5 Installation

5.1 General information

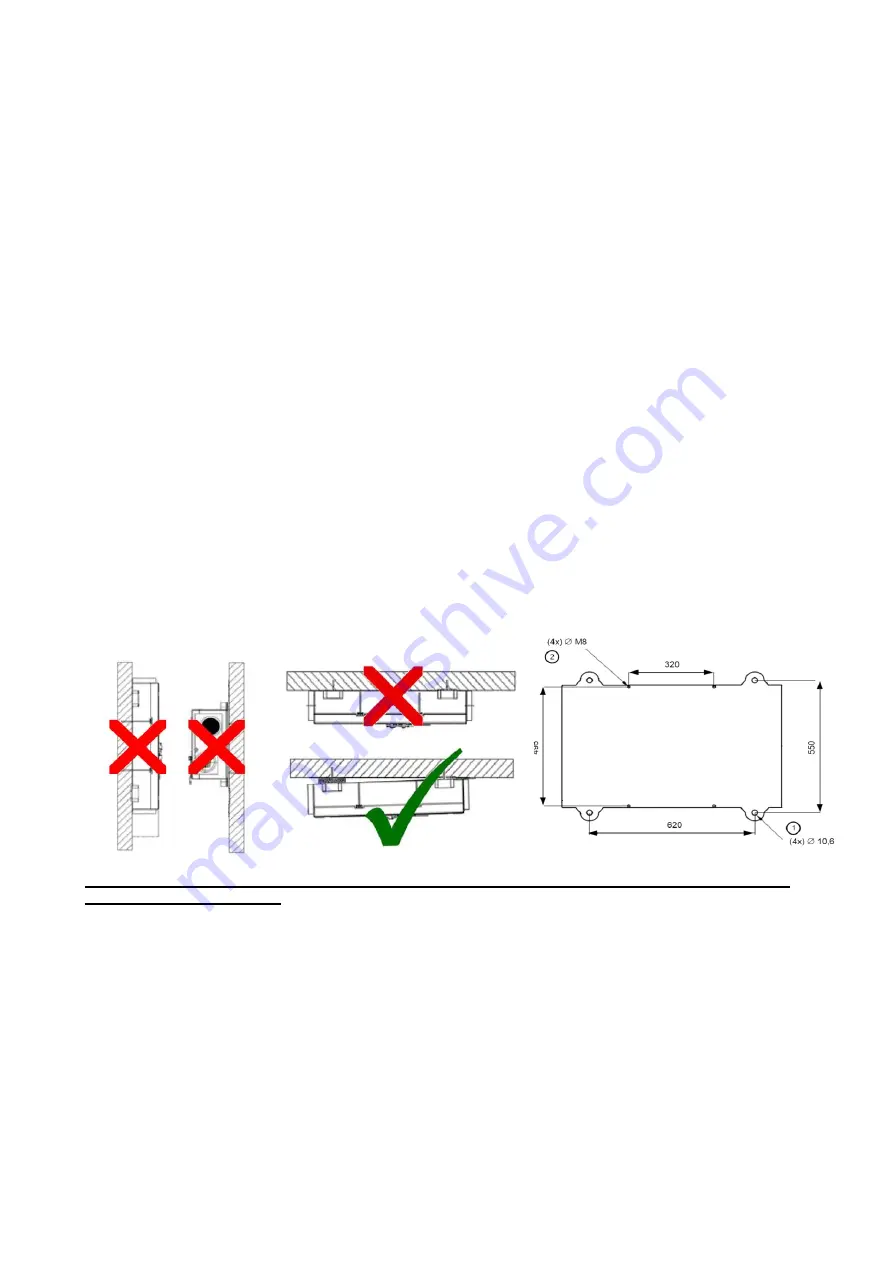

The MVHR unit should be mounted slightly tilted from the horizontal to ensure effective condensate drain-

age.

If mounting on plaster board use the following fixing method:

Use 15 mm nominal plywood backing board to connect directly to the internal ceiling studwork and

then mount the MVHR unit on the plywood

Ensure internal thermal or sound insulation is installed inside the stud wall to prevent reverberation

The MVHR unit may only be installed in dry, non-explosion proof rooms (protection category IPX2).

The ambient temperature must not 40°C.

This MVHR must not be fitted in rooms or areas of the house with strong odours, which could then permeate

into the MVHR and contaminate the fresh air supplied from the MVHR unit.

The following must also be met:

Access is required for maintenance work (e.g. changing the filter)

The condensate drain must be connected to a closed water trap and must have a sufficient gap

( Approx. 50cm is ideal)

If the condensate drain is located in a frost prone area, then heat tracing must be provided.

5.2 Ceiling mounting the MVHR

A spacer bar is provided which is placed between the unit and the fixing surface to provide a fall to

the condensate drain outlet

There are to fixing methods provided for direct bolting or treaded down rods.

Mark out the fixing holes mounting brackets using the diagram shown in section 5.3.1 and drill the holes

to suit the fixing bolts or anchors to be used

Fix the unit using suitable locking bolts and washers

5