6

1

1..

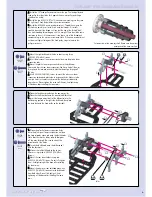

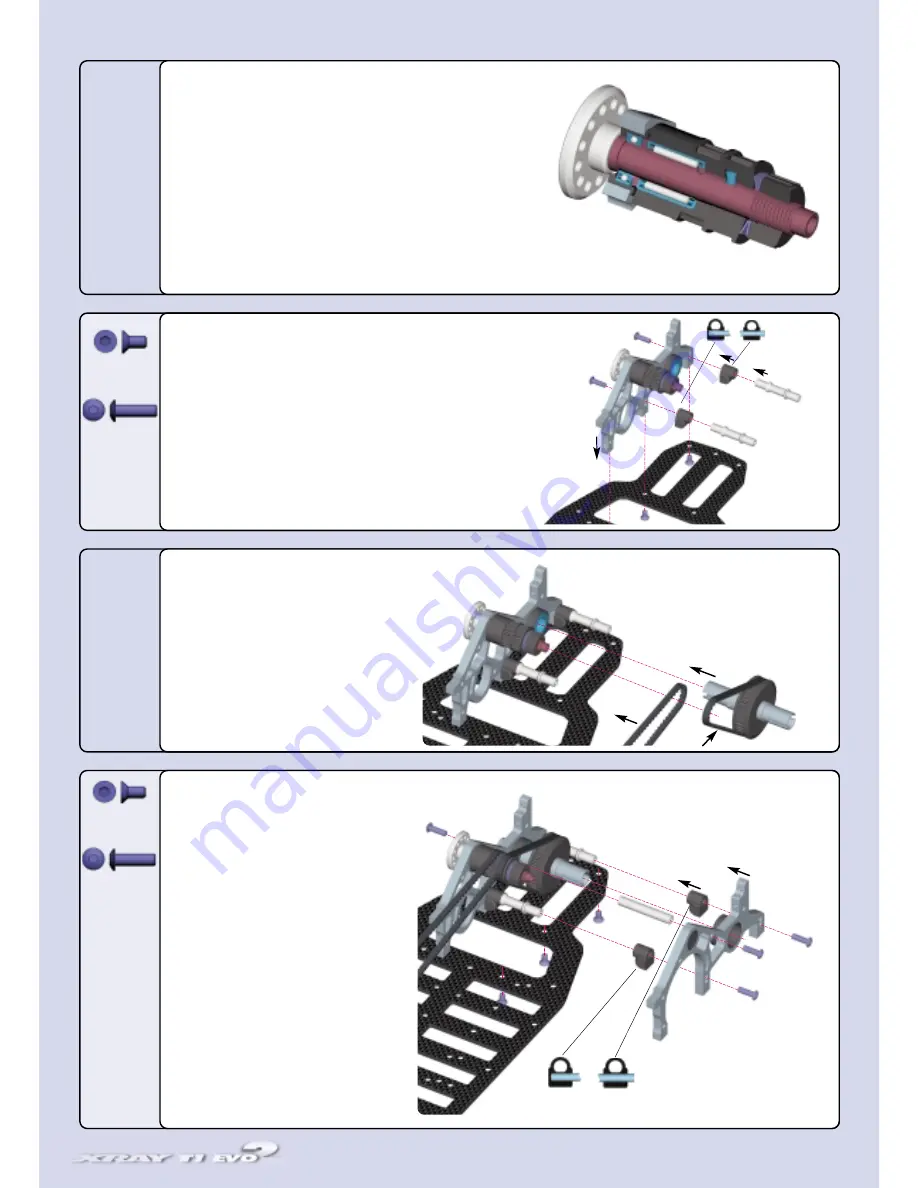

Mount the right bulkhead to the lower chassis using three

#309343 (SFH M3x6) screws.

2

2..

Insert the aluminum lower suspension holders into the plastic lower

suspension hubs.

3

3..

Mount the plastic lower suspension hubs onto the bulkheads.

Please note that the rear lower suspension hub has a hole all the way

through and the forward one has a hole that doesn't go through all

the way.

4

4..

Use #309335 (SH M3x10) screws to mount the aluminum lower

suspension holders and plastic lower suspension hubs. Make sure the

pivot pin holes in the plastic hubs are at the bottom, just above the

lower chassis. Do not tighten the screws all the way; final tightening

will be done after installing the lower arms.

1

1..

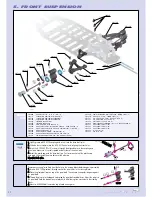

Place the long front drive belt on the one-way pulley.

2

2..

Place the short rear belt onto the assembled differential.

3

3..

Insert the longer output shaft of the differential into the

ball-bearing pressed in the right side bulkhead, then place

the drive belt onto the fixed pulley on the layshaft.

Cutaway view of the main layshaft. Please note the correct

orientation of the cone washers.

REAR TRANSMISSION

6

6..

Install the 16T fixed pulley and seat if over the pin. The fixed pulley and

fixed pulley shim should be flush against the one-way pulley and the pin

should not be visible.

7

7..

Install the two #309314 (ST 6x12) cone washers, making sure they face

the right way. Check the detail for the correct orientation.

8

8..

Install the #30 5540 one-way adjustment nut. Thread the nut onto the

layshaft very carefully so it installs true onto the threads. If it installs

crooked, back it off the thread until you feel the end of the thread "click",

then start threading forward again until it is straight. There should be some

resistance to the nut; if the movement is too loose, use a little threadlock

compound to give the nut some resistance. Note: If the one-way adjustment

nut does not tighten flat against the fixed pulley, irregular wear to the

pulleys may occur.

1

1..

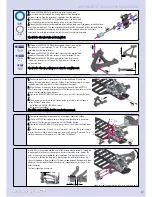

Place the plastic lower suspension hubs

onto the aluminum lower suspension holders

that are already mounted onto the bulkheads.

Note that the rear hub has a hole that goes

all the way through. Be sure to check the

orientation of the holes.

2

2..

Insert the bulkhead onto the differential

and the layshaft.

3

3..

Mount the left bulkhead to the lower

chassis using three #309343 (SFH M3x6)

screws.

4

4..

Mount the rear lower holders using two

#309335 (SH M3x10) screws. Do not fully tighten

them; final tightening will be done after installing

the lower arms.

5

5..

Mount the aluminum rear bulkhead brace with

#309335 (SH M3x10) screws onto the bulkheads

from both sides. Do not fully tighten it; final

tightening will be done after installing the lower

arms.

➋

➊

➌

➋

➊

➌

➍

➊

➋

➌

➍

➎

➎

➎

309343

SFH M3x6

309335

SH M3x10

309343

SFH M3x6

309335

SH M3x10

DETAIL

DETAIL

Summary of Contents for T1 EVO2

Page 1: ......