1

Safety precautions

1. Instructions

Be sure to switch off the power supply before replacing or welding any components or

inserting/plugging in connection wire. Anti static measures must be taken (throughout the entire

manufacturing process!):

a) Do not touch here and there by hand at will;

b) Be sure to use anti static electric iron;

c) It’s a must for the welder to wear anti static gloves.

Please refer to the detailed list before replacing components that have special safety requirements.

Do not change the specs and type at will.

2. Points for attention in servicing of LCD

2.1 Screens are different from one model to another and therefore not interchangeable. Be sure to

use the screen of the original model for replacement.

2.2 Be sure to take proper measures in protecting yourself and the machine when testing the

system in the course of normal operation or right after the power is switched off. Please do not

touch the circuit or the metal part of the module that is in operation mode. Relevant operation is

possible only one minute after the power is switched off.

2.3 Do not use any adapter that is not identical with the TV set. Otherwise it will cause fire or

damage to the set.

2.4 Never operate the set or do any installation work in bad environment such as wet bathroom,

laundry, kitchen, or nearby fire source, heating equipment and devices or exposure to sunlight etc.

Otherwise bad effect will result.

2.5 If any foreign substance such as water, liquid, metal slices or other matters happens to fall into

the module, be sure to cut the power off immediately and do not move anything on the module lest it

should cause fire or electric shock due to contact with the high voltage or short circuit.

2.6 Should there be smoke, abnormal smell or sound from the module, please shut the power off at

once. Likewise, if the screen is not working after the power is on or in the course of operation, the

power must be cut off immediately and no more operation is allowed under the same condition.

2.7 Do not pull out or plug in the connection wire when the module is in operation or just after the

power is off because in this case relatively high voltage still remains in the capacitor of the driving

circuit. Please wait at least one minute before the pulling out or plugging in the connection wire.

2.8 When operating or installing LCD please don’t subject the LCD components to bending, twisting

or extrusion, collision lest mishap should result.

2.9 As most of the circuitry in LCD TV set is composed of CMOS integrated circuits, it’s necessary

to pay attention to anti statics. Before servicing LCD TV make sure to take anti static measure and

ensure full grounding for all the parts that have to be grounded.

2.10 There are lots of connection wires between parts behind the LCD screen. When servicing or

moving the set please take care not to touch or scratch them. Once they are damaged the screen

would be unable to work and no way to get it repaired.

If the connection wires, connections or components fixed by the thermotropic glue need to

disengage when service, please soak the thermotropic glue into the alcohol and then pull them out

Attention:

This

service manual is only for service personnel to take reference with. Before

servicing please read the following points carefully.

Summary of Contents for LC-19HU56S

Page 1: ...LCD TELEVISION LC 19HU56S...

Page 11: ...9 6 Select the document then the window will appear as shown below Select...

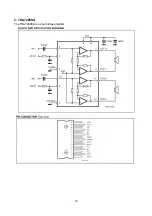

Page 18: ...16 2 TDA7266SA The TDA7266SA is a dual bridge amplifier...

Page 20: ...18...

Page 27: ...Main Board Schematic diagrams Page 1 total 8 pages 25...

Page 28: ...Main Board Schematic diagrams Page 2 total 8 pages 26...

Page 29: ...Main Board Schematic diagrams Page 3 total 8 pages 27...

Page 30: ...Main Board Schematic diagrams Page 4 total 8 pages 28...

Page 31: ...Tuner Board Schematic diagrams Page 5 total 8 pages 29...

Page 32: ...IR Key Board Schematic diagrams Page 6 total 8 pages 30...

Page 33: ...Power Board Schematic diagrams Page 7 total 8 pages 31...

Page 34: ...Back light Board Schematic diagrams Page 8 total 8 pages 32...

Page 36: ...APPENDIX B Exploded view LC 19X56 34...

Page 38: ...9219HU5610 Ver 1 0...