15

303240

308310

308070

308071

308393~308398

308040

309317

308360

309413

309412

308035

NON-ADJUSTABLE

308072

308310

308310

308080

308350

308310

308310

308035

ADJUSTABLE

4 HOLES

1-4 HOLES

OR

OR

OR

3 HOLES

2 HOLES

308320

OPTION

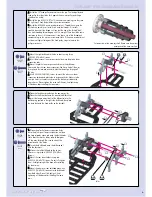

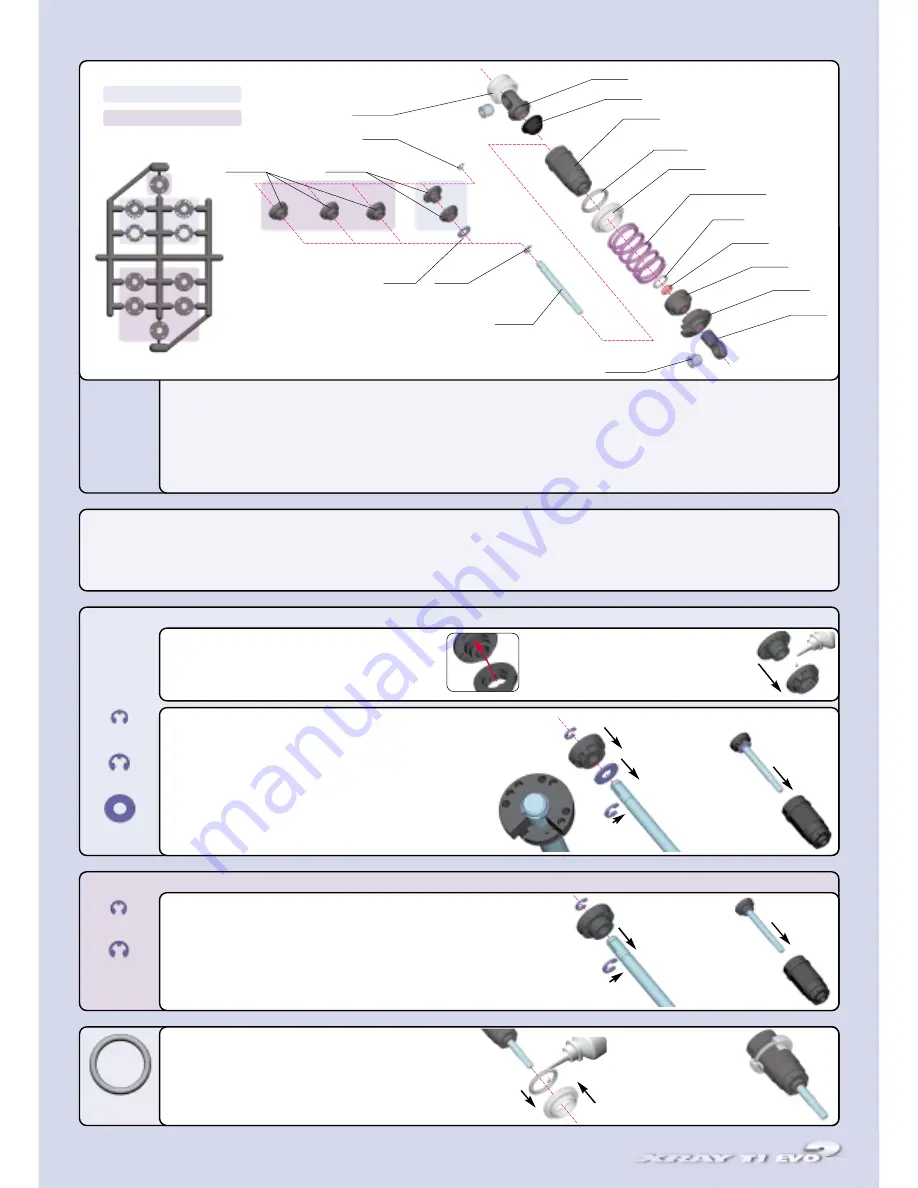

Properly functioning shocks are one of the most important factors in the performance of your car. This XRAY shock set allows you to build four externally-adjustable or non-

adjustable shocks. Both adjustable and non-adjustable shocks feature XRAY's unique keying system that positively locks the pistons to the shockrods.

When removing the parts from the frames, carefully remove the parts, then VERY carefully trim any excess flash with a sharp knife. We advise using extra-fine sandpaper to

gently grind all small flashes. The side walls of the pistons must be perfectly round and smooth for proper operation.

Assemble all four adjustable piston assemblies and shock rods as

follows:

1

1.. Press #309413 (C 2.3) E-clip into lower groove of shock rod.

2

2.. Place #309317 (S 3.2) washer onto shock rod atop C-clip.

3

3.. Press piston assembly onto shock rod, aligning flat in pistons

with flat on shock rod.

4

4.. Press #309412 (C 1.9) E-clip into upper groove of shock rod.

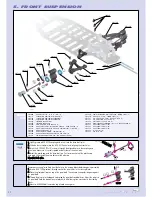

30 3240

BALL UNIVERSAL 5.8 MM HEX (4+4)

30 8040

SHOCK ADJ. NUT ALU + O-RING (4+4)

30 8070

O-RING / SHIM + C CLIPS (4+12)

30 8071

O-RING 5x1 (4)

30 8072

O-RING 12.1 x 1.6 (4)

30 8080

SHOCKABSORBER MEMBRANES (4)

30 8035

NYLON PISTONS ADJU NON-ADJUST. (SET 2+6)

30 8310

NYLON FRAME SHOCK PARTS 4-STEP

30 8320

ALU SHOCK-BODY TEFLON (4) (OPTION)

30 8350

SHOCK CAP NUT ALU

30 8360

HARDENED PISTON RODS FOR KEYED PISTONS (2)

30 8393

XRAY SPRING-SET D=1.3 YELLOW - SUPER-SOFT (OPTION)

30 8394

XRAY SPRING-SET D=1.4 WHITE - SOFT (OPTION)

30 8395

XRAY SPRING-SET D=1.5 BLUE - SOFT-MEDIUM (OPTION)

30 8396

XRAY SPRING-SET D=1.6 VIOLET - MEDIUM (OPTION)

30 8397

XRAY SPRING-SET D=1.7 PURPLE - MEDIUM-HARD (OPTION)

30 8398

XRAY SPRING-SET D=1.8 RED - HARD (OPTION)

30 9412

E-CLIP 2 (10)

30 9413

E-CLIP 3 (10)

30 9317

WASHER 3.2 (10)

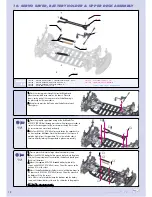

7. SHOCK ABSORBERS

Cutaway view of

assembled adjustment collar

➊

➋

➌

➍

Perform for all four shock bodies:

1

1..

Apply a drop or two of shock oil to the inside edge of the #308072

(O12.1x1.6) O-ring and insert it inside the groove of a #308040

threaded shock adjustment collar.

2

2..

Thread the adjustment collar onto the shock body.

➊

➋

309412

C 1.9

309413

C 2.3

309317

S 3.2

309412

C 1.9

309413

C 2.3

BAG

07

Apply a drop or two of shock oil to the piston

pieces. Press upper piston (A) into lower piston

(B) as shown. Be sure to insert the upper piston

into the lower piston so the tab sits in the notch.

Cut all shock parts free from the parts trees, carefully trim

any excess flash, and lightly sand if necessary.

The upper piston with holes (A) has a small tab that must

exactly fit into one of the notches in lower piston (B).

A

B

Cutaway view of

the adjustable piston

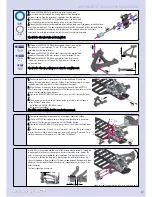

Cut all shock parts free from the parts trees, carefully trim any excess flash, and lightly

sand if necessary. Assemble all four non-adjustable piston assemblies and shock rods

as follows:

1

1..

Remove all four 3-hole non-adjustable pistons from the parts frames.

2

2..

Press #309413 ( C 2.3) E-clip into lower groove of shock rod.

3

3..

Press 3-hole piston onto shock rod, aligning flat in piston with flat on shock rod.

4

4..

Press #309412 (C 1.9) E-clip into upper groove of shock rod.

➊

➋

➌

Insert the shock

rod assemblies

into the shock

bodies.

Insert the shock

rod assemblies

into the shock

bodies.

ADJUSTABLE PISTONS

NON-ADJUSTABLE PISTONS

ADJUSTABLE PISTONS

NON-ADJUSTABLE PISTONS

308035

308072

O 12.1x1.6

Summary of Contents for T1 EVO2

Page 1: ......