3

8.0 mm

3.2 mm

7.8 mm

3.0 mm

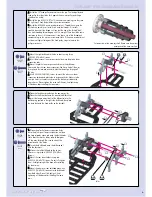

1.FRONT & REAR DIFFERENTIAL

305050

305020

309020

305082

305090

305050

305082

309442

309370

309070

305040

305010

305050

30 5010

ALU DIFF LONG OUTPUT SHAFT HARD COATED

30 5020

ALU DIFF SHORT OUTPUT SHAFT HARD COATED

30 5040

SCREW FOR EXTERNAL DIFF ADJUSTMENT - SPRING STEEL

30 5050

DIFF PULLEY 34T WITH LABYRINTH DUST COVERS

30 5082

DIFF WASHER 17x23x1 (2)

30 5090

BALL STEEL 2.4 MM (24)

30 9020

BALL-BEARING MR85ZZ 5x8x2.5 (2)

30 9070

BALL-BEARING AXIAL F3-8 3x8x3.5

30 9442

CH-CLIP 8 (10)

30 9370

CONE WASHER 3 x 8 x 0.5 (10)

PPlleeaassee nnoottee tthhaatt pprrooppeerrllyy ffuunnccttiioonniinngg ddiiffffeerreennttiiaallss aarree eexxttrreem

meellyy iim

mppoorrttaanntt ttoo tthhee ppeerrffoorrm

maannccee ooff tthhee ccaarr.. TThheerreeffoorree,, iitt iiss iim

mppeerraattiivvee tthhaatt yyoouu m

maakkee

ssuurree tthhaatt tthhee ddiiffffeerreennttiiaallss m

moovvee ffrreeeellyy aafftteerr aasssseem

mbbllyy oorr rreebbuuiillddiinngg,, aanndd aafftteerr eevveerryy rruunn.. FFoorr ddiiffffeerreennttiiaall aaddjjuussttm

meenntt,, pplleeaassee rreeffeerr ttoo tthhee SSeett--uupp BBooookk..

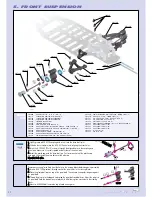

1

1..

The diff locknut is pre-installed in the short diff output shaft. If you

need to replace the diff locknut, push it out from the opposite side

with the tip of a wrench. Insert a new one into the short diff shaft.

2

2..

Place one #309020 (BB 5x8) ball-bearing on the short center stub

of the diff shaft.

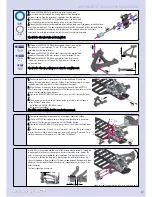

3

3..

Put a very thin coat of grease on the side of a diff washer, and

place it on the diff shaft. The washer should seat centered on the diff

shaft, and the layer of grease will hold it in place.

4

4..

Press the diff pulley onto the ball bearing.

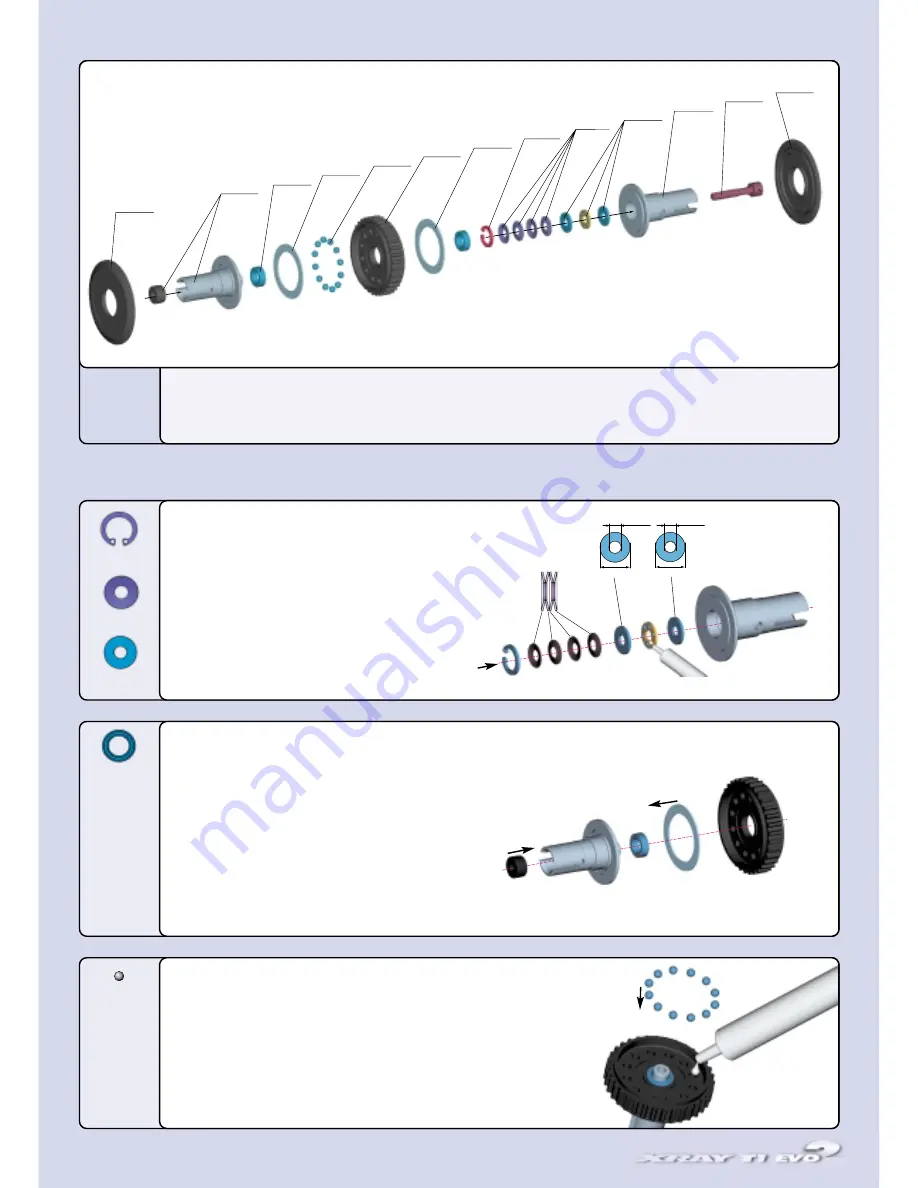

1

1..

Apply a little bit of grease into each of the 12 holes in the diff pulley.

2

2..

Place the 12 balls in the diff pulley holes.

The long diff output shaft is preassembled at the factory. When it

comes time to clean or rebuild the diff, please follow these steps:

1

1..

Insert the smaller of the two thrust washers into the long diff shaft

as shown in the diagram above.

2

2..

Apply a little grease to the balls in the caged thrust ball holder.

Coat each side with grease. Insert the thrust ball cage into the long

diff shaft.

3

3..

Place the larger thrust washer in the diff shaft.

4

4..

Insert the four cone washers according to the detail shown above.

5

5..

Secure the assembly with the #309442 (C 8) clip. There is a

groove inside the diff shaft for the clip to seat into.

Note: Assembly will be easier with snap-ring pliers.

FACTORY PREASSEMBLED

➊

➋

➌

➍

➎

➊

➋

➌

➍

➊

➋

BAG

01

G

GR

REE

A

ASS

EE

309442

C 8

309370

ST 3x8

309070

BA 3x8

309020

BB 5x8

305090

B 2.4

G

G

RREE

A

ASS

EE

FACTORY PREASSEMBLED

Summary of Contents for T1 EVO2

Page 1: ......