Inside installation of the finisher ring

Proceed as follows:

i)

Push the large tube through the hole so it extends some 50mm beyond the face of the outside wall.

ii)

Apply silicon mastic around the rear face of the split finisher – do not compress the adhesive.

ENSURE EXTERIOR BRICKWORK IS DUST FREE

iii)

Grip the finisher in your right hand, (palm uppermost) at the left hand end of the split with the adhesive side

facing you and the split at the top. Pull back the right hand end of the split along your right arm with your left

hand. Push the finisher right through the large tube and let it expand again. Don’t let go !

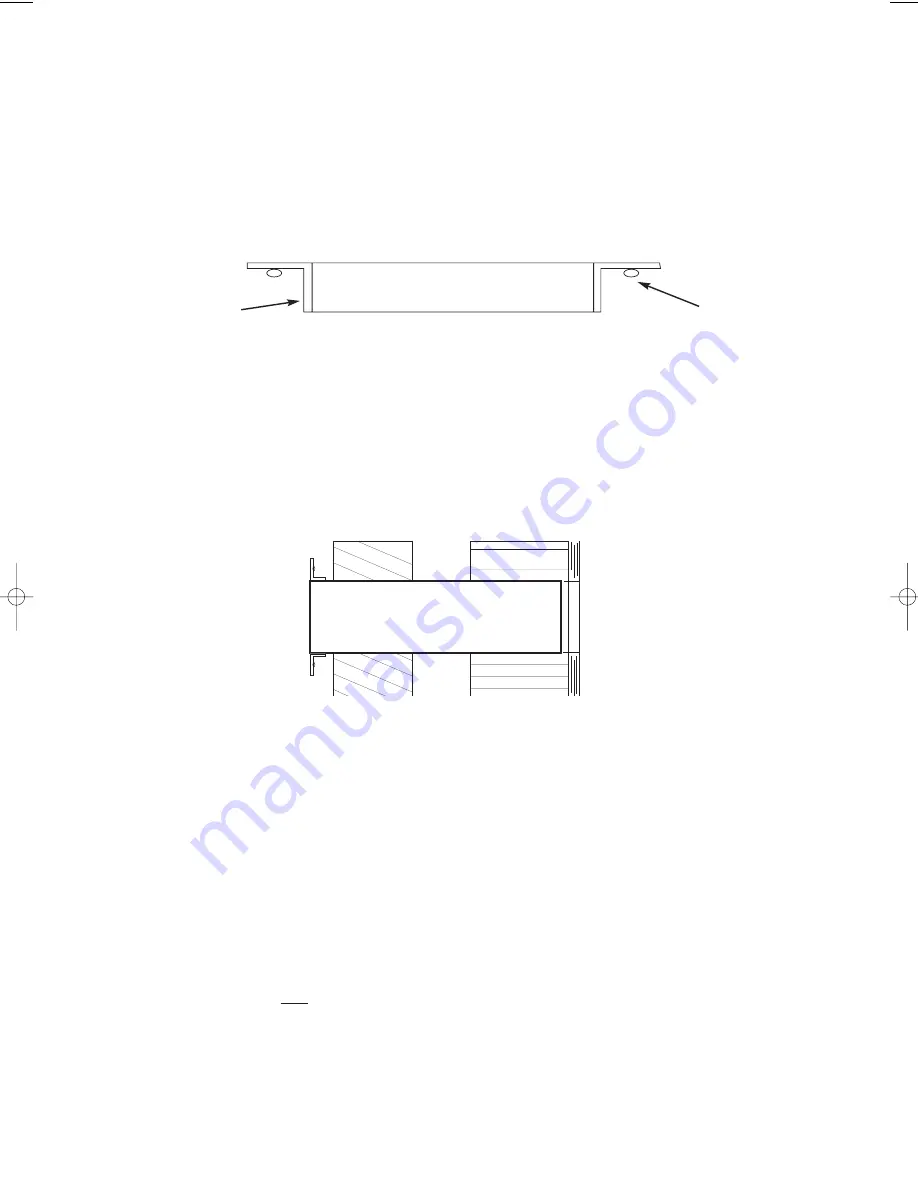

With your right hand, place the inner flange on the outside of the large tube. Move your fingers in an

anticlockwise direction until the finisher is pushed fully onto the tube (see below)

iv)

Then, pull the tube and finisher back towards the room making sure that the split remains at the bottom. Carefully

pull the finisher into the gap between tube and brickwork. Press the adhesive gently against the wall, compressing

the adhesive. Then pull the tube into the room leaving the finisher in place. Ensure that the finisher does not fall.

v)

Now manipulate the finisher to expand it outwards and increase it’s internal diameter as much as possible. This

will assist the re-entry of the tube. Compress the adhesive fully against the wall to hold it in position.

h)

Fit the outside cowl to your prepared length of tube using PVC adhesive such as

Bostik PVC Pipe Weld

or

similar. Place the adhesive in an even layer around the inside diameter of the tube at the end that you did not cut.

Place the outside louvred vent on the end of the tube and allow the glue to set before handling it again. Wipe off

any excess adhesive on the outside of the cowl.

i)

It is important for the correct operation that the smaller diameter tube is the correct length. This tube connects the

extraction fan housing to the outside cowl and separates the two air streams. The correct fitting of this tube is

critical to the efficient operation of the ventilator. To achieve this, whatever length has been cut off the outer tube,

the exact same length must be cut off the inner tube.

5

ADHESIVE

INNER FLANGE

Eclipse - Oxplaire 12/4/00 6:51 pm Page 5