36

XT8 SET-UP

Front upper arm - inner pin Characteristics

Higher position = lower roll center

· increases on-power steering

· car is less responsive

· better on smooth, high-grip tracks with long fast corners

Lower position = higher roll center

· decreases on-power steering

· car is more responsive

· use in high-grip conditions to avoid traction rolling

· use on tracks with quick direction changes (chicanes)

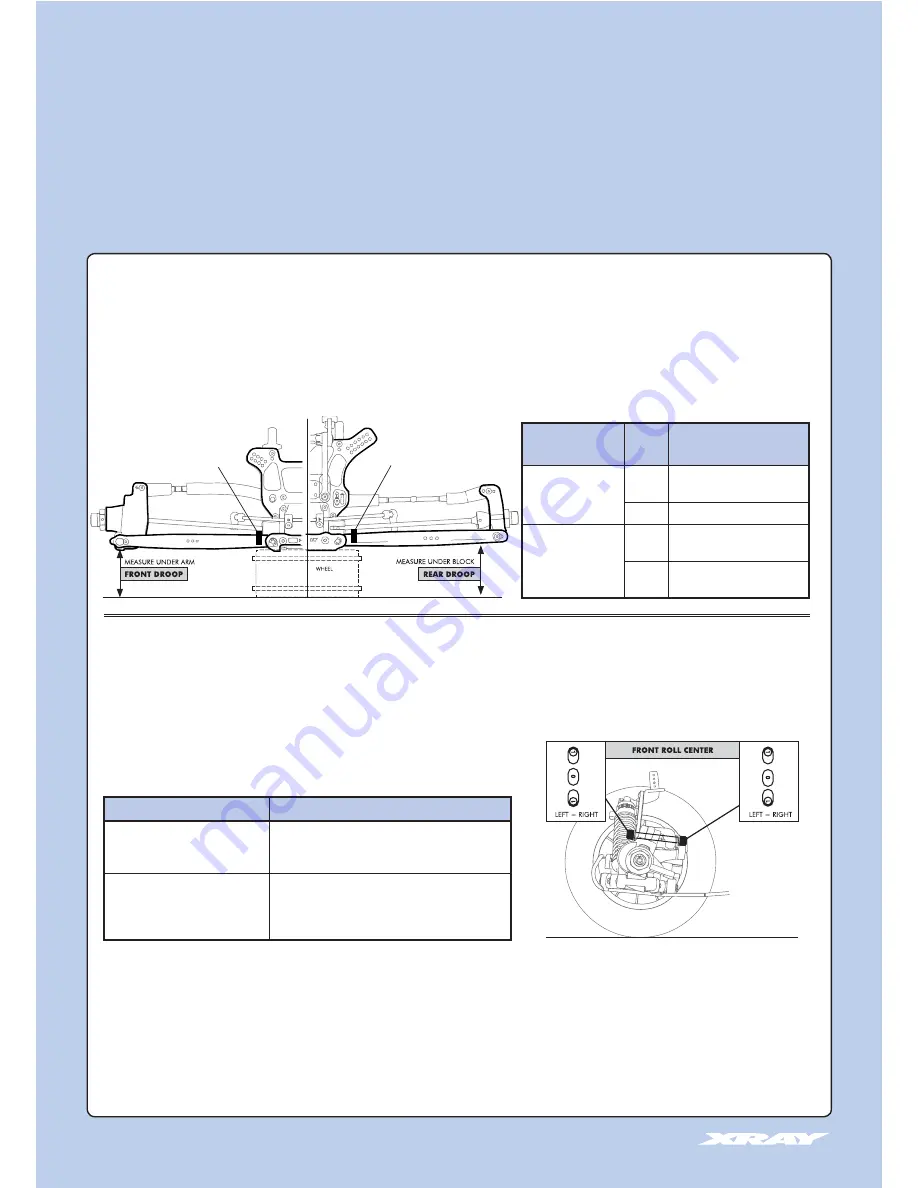

Front Roll Center

You can raise or lower the front roll center by adjusting the following components:

· Front upper arm inner pin mounting position.

Use the eccentric bushings at the front and rear of each pin to raise or lower the pin.

· Front upper camber link outer mounting position.

The outer end of the front upper camber link can be attached to the front C-hub

blocks in one of 2 positions (inner and outer).

Your XRAY XT8 luxury truggy is a top competition, precision racing machine that features multiple adjustments that allow you to set up for any track condition. The

XT8 includes innovative set-up features that allow you to change adjustments quickly and easily.

Please refer to the XT8 Basic Set-Up Sheet for a good overall starting point. After rebuilding the chassis, or in case you become lost with your set-up, always return to

the basic starting set-up described here. If you choose to experiment with set up, make small adjustments one at a time, and see if you find any improvement with each

adjustment. We strongly advise you to record and keep track of your set-up changes, record which set-ups work best at different racetracks under various conditions.

You can use the XRAY XT8 Set-Up Sheet to record your data and set-ups or visit www.teamxray.com where in the Set-up Section you can upload your own set-ups.

This set-up section describes how to adjust your XT8 to suite your driving style. For each individual set-up area, we describe the effects of changing the adjustment,

and also how to make the adjustment.

!

DROOP

Adjust front/rear droop by adjusting the front/rear down stop screws.

Tighten the screws to increase the droop height (less arm movement).

Loosen the screws to decrease the droop height (more arm movement).

Droop is a very sensitive adjustment, since it affects and alters weight transfer,

and all aspects of chassis performance are affected: braking, acceleration, jumping,

traction and rough track handling.

!

ROLL CENTER

You can adjust the front and rear roll centers of the XT8 by changing the mounting locations of various components.

Droop height

Front/

Rear

Characteristics

Less droop =

turning the screw in

Front

· less on power steering

· better for smaller jumps

Rear

· less off-power traction

More droop =

turning the screw out

Front

· more on power steering

· better handling on rough tracks

Rear

· more rear traction

· better handling on rough tracks

IMPORTANT!

Make equal adjustments on both left and right sides of the car.

TIP:

Set the car to full travel as a starting point. The front is usually

unchanged and left at full travel. For the front and rear, most drivers will

use about 2mm of adjustment range for most North American tracks.

Experiment to find the best compromise for your particular track and

driving style.

IMPORTANT!

Make equal adjustments on both left and right sides of the car, 1/2 turn

of adjustment at a time.

Set screw for droop setting

Set screw for droop setting

Summary of Contents for XT8

Page 1: ......