https://www.XPOtool.com

Item 63368

Page 10

The Tool Experts

06 2022-1

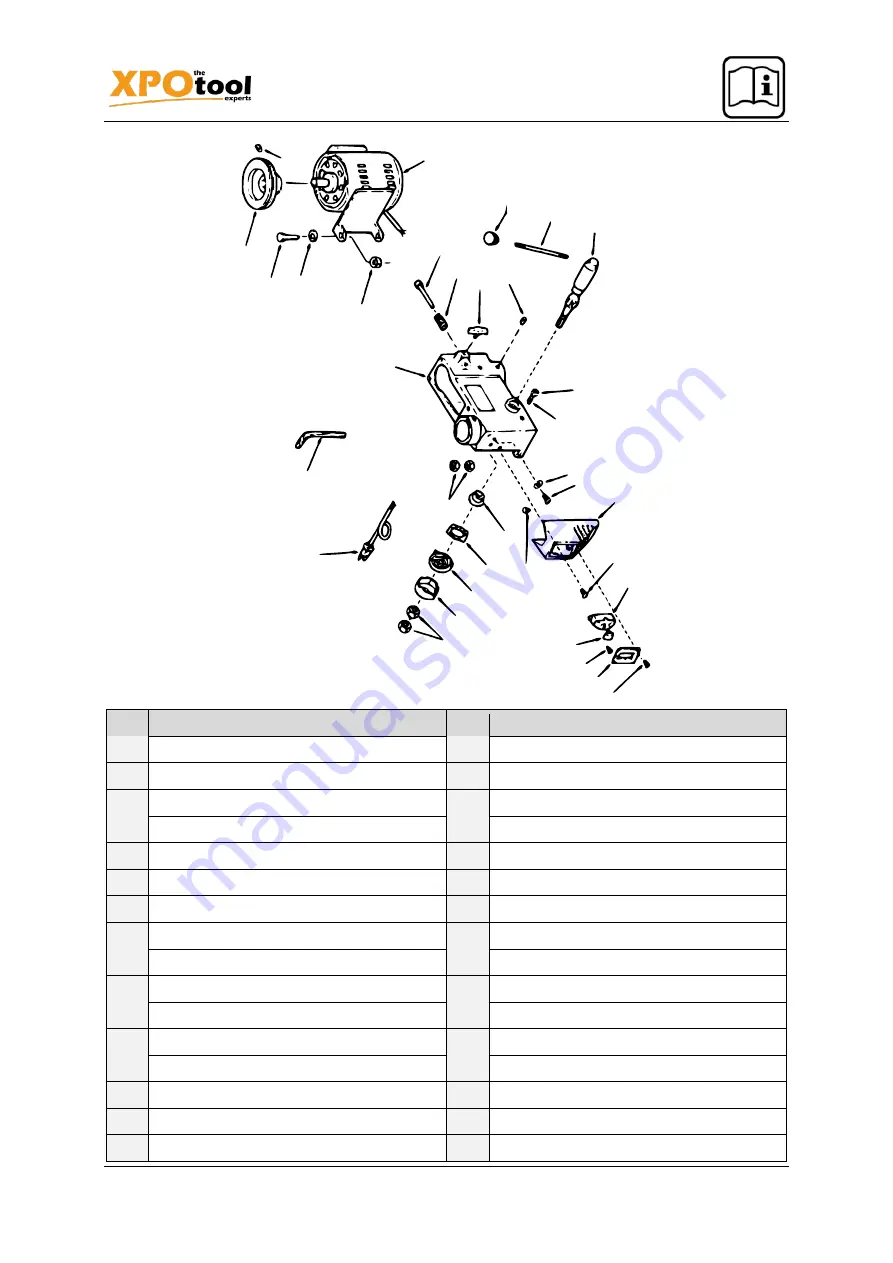

№

Name

№

Name

1

Head with pin and cover

17

Lock washer 5

mm

2

Locking nut M8×1.25–8

18

Screw M8×1.25

3

Washer

⅚

×

11

⁄

16

×

1

⁄

16

19

Switch box with depth scale

4

Hexagonal head screw M8×1,25–25

20

Screw M5×0,5–12

5

Motor pulley

21

Locking switch

6

Hexagonal head screw M6×1,0–10

22

Self-tapping screw

7

Motor

23

Switch cover

8

Motor stop

24

Main switch

9

Motor stop spring

25

Wire connection

10

Motor setting knob

26

Spring seat

11

Hexagonal head screw M8×1,25–8

27

Spring retainer

12

Knob

28

Tension spring

13

Bar

29

Spring cover

14

Pinion shaft

30

Hexagon head nut

15

Hex bolt M8×1.25

31

Power cable

16

Screw M8×1.25

32

Set-up key