1

1 safety instruction

1.1 X-RAY radiation precaution

1.1.1 Excessive voltage will cause harmful X-ray. To avoid this radiation hazard, the high voltage should

fall within the limitation. The appliance works at AC 120V, 60Hz. The high voltage of zero beam current

should be within 29.0kV on condition that the main power (B+) voltage is AC135V. And it should not

exceed 30kV in any condition.

* Keep the main power voltage at 135V when checking the high voltage.

1.1.2 The primary source of X-RAY RADIATION is the CRT. The CRT of this TV set have gotten the

approval of safety authentication inspection. The replacement CRT should be exactly the same type and

specification CRT which has gotten a similar safety approval, and check the high voltage according to

the HIGH VOLTAGE CHECK procedure.

1.2 safety precaution

a. Since the power supply circuit of this receiver is directly connected to the AC power line, an isolation

transformer is necessary during dynamic service to avoid possible shock hazard.

b. Always discharge the graphite layer conductor when moving the CRT.

c. Disconnect the power cord before replacing parts.

d. When replacing high-power resistor, keep the resistor 10 mm away from the circuit board.

1.3 Component safety precaution

Many electrical and mechanical parts in the chassis have special safety-related characteristics. These

characteristics are often passed unnoticed by a visual inspection. Replacement parts which have these

special safety characteristics are identified in this manual and its supplement electrical components

having such features are shaded or marked by on the schematic diagram and the parts list. Before

replacing any of these components, read the parts list in this manual carefully. The use of substitute

replacement parts which do not have the same characteristic as specified in the parts list may create

shock, fire, X-RAY RADIATION or other hazards.

2.General instruction

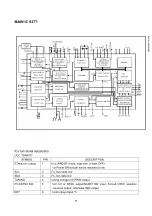

2.1 Copy the standard model data to let EEPROM of the chassis have those data before placing it on the

unit, do “factory adjustment” if necessary. If use a blank EEPROM directly, you should preset IIC data

and then do other common adjustment. Refer to TABLE1 to preset EEPROM.

2.2 the adjustment should be done under following circumstances without additional instruction

a) Alternating current 120V/60Hz

b) Preheat at least 30 min

2.3The unit has auto degaussing circuit, the auto degaussing process can be finished within 1s when the

main power. only when turn on the unit at least 30min after last time turn off TV does the auto

degaussing circuit work.

2.4 If the CRT with magnetism affects color purity and convergence, when the auto degaussing

eraser. if the color purity and convergence are still not very good, then corresponding adjustment

should be done. Refer to picture tube adjustment method for adjustment.

3

Alignment instruction

Note: This service manual is only for professional service personnel’s reference. Before

servicing the unit, please read the following items carefully.