34

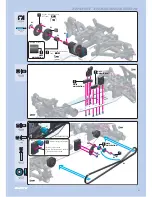

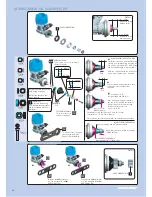

SHOCK ABSORBERS

TECH TIP

➊

➋

➌

➍

Follow this tech tip to properly install pivot balls

into the top pivot and bottom ball joint.

Parts Needed:

• M3 x 16 SH screw

• M3 shim

Note that the composite parts have two sides,

noticeable around the pivot ball hole: one side

has a shiny fi nish, the other side has a regular

fi nish.

Install pivot balls into top pivot or

lower ball joint as shown, on the

proper sides.

Note that the lower pivot ball has

an extra shoulder.

Remove screw and shim

SHINY

FINISH SIDE

Ensure pivot balls move freely

SHINY

FINISH SIDE

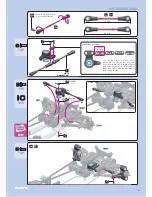

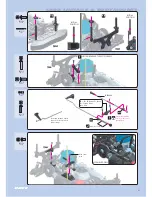

After the shock is assembled you have to set the Shock Rebound.

1. To set the Shock Rebound, release the shock composite lower cap.

2. VERY SLOWLY do the following: Fully pull out the shock rod, push it back in fully, and then fully pull

it out once more. Repeat this procedure the following number of times to achieve the desired Shock

Rebound setting:

10 times - approximately 75% rebound (high rebound - suggested for very low traction track)

15 times - approximately 50% rebound (medium rebound - suggested for standard track)

20 times - approximately 25% rebound (low rebound - suggested for very high traction track)

During the Rebound Adjustment procedure shock oil will leak out of the shock body through the O-ring

on the shock rod... this is normal. During the Rebound Adjustment procedure DO NOT open the upper

shock cap.

Cutaway view of

assembled shock absorber

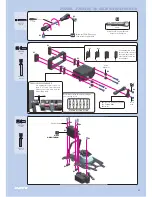

HARDEST

SOFTEST

1

2

3

4

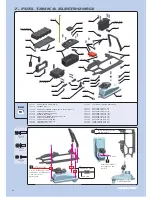

FRONT SHOCKS

(SHORTER SPRINGS)

CHECK NEXT

TECH TIP

REAR SHOCKS

(LONGER SPRINGS)

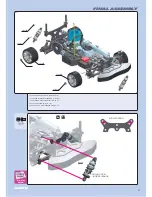

Shock length adjustment:

It is VERY important that all shocks are equal length.

Fully extend the shock absorber and measure the end-to-end

length; we recommend using digital calipers to give an accurate

measurement. If a shock absorber is shorter or longer than others,

adjust the shock length by tightening or loosening the ball joint on

the shock rod.

Damping adjustment:

If you built the adjustable shocks, fully extend the shock rod and turn it

slightly to lock the piston in the shock body.

Turning the shock rod fully CCW aligns 4 holes in the pistons (softest

damping). Turning the shock rod fully CW aligns 1 hole in the

pistons (hardest damping). The shocks have four settings, each of

which can be felt by a slight "click".

Set all four shocks initially to position 3 (3 holes open): turn fully

CCW, then turn CW by 1 click.

RELEASE

TIGHTEN

3. After you have set the Rebound Adjustment, re-install the shock lower composite cap.

4. Check the Shock Rebound setting by pushing the shock rod fully into the shock body, releasing it, and

observing how far the shock rod extends by itself:

* 25% out of the shock body (low rebound)

* 50% out of the shock body (medium rebound)

* 75% out of the shock body (high rebound).

If the shock rod rebounds too much, return to Step 1 and repeat the procedure.

If the shock rod does not rebound enough, you will have to refill the shock with shock oil, and then repeat

the bleeding and Shock Rebound procedure.

0%

50%

REBOUND

75%

REBOUND ADJUSTMENT

REBOUND CHECK

➊

➋

➌

➊

➋

SHOCK DAMPING

ADJUSTMENT

SPRING RATE SELECTION

Tighten screw until pivot ball

snaps into place

SHINY

FINISH SIDE

SHINY

FINISH SIDE

100%

25%

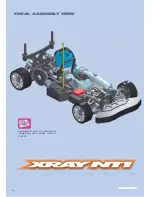

Summary of Contents for NT1

Page 1: ......