- 15 -

2. CONNECT ELECTRICAL:

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PER-

SONS, OBSERVE THE FOLLOWING: Before making electrical connections to power

supply, the electrical box must be secured in place as indicated in Fig.14.

Before installing the appliance fix the electrical box as indicated in Fig.14.

�

�

�

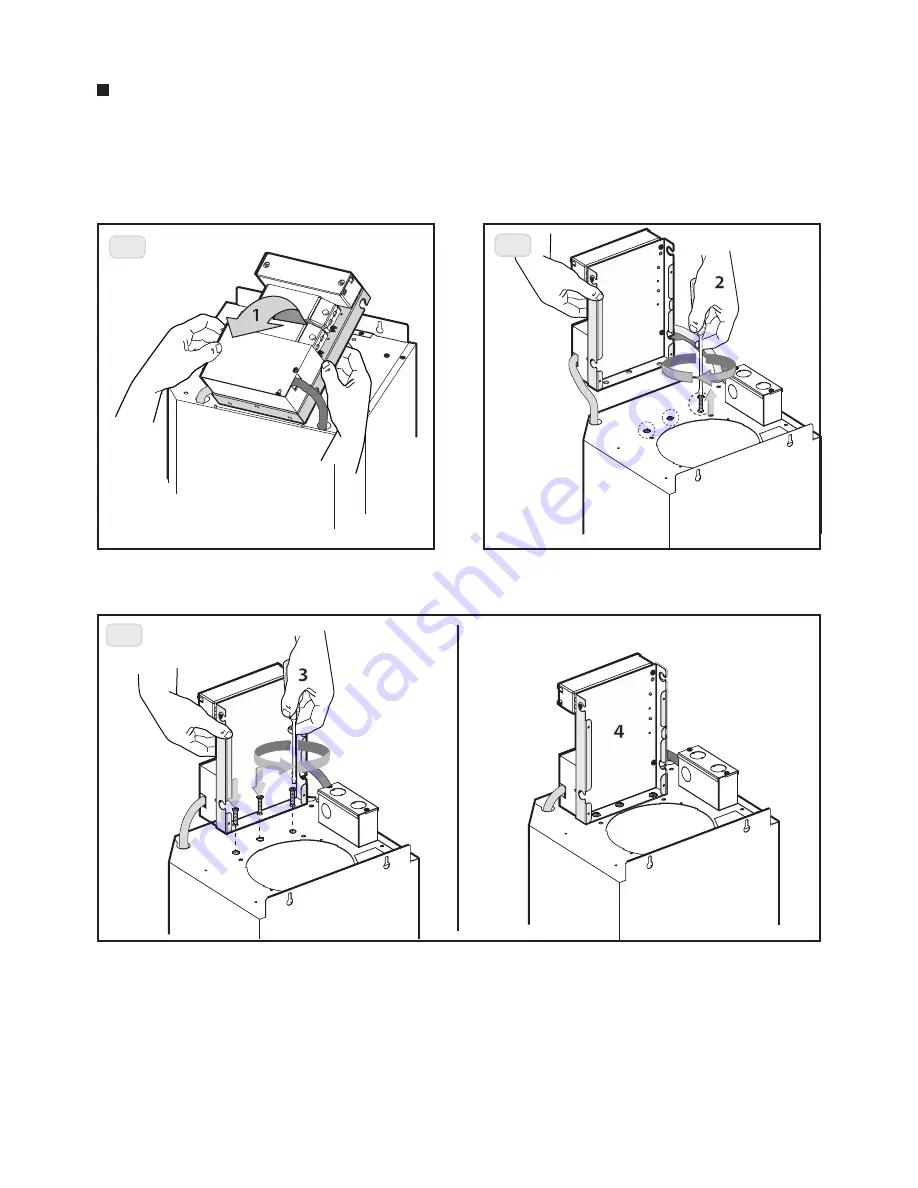

Fig.14B:

Remove the 3 fixed screws.

Fig.14A:

Lift the electrical plant box.

Fig.14C:

Position the electrical box so it is in the line with the holes of the previously

removed screws and tighten.

Summary of Contents for XOMI36G

Page 11: ... 11 Fig 9 Fig 7 Fig 8 ...

Page 25: ... 25 XOMI36G XOMI42G ...