https://www.XPOtool.com

Item 63080, 63081

Page 5

The Tool Experts

01 2022

-1

Maintenance

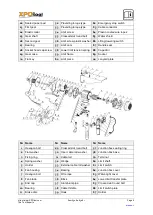

If your cable looks like

this, have it replaced in a

specialist workshop.

•

REGULARLY

check that the steel cable is in good condition.

•

REGULARLY

check the tight fit of the retaining screws of the

clamps and the reduction gear.

•

REGULARLY

check the condition and tightness of the screw nuts

for the clamps of the steel cable.

•

REGULARLY

check the circuit breaker and switch of the motor for

proper function.

•

Check the cable winch

REGULARLY,

at least once a year, for wear.

•

All moving parts must be well lubricated or oiled: hooks, drum axis, gears, and shafts, etc.

However, the steel cable must not be lubricated!

•

NOTE:

Hook wear: Check the hook for wear or abrasion losses during every maintenance. If

the wear exceeds 10

% of its dimension on delivery, it must be replaced.

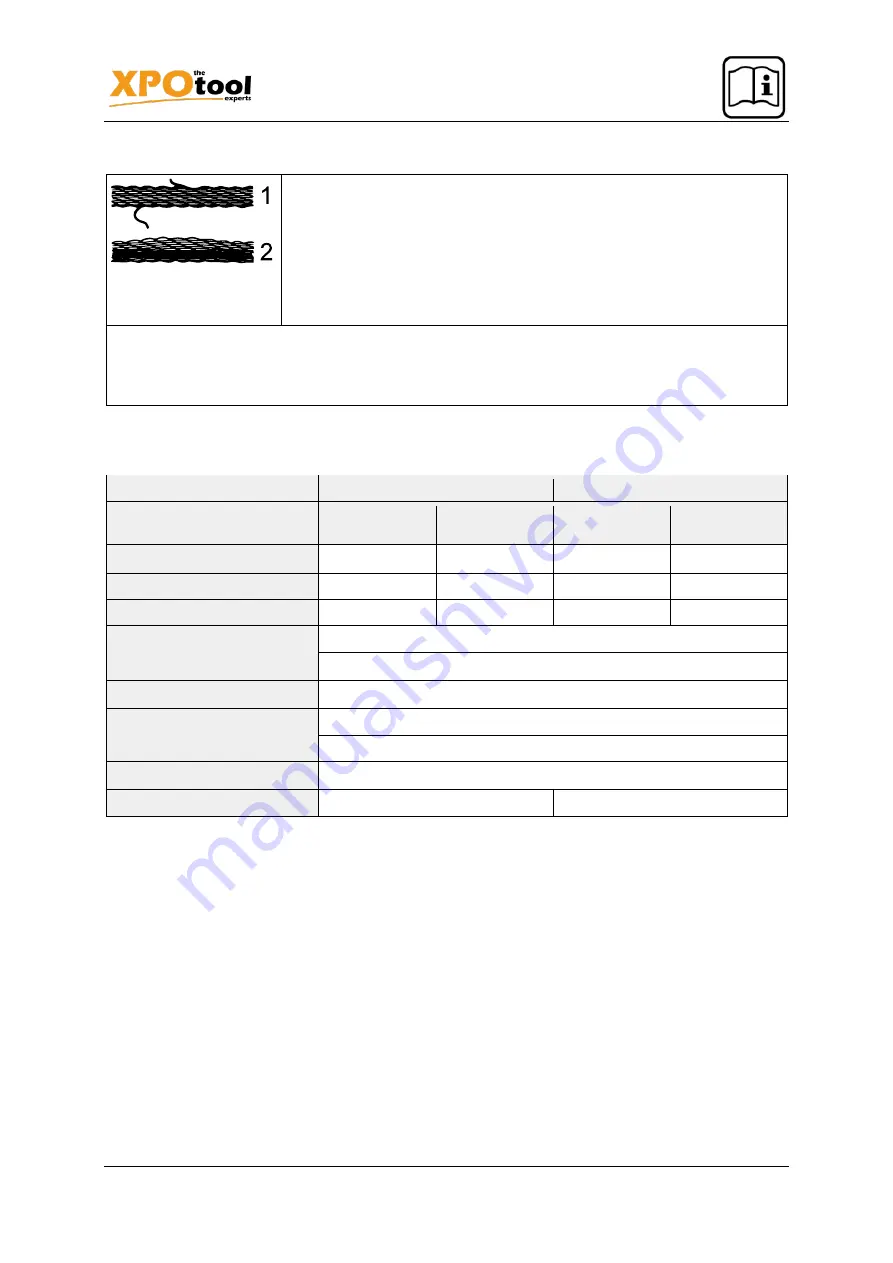

Technical data

Item number

63080

63081

Version

Standard

Double load

capacity

Standard

Double load

capacity

Load capacity

(

㎏

)

100

200

125

250

Max. lifting height

(m)

12

6

12

6

Lifting speed

(

m

⁄

min

)

10

5

10

5

Cable length

(m)

12.5

Cable diameter

(

㎜

)

3

Cable break resistance

(

㎏

)

≥800

Service

S3 – 20

% 10

min

Voltage

(V)

230

Frequency

(

㎐

)

50

Motor power P

1

(W)

480

540