

Lower Upright Tubes (6). Secure using

four M10x70 Bolts (A2) and four M10

Lock Nuts (C1). Attach the Pull-up Bar (18)

to the Upper Upright Tubes (11) and

secure with two M10x55 Bolts (A3)

and two M10 Washers (B1).