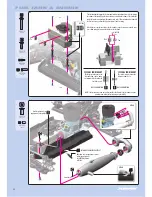

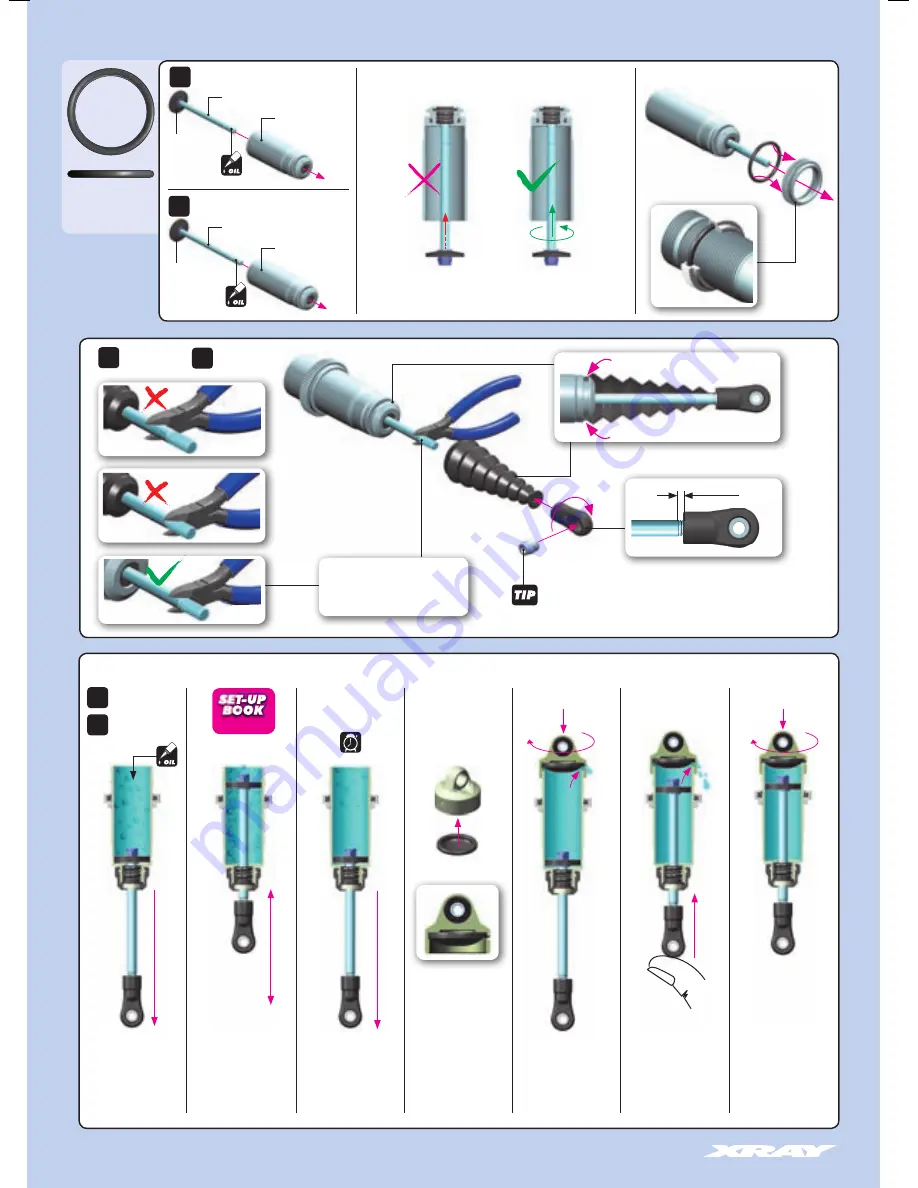

34

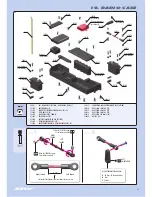

SHOCK OIL

970180

O 18x1.8

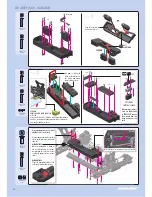

INCORRECT

INCORRECT

CORRECT

INCORRECT

CORRECT

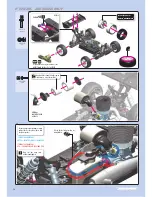

FRONT SHOCKS

REAR SHOCKS

1~1.5 mm

Gently push the shock shaft

completely into the shock

body. Excess oil will flow

through the hole in the

shock cap.

Keep the shock shaft

pushed in the shock body

and tighten the shock cap

completely.

The rebound will be at

approximately 0%.

➐

HALF TIGHTEN

TIGHTEN FULLY

100%

Follow the steps below to set the shock rebound to the default setting of 0%.

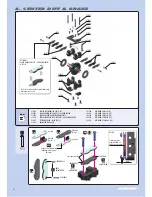

CUTAWAY VIEW

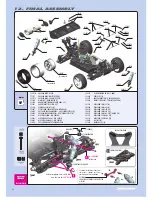

Grip the shock rod at top of exposed

threads with side cutting pliers. Be

careful not to damage the shock rod.

SHOCK ABSORBERS

DETAIL

Follow the TECH TIP on page

5 to install the pivot balls

FRONT SHOCKS

2x

REAR SHOCKS

2x

FRONT (SHORT)

Oil

500cSt

2x

REAR (LONG)

Oil

600cSt

2x

2x

1.2mm

PISTON

SHORT SHOCK BODY

SHORT SHOCK ROD

2x

1.3mm

PISTON

LONG SHOCK BODY

LONG SHOCK ROD

EXTREMELY IMPORTANT

Do not push the shock rod straight

through the lower shock body

assembly; O-ring damage may result.

Twist the shock rod through the

lower shock body assembly.

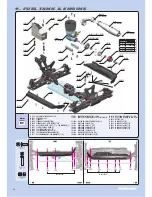

Extend the shock shaft

completely. Fill the shock

body with the shock oil. For

the FRONT shocks (short)

use 500cSt oil. For the

REAR shocks (long) use

600cSt oil.

Move the shock shaft up and

down a few times to release

the air bubbles trapped

beneath the piston.

Orient the filled shock

vertically for several

minutes with the shock

shaft fully extended. The

remaining air bubbles will

release.

Install the shock membrane

into the groove in the

upper shock cap.

Gently place the shock cap

assembly onto the filled

shock body. Excess oil will

spill from the shock. Screw

the shock cap onto the

body by only a few turns.

➊

➋

➌

➍

➎

➏

DETAIL

3~5x

UP & DOWN

50%

DEFAULT SHOCK REBOUND SETTING

0% (LOw REBOUND)

Summary of Contents for XB9

Page 1: ......