https://www.XPOtool.com

Item 63027

Page 9

The Tool Experts

01 2022

-1

User-maintenance

Maintenance work that is not expressly explained in this manual should only be carried out

by a qualified technician.

Warning!

TO AVOID SERIOUS INJURY FROM UNINTENDED OPERATION: Switch the tool off, disconnect

it from the air supply, carefully release the compressed air remaining in the tool and release the

trigger and/or turn the switch to the “off” position before carrying out any kind of inspection,

maintenance, or cleaning work.

TO AVOID SERIOUS INJURY CAUSED BY MALFUNCTIONS OF THE TOOL: Do not use damaged

devices. If unusual noises or vibrations occur or if air escapes in the wrong places, have the

error rectified before further use.

TO AVOID SERIOUS INJURY FROM EXPLOSION: Only lubricate the tool with the spec-

ified lubricants. Only lubricate the air inlet with pneumatic tool oil. Only lubricate the

internal mechanism with white lithium grease. Other lubricants can damage the mech-

anism and be highly flammable, which can cause an explosion.

Cleaning, maintaining, lubricating the tool

Note:

The measures described here apply in addition to the regular checks and maintenance proce-

dures explained as part of normal operation of this compressed air tool.

1.

Daily – air supply maintenance:

Maintain the air supply every day according to the manufacturer’s instructions. Check the oil

level in the lubricator and top up with lubricant if necessary. Empty the moisture filter regularly.

Routine maintenance of the air supply will make the tool safer to operate and reduce wear and

tear.

2.

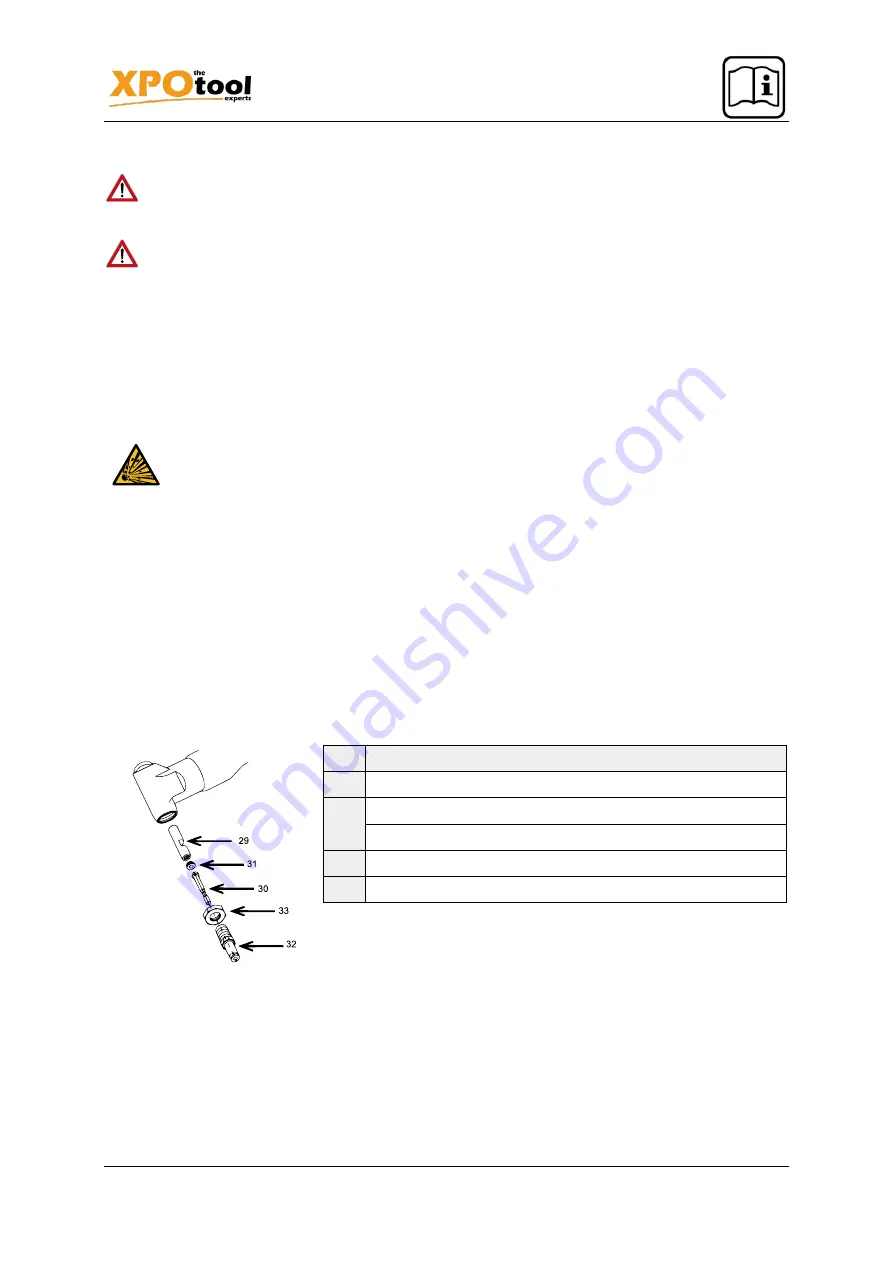

Regularly check the condition of the cutting knife

(30).

If it is dull or damaged, it must be re-

placed. Exchange as follows:

№

Name

29

Connecting rod

30

Cutter

31

Screw

32

Die

33

Nut

a)

Unscrew and remove the die

(32),

nut

(33)

and screw

(31).

b)

Pull the cutter out of the connecting rod

(29).

c)

Insert the new cutter and make sure that the tip of the cutting edge fits exactly into the

connecting rod.

d)

Reverse the above steps to reassemble the sheet metal nibbler.

3.

Trimestrial (every 3 months) – disassembling, cleaning, and checking of tool:

Have a qualified technician clean, inspect, and lubricate the inner mechanism. If the vanes need

to be replaced, replace them all.