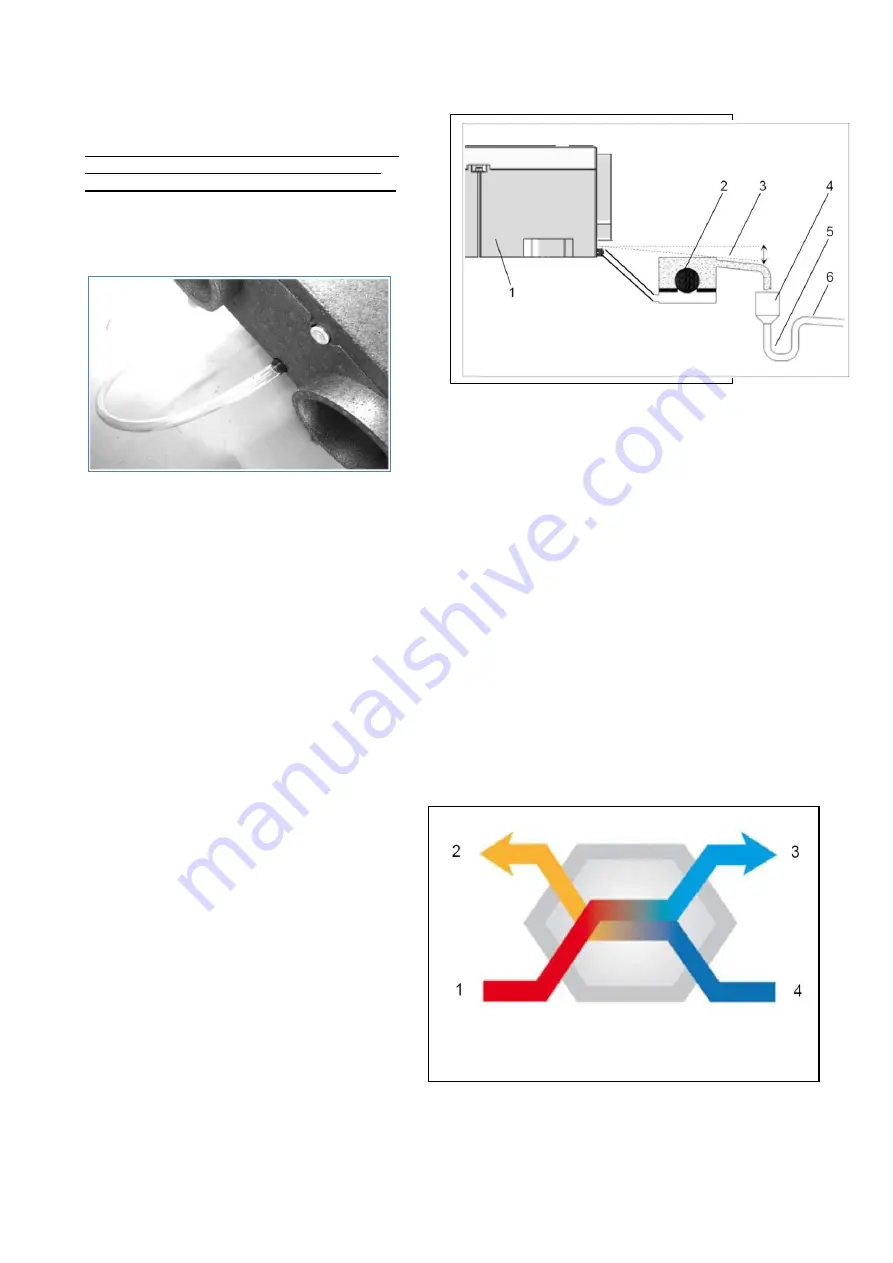

5.4 Condensate drain

Ensure that the spacer bar provided is fitted

between the unit and the fixing surface to

provide a fall to the condensate drain outlet

A condensate drain must be fitted to run to the

building waste water system in accordance with

the Building Regulation H1.

There are two condensate outlets. Both have caps

fitted - remove the cap from the lower outlet.

The condensate drain tube is then connected to the

outlet on the end of the unit. The condensate drain

tube can be adapted to the installation requirement.

It is important that the condensate drain tube at the

unit is positioned higher than the water surface of

the water trap and that the condensate drain tube

ends within the water head of the water trap.

The condensate drain tube should be checked

annually and cleaned if necessary. A condensate

drain tube (

Ø

20mm and 1.0m long) is supplied.

The water trap must be purchased separately from

a local plumbing stockist.

5.5 Typical installation example

1. Exhaust air

from the Wet rooms

kitchen / bathroom / toilet

2. Supply air

into the building via

living rooms/ bedrooms

3. Exhaust air

(from inside to outside)

4. External air

(fresh air)

Heat is transferred from stale warm extracted air

to warm the incoming cool fresh air saving energy.

1.

Stratum MVHR ventilation unit

2.

Condensate hose (inclined)

3.

Siphon with dry running protection preventing

air filtration

4.

Funnel receiving water from the outlet

5.

Siphon preventing infiltration of sewer gases

6.

Drainage pipe (inclined)

NOTE:

Water trap must be prefilled with water after

completion.

NOTE:

Ensure that the condensation hose is suffi-

ciently inclined. Incorrect installation can cause

water damage.

NOTE:

The condensate hose must be checked and

cleaned regularly, at least annually.

.

7