5

30 2040

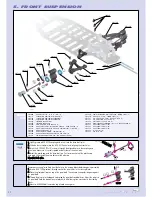

LOWER SUSPENSION HOLDER (SET 2+1+1)

30 2070

ECCENTRIC NYLON HUB FOR BULKHEAD + COVERS (4+2)

30 2053

ALU LOWER SUSPENSION HOLDER

30 3040

ALU REAR BULKHEAD BRACE

30 5001

BALL DIFFERENTIAL - SPRING STEEL - SET (OPTION)

30 5431

HIGH-PERFORMANCE KEVLAR DRIVE BELT FRONT 3 x 507 MM

30 5441

HIGH-PERFORMANCE KEVLAR DRIVE BELT REAR 4 x180 MM

30 5511

LAYSHAFT SPRING STEEL INTEGR. SPUR G. ADAPTER EVO2

30 5540

ONE-WAY ADJUSTMENT NUT M6

30 5570

FIXED PULLEY 16T

30 5582

ONE-WAY PULLEY 16T WITH GROOVED ONE-WAY BEARING

30 9035

HIGH-SPEED BALL-BEARING MR95ZZ 5 x 9 x 3 BLUE COVERED (2)

30 9045

HIGH-SPEED BALL-BEARING MR106ZZ 6 x 10 x 3 BLUE COVERED (2)

30 9054

HIGH-SPEED BALL-BEARING 10 x 15 x 4 BLUE COVERED (2)

30 9314

CONE WASHER ST 6 x 12 (10)

30 9335

HEX SCREW SH M3x10 (10)

30 9343

HEX SCREW SFH M3x6 (10)

30 9452

PIN 2x10 (10)

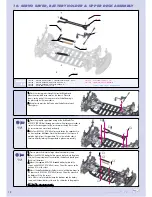

30 1110

6-CELL CHASSIS 2.5 MM GRAPHITE - CNC MACHINED

30 3015

ALU SUSP. ADJUSTABLE BULKHEAD REAR RIGHT - HARD COATED

30 3025

ALU SUSP. ADJUSTABLE BULKHEAD REAR LEFT - HARD COATED

30 5000

BALL DIFFERENTIAL WITH LABYRINTH DUST COVERS™ - SET

305000

305441

302053

302040

303025

309335

305582

305570

305431

305511

309452

305511

303015

309314

305540

301110

309035

302040

309054

302040

309343

303040

302070

302040

302070

309045

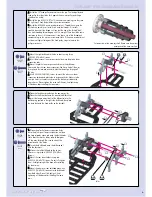

2. REAR TRANSMISSION

The new adjustable bulkheads enable you to easily adjust belt tightness.

1

1..

Press in the plastic holders for the small ball-bearings into the bulkheads as shown.

The plastic holder with the hole through it goes in the right bulkhead; the plastic holder

without the hole through it goes in the left bulkhead.

2

2..

Press #309035 (BB 5x9) ball-bearing into the plastic holder in the right bulkhead. Press

#309045 (BB 6x10) ball-bearing into the plastic holder in the left bulkhead.

3

3..

Press the large eccentric ball-bearing holders into the bulkheads. Align the tab of each

holder with the middle notch in each bulkhead as shown.

4

4..

Press #309054 (BB 10x15) ball-bearings into the eccentric covers.

Make sure the bearings turn freely and easily.

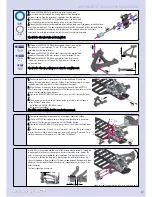

BAG

02

1

1..

Insert the layshaft with spur gear adapter through the preinstalled ball-bearing

in the bulkhead.

2

2..

Install the diff washer thrust shim.

3

3..

Install the 16T one-way pulley. Make sure that the one-way pulley "free wheels"

when rotated forward, but locks onto the layshaft when rotated backward.

4

4..

Install the fixed pulley shim.

5

5..

Press the #309452 (P 2x10) pin into the hole on the layshaft. Note that the pin

should stick out from both sides equally.

➊

➋

➋

➌

➊

➌

➍

➎

➏

➐ ➑

309054

BB 10x15

309045

BB 6x10

309035

BB 5x9

309452

P 2x10

309314

ST 6X12

How to adjust the tightness of belt:

TToo lloooosseenn rreeaarr bbeelltt::

Rotate rear nylon hubs in arrow direction ((AA))

TToo ttiigghhtteenn rreeaarr bbeelltt::

Rotate rear nylon hubs in arrow direction ((BB))

A

B

TToo rreem

moovvee hhuubb,, pprreessss

oouutt w

wiitthh ttooooll aass sshhoow

wnn..

INITIAL POSITION:

PLACE TAB

IN THIS NOTCH

➍

DETAIL

DETAIL

Summary of Contents for T1 EVO2

Page 1: ......