https://www.XPOtool.com

Item 63027

Page 5

The Tool Experts

01 2022

-1

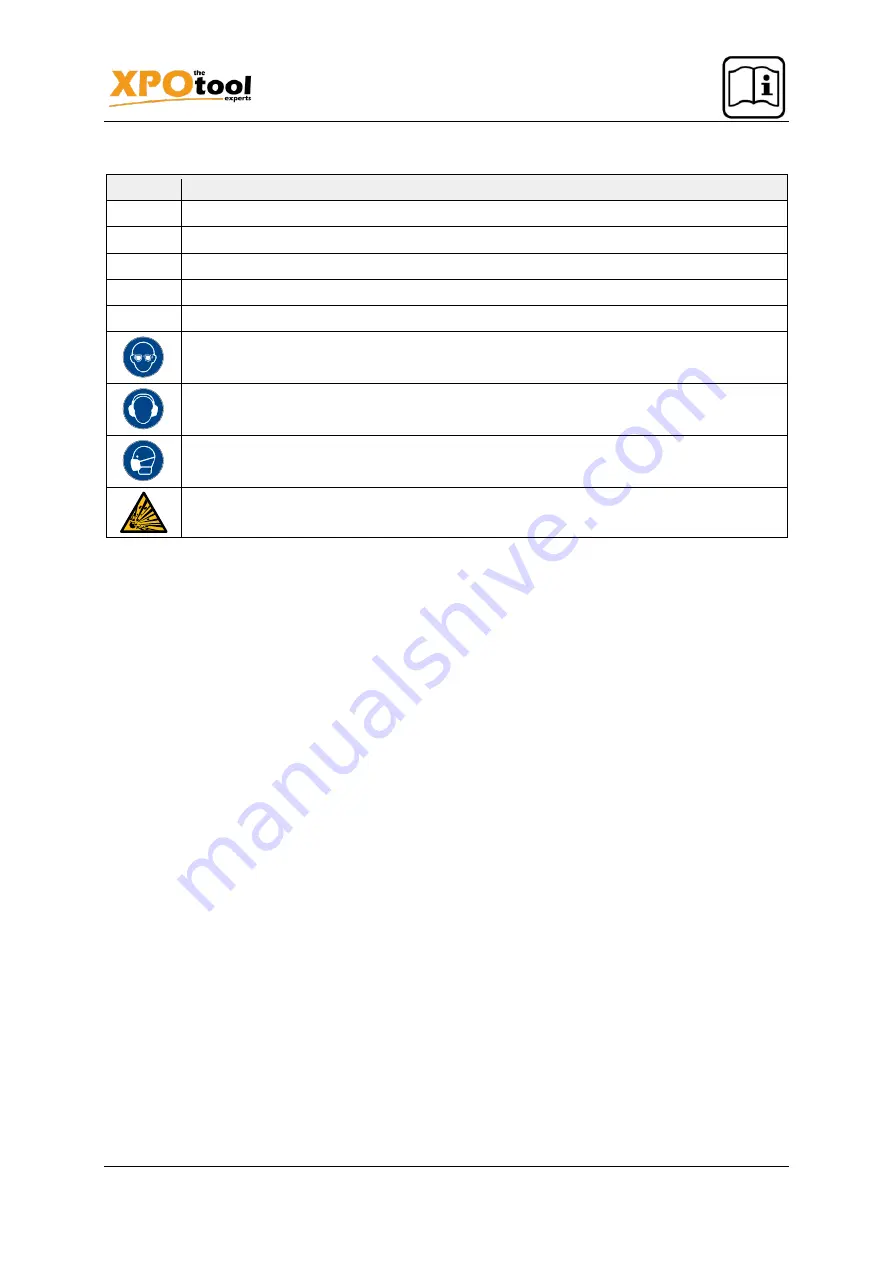

Symbols, units, and special safety instructions

Symbol

Meaning

psi

Pressure in pounds per square inch

bar

Pressure in bar

strokes

⁄

m

Strokes per minute (spm)

ft³

⁄

m

Flow in cubic feet per minute (cfm)

ℓ

⁄

min

Flow in litres per minute (lpm)

Warning regarding risk of eye injuries – wear approved safety glasses!

Warning regarding the risk of hearing loss – wear hearing protection!

Warning regarding respiratory dangers – wear an approved respiratory/dust mask!

Warning notice regarding risk of explosion

Special safety instructions

•

The warnings and safety precautions mentioned in this manual cannot cover all circumstances

and scenarios that may occur. The user must be aware that common sense and caution are

essential when using the tool.

•

Warning:

Certain dusts generated during grinding, sawing, sharpening, drilling work or similar

procedures contain chemical components known to be carcinogenic, to cause birth defects or

other reproductive harm. These are e.

g.

◦

lead from lead-containing paint,

◦

crystalline silica from bricks, cement, or other masonry materials,

◦

arsenic and chromium from chemically treated timber.

The risk depends on the frequency and duration of the exposure to these substances. To reduce

the associated hazards, always work in well-ventilated areas and wear approved safety equip-

ment, such as a respirator specifically designed to filter out microscopic components.

•

Warning:

The brass parts of this device contain lead which can cause birth defects and other

reproductive harm.

•

Always follow the instructions contained in the operating instructions for the compressed air

device that is used with the tool.

•

Mount an in-line shut-off valve with which you can regulate the air supply immediately in an

emergency, even in case of the compressed air hose tearing.

•

Always hold the tool with both hands during operation. Holding the tool with only one hand may

cause loss of control.

•

Do not put the tool down until it has come to a complete standstill. Rotating parts might otherwise

might contact with the surface and pull the tool out of your area of control.

Protection against vibrations

The tool vibrates during operation. Frequent or prolonged exposure to these vibrations can cause tem-

porary or permanent physical damage, especially to your hands, arms, and shoulders. To reduce the

damage caused by vibrations, please note the following:

•

Before a regular or long-term exposure to vibration, every person affected should first be exam-

ined by a doctor and then be examined regularly afterwards. This way, health problems caused

by using the tool might be prevented or already existing conditions might not be worsened.