goes all the way through the diff.

••

To ttiigghhtteenn the front diff, rotate the

front right wheel ffoorrw

waarrdd ((+

+)).

••

To lloooosseenn the front diff, rotate the

front right wheel bbaacckkw

waarrdd ((--)).

Tighten or loosen the diff in 1/8 turn

increments, checking the diff

tightness with each adjustment.

Initial Setting:

Diff action is is smooth, but tight

enough so that it takes high effort to

rotate the front right wheel when the

front left wheel and spur gear are

held tight.

A

Ad

djju

ussttiin

ng

g tth

he

e R

Re

ea

arr D

Diiffffe

erre

en

nttiia

all ((iin

n cca

arr))

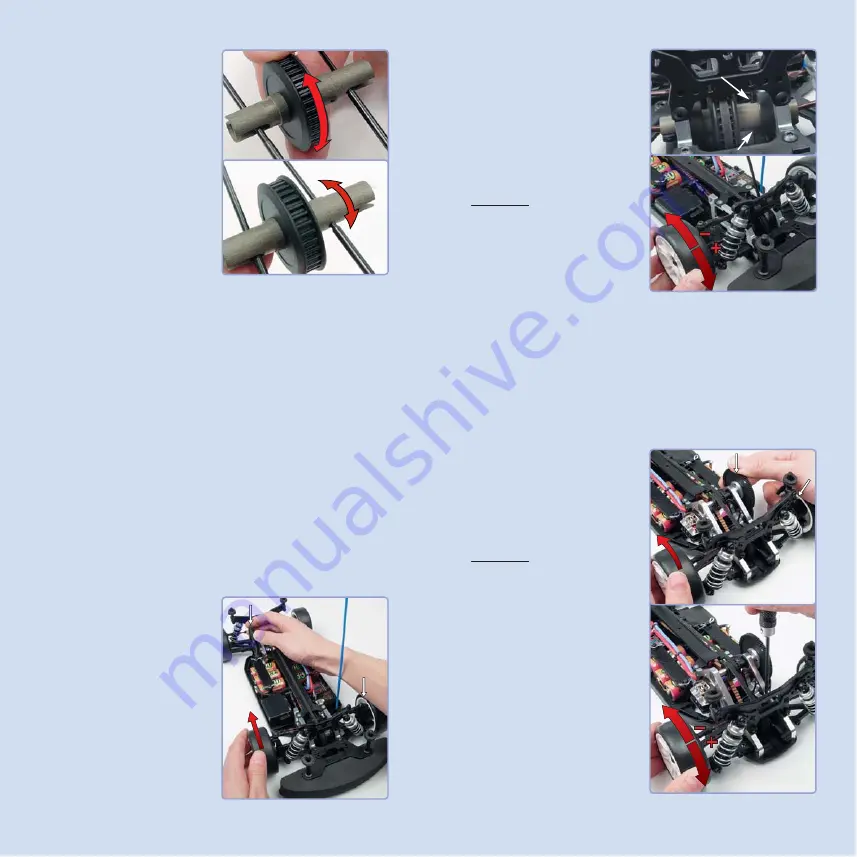

Place the car on the table with the rear end pointing towards you. To check

rear diff tightness, hold the rear right wheel and the spur gear with your

right hand, and try to rotate the rear left wheel bbaacckkw

waarrdd with your left

hand. If the rear left wheel rotates too easily, you need to tighten the rear

differential.

The diff output shaft on the right side has a hole in it. Place a small hex

wrench into the hole. Rotate the rear left wheel until the wrench goes all the

way through the diff.

••

To ttiigghhtteenn the rear diff, rotate the

rear left wheel bbaacckkw

waarrdd ((+

+)).

••

To lloooosseenn the rear diff, rotate the

rear left wheel ffoorrw

waarrdd ((--)).

Tighten or loosen the diff in 1/8 turn

increments, checking the diff

tightness with each adjustment.

Initial Setting:

Diff action is smooth, but tight

enough so that it takes high effort to

rotate the rear left wheel when the

rear right wheel and the spur gear

are held tight.

Run the car for approximately one

minute, then recheck the diffs

following the steps above.

Hint: The chassis is designed so that

you can very easily adjust the

tightness of the differentials without

disassembling the car. Simply

remove the body, lock up the diff by

inserting a thin Allen wrench through

the aligned holes, and adjust the diff.

C

Chheecckkiinngg tthhee D

Diiffffeerreennttiiaall SSlliippppaaggee

Slide two wrenches into the slots on

both sides of the diff shafts. Hold

both wrenches in one hand and try

to turn the pulley; it should take

some force to get the pulley to slip

between the two outdrives.

C

Chheecckkiinngg tthhee D

Diiffffeerreennttiiaall A

Accttiioonn

Remove the wrenches from the diff

outdrive slots. Hold the pulley

stationary in one hand, and rotate

one of the diff shafts. The other

output shaft should rotate, and the

diff action should feel smooth.

TTiigghhtteenniinngg tthhee D

Diiffffeerreennttiiaall

((oouutt ooff ccaarr))

Insert a small Allen wrench into the aligned holes in the setscrew and long

diff shaft. Turn the long diff shaft 1/16 to 1/8 of a turn clockwise (CW) to

tighten. Remove the Allen wrench and recheck the diff.

LLoooosseenniinngg tthhee D

Diiffffeerreennttiiaall ((oouutt ooff ccaarr))

Insert a small Allen wrench into the aligned holes in the setscrew and long

diff shaft. Turn the long diff shaft 1/16 to 1/8 of a turn counter-clockwise

(CCW) to tighten. Remove the Allen wrench and recheck the diff.

B

Brre

ea

ak

kiin

ng

g IIn

n tth

he

e D

Diiffffe

erre

en

nttiia

allss

Differentials must be broken in properly to operate properly. When

breaking in the diff, the balls create a groove in the diff rings; this is

normal and essential for proper operation. If you tighten the diff fully the

first time you build it, the ball will not create a proper groove, and will

become damaged. When you put the diff in the car and complete the

assembly, run the car for a few minutes, tighten the diff a little bit, and then

recheck the diff. Repeat this process several times until you have the diff

tightened to the point you want it.

Final adjustments should ALWAYS be made with the diff in the car and on the

track.

A

Ad

djju

ussttiin

ng

g tth

he

e F

Frro

on

ntt D

Diiffffe

erre

en

nttiia

all ((iin

n cca

arr))

Place the car on the table with the

front end pointing towards you. To

check front diff tightness, hold the

spur gear with your right hand and

hold the left front wheel against the

table with your right forearm, and

try to rotate the front right wheel

bbaacckkw

waarrdd with your left hand. If the

front right wheel rotates too easily,

you need to tighten the front

differential.

The diff output shaft on the left side of

the car has a hole in it. Place a small

Allen wrench into the hole, and rotate

the front right wheel until the wrench

Final Adjustments

7

8

Final Adjustments

Summary of Contents for T1R Raycer

Page 1: ......