- 16 -

�

�

�

�

�

�

�

�

�

�

�

������

�

� �

����

�

����

���

�

���

��� ���

���

��� ���

���

��� ���

���

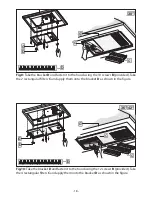

Fig.4: Take the air diverter A and drill two holes as

shown in the figure (hole diameter: 1/4" inches).

Once the two holes have been drilled, fasten the

air diverter A to the bracket H.

Fig.3: Put together the two parts of

the air deviator as shown in picture

no 3.1. It may be necessary to cut

the deviator to fit the width of the

chimney as shown in picture 3.2 A

sharp blade or Hacksaw is recom-

mended to trim the plastic.

Fig.1: Remove the 2 screws E and have the top flue F go

into the bottom flue G. Remove the two flues F/G and

place them on a flat surface.

Fig.2: Make a mark on the

wall and then drill a hole

1/4" inches away from

the middle of the brack-

et. Insert the expansion

plug.