1

The XRAY T1 EVO2 is arguably the most advanced 1/10-scale on-road electric

touring car ever made for racing and is based on the extremely successful XRAY

T1 concept. We have used the results of thousands of hours of racing and testing

on both of asphalt and carpet tracks to offer you this next step in the evolution of

XRAY T1.

You chose the T1 EVO2 because you recognize the outstanding quality of design,

craftsmanship, and performance of this touring car chassis. The XRAY T1 EVO2 is

the epitome of high-performance engineering that was built for the purpose of

top competition races. The design is focused on blending of extraordinary

materials with racecar lineage to offer a responsive ride, luxurious elegant

design, finest quality, and best track performance.

This car was built purely for top competition races, and for that purpose, we gave

the T1 EVO2 the highest number of adjustments possible to get the most

performance out of any track condition. Even with the standard setup, the T1

EVO2's handling is stable and predictable enough on most surfaces for even

novice drivers who choose the T1 EVO2 as their entrance into the R/C hobby.

Every aspect of the T1 was examined not only to make it the best touring car on

the market, but to also make it very easy to build, to work on, and to drive. This

instruction manual strengthens our philosophy of providing our customers with

only the best.

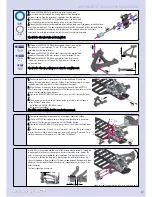

The assembly steps are illustrated with state-of-the-art rendered 3D models taken

from our engineers' graphics workstations, and supported with clear and easy-to-

understand descriptions of the assembly steps. Because suspension tuning can be

a difficult step, we have produced a special Set Up Book to help you get your car

to its maximum performance. In some of the assembly steps, references are

made to a particular section of the Set-Up Book. Measurements should be

applied immediately, although it will still be necessary to perform the set-up

procedures again for fine tuning once the chassis is finished.

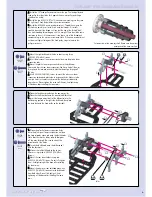

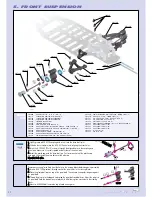

At the beginning of each section, there is an exploded view of the relevant

assembly, including the parts for that section. All non-relevant and previously

assembled parts have been faded. Each section indicates the bag containing all

the appropriate parts. All hardware (screws, nuts, bearings, pins, clips, etc.) can

be compared to the 1:1 scale diagrams on the left side of each assembly step.

There should no parts left over after you finish the given assembly section. If there

are any left, please go through the assembly steps again to ensure all parts have

been used properly.

We have made every effort to make the instructions and Set-Up Book as easy to

understand as possible. However, if you have any difficulties, problems, or

questions, please do not hesitate to contact the XRAY support team at

support@teamxray.com. Also, please visit our web site at www.teamxray.com.

Our official web site contains all the latest updates, hot setup information, lists of

hop-up parts, and many other goodies.

As the proud owner of an XRAY T1 EVO2, you are cordially invited to join TEAM

XRAY. Use the MEMBERSHIP CARD with Certificate of Authenticity to register your

T1 EVO2 at world's largest RC portal www.myTSN.com to get access to the

special XRAY VIP ROOM --- we pride ourselves on really taking care of our

customers.

Thank you very much for choosing the XRAY T1 EVO2 as your ultimate 1/10

electric touring car. We are sure it will bring you lots of enjoyment and rear

racing excitement.

CONTENTS

0.

KIT

1

1.

FRONT & REAR DIFFERENTIAL

2-3

2.

REAR TRANSMISSION

4-5

3.

REAR SUSPENSION

6-8

4.

FRONT TRANSMISSION

9

5.

FRONT SUSPENSION

10-11

6.

SERVO SAVER

12-13

7.

SHOCK ABSORBERS

14-15

8.

REAR FINAL ASSEMBLY

16

9.

FRONT FINAL ASSEMBLY

17

10.

SERVO SAVER, BATTERY HOLDER

& UPPER DECK ASSEMBLY

18

11.

ACCESSORY INSTALLATION

19-20

CONGRATULATIONS

IIn

n lliin

ne

e w

wiitth

h o

ou

urr p

po

olliiccyy o

off cco

on

nttiin

nu

uo

ou

uss p

prro

od

du

ucctt d

de

evve

ello

op

pm

me

en

ntt,, tth

he

e e

exxa

acctt ssp

pe

ecciiffiicca

attiio

on

nss o

off tth

he

e k

kiitt m

ma

ayy vva

arryy.. IIn

n tth

he

e u

un

nlliik

ke

ellyy e

evve

en

ntt

o

off a

an

nyy p

prro

ob

blle

em

mss w

wiitth

h yyo

ou

urr n

ne

ew

w k

kiitt,, yyo

ou

u ssh

ho

ou

ulld

d cco

on

ntta

acctt tth

he

e m

mo

od

de

ell ssh

ho

op

p w

we

erre

e yyo

ou

u p

pu

urrcch

ha

asse

ed

d iitt,, q

qu

uo

ottiin

ng

g tth

he

e p

pa

arrtt n

nu

um

mb

be

err..

W

We

e d

do

o rre

esse

errvve

e a

allll rriig

gh

httss tto

o cch

ha

an

ng

ge

e a

an

nyy ssp

pe

ecciiffiicca

attiio

on

n w

wiitth

ho

ou

utt p

prriio

orr n

no

ottiicce

e.. A

Allll rriig

gh

httss rre

esse

errvve

ed

d..

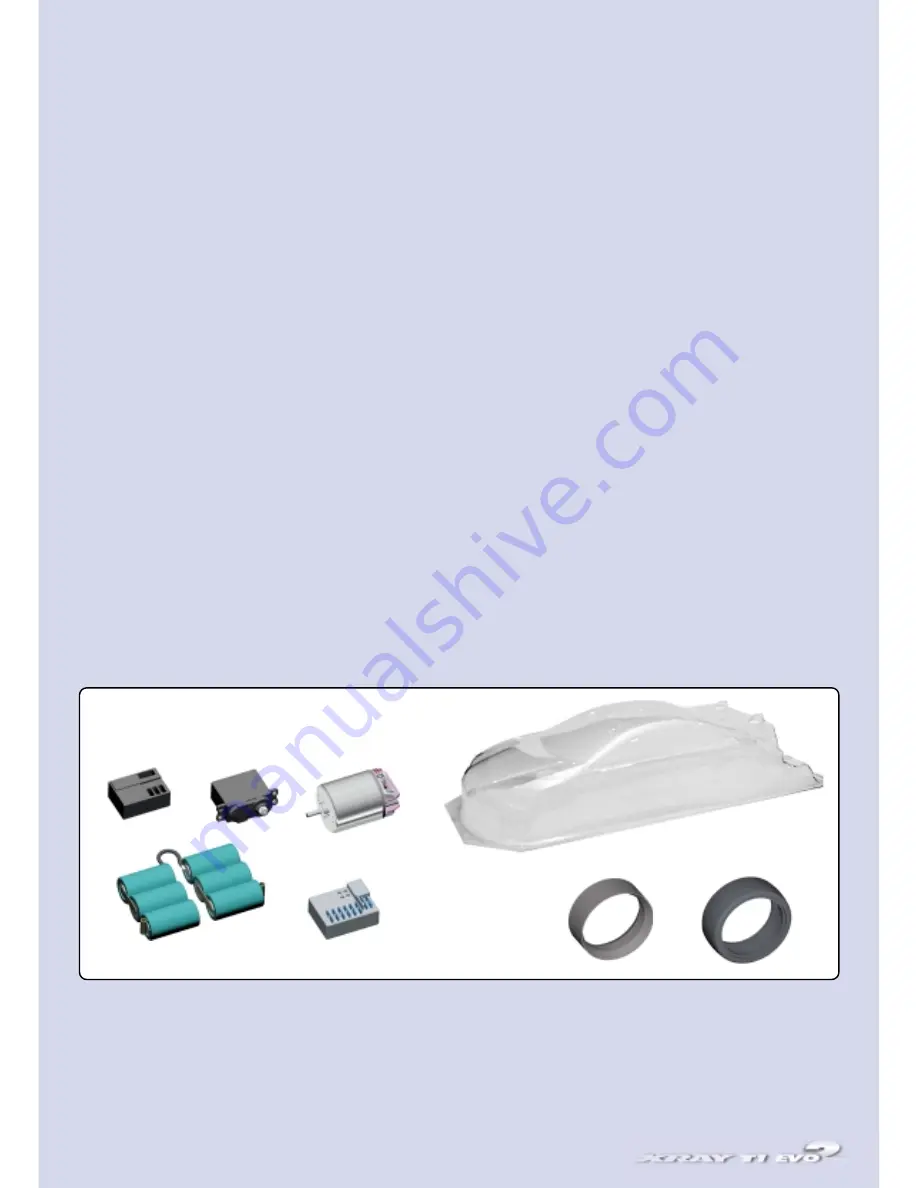

ADDITIONAL ITEMS REQUIRED:

TOOLS REQUIRED:

Cutting Pliers, Needlenose Pliers, Snap Ring Pliers, Allen Wrench for Set Screws 1.5 mm, 2.0 mm, 2.5 mm, 3.0 mm and 5.0mm, Hobby Knife, Caster Clip Remover Tool,

Soldering Iron.

For the most comfortable assembly we advise to purchase these HUDY high-quality tools: #111540, #112040, #112540, #113040, #115040, #107610.

Radio system (transmitter and receiver), steering servo, motor, battery pack (6-cell), speed

controller, charger, 1/10-scale bodyshell (190 mm), tires, inserts, double-sided tape, CA

glue, bearing oil.

Summary of Contents for T1 EVO2

Page 1: ......