https://www.XPOtool.com

Item 63368

Page 5

The Tool Experts

06 2022-1

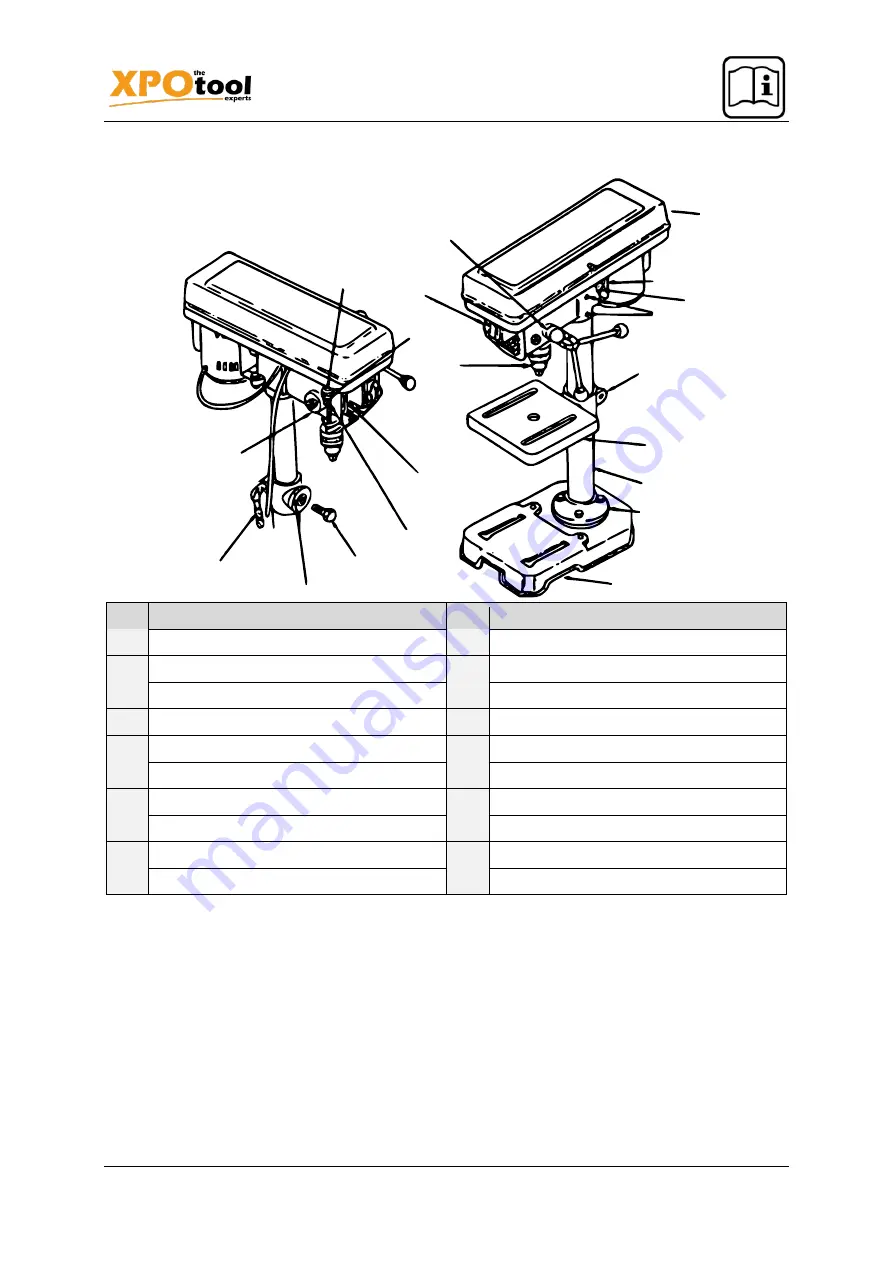

Components

№

Name

№

Name

1

Pulley guard cover

11

Column

2

Belt tension lock knob

12

Bevel scale

3

Locking screws

13

Table locking screws

4

Table support

14

Table

5

Column support

15

Feed handles

6

Support lock

16

Chuck

7

Foot

17

Feed stop rod

8

Spring cover

18

Stop nuts

9

Depth-scale indicator

19

Switch

10

Depth-scale

20

Motor stop

Use and maintenance

1.

It is essential that the operator reads this manual carefully before using the machine in order to

become familiar with the structure, controls and drive system of the machine.

2.

All ball bearings have been greased at the factory. No further lubrication is required. Lubricate

the grooves in the spindle and the rack (teeth) on a regular basis.

3.

Insert the drill bit into the chuck until it is fully secured in the jaws. Make sure that the drill bit is

positioned in the centre of the drill chuck. Tighten the drill bit properly to prevent it from slipping

during drilling. Turn the chuck key clockwise to tighten the drill bit, turn it anticlockwise to loosen

it.

4.

The drill depth can be adjusted either with the help of the pointer and depth scale or with the

stop nuts on the feed stop rod.