https://www.XPOtool.com

Item 63027

Page 11

The Tool Experts

01 2022

-1

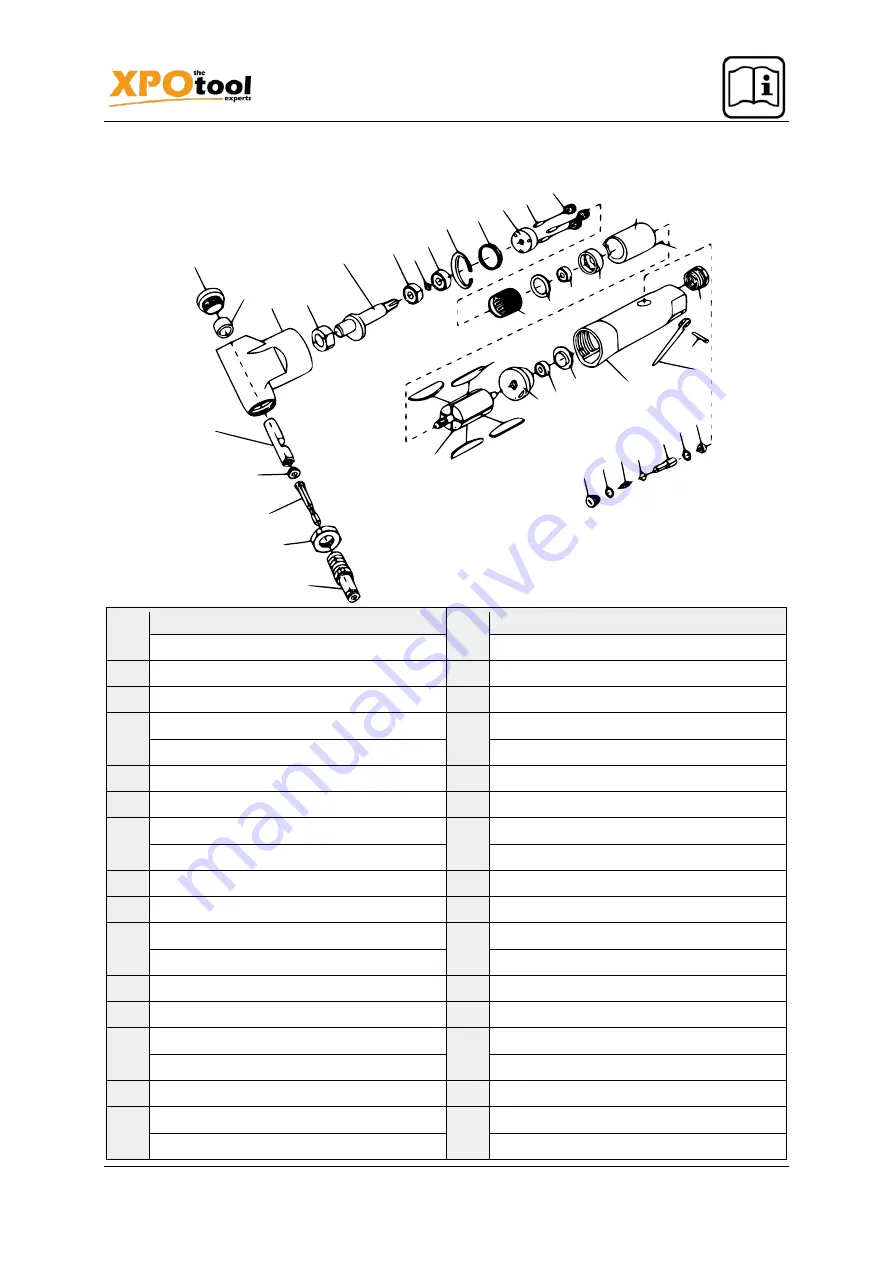

Exploded view and parts list

№

Name

№

Name

1

Air inlet bushing

21

Washer

2

Trigger lever

23

Gear case

3

Handle pin

24

Idler gear

4

Handle sleeve

25

Rear spindle

5

O-ring holder

26

Idler gear pin

6

O-ring

27

Nibbler head

7

Valve stem

28

Connecting rod bushing

8

Valve ball

29

Connecting rod

9

Spring

30

Cutter

10

Plug

31

Screw

11

O-ring

32

Die

12

Rear end plate

33

Nut

13

Bearing

34

Drive bushing

14

End plate cap

35

Shaft

15

Rotor

36

Bearing

16

Vane

37

Washer

17

Cylinder

39

Snap ring

18

Pin

40

Nut

19

Front end plate

41

Plug

20

Bearing