15

Need help or have any questions? Call us at 1-714-963-0329 or send us an Email at service@globalhobby.net

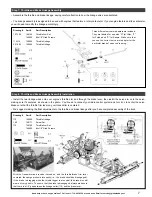

Changing the shock oil (the oil inside the shocks) will change the dampening characteristics of the shocks. Typically, if you are running

on smooth surfaces, use a heavier weight oil. If you are running on rough surfaces, use a lighter weight oil.

✦

✦

✦

✦

✦

IMPORTANT

✦

✦

✦

✦

✦

We recommend using only 100% Silicone Shock Oil. Do not use motor oil. The shock oil in the X-Cellerator Racer's

shocks is good for most off-road applications.

Moving the upper mounting position of the rear shocks to a hole in the shock tower that results in the shock assembly being more upright

will result in more "bite" in the rear of the vehicle.

Step 4: Adjusting Shock Dampening & Shock Body Mounting Location

Step 5: Adjusting the Slipper Clutch

The slipper clutch is a traction control device that uses two metal plates and two fiber pads to control how much power is transmitted from

the engine to the gear box and drive-train. Adjusting the slipper clutch allows you to fine tune how your vehicle reacts when giving it

throttle. Driving the vehicle with the slipper clutch too tight will usually result in the vehicle doing wheelies or spinning out of control

instead of accelerating. Driving the vehicle with the slipper clutch too loose will result in very poor or no acceleration at all.

●

To adjust the slipper clutch you simply turn the hex nut either in to tighten the clutch (less slip) or out to loosen the clutch (more slip).

After making each adjustment, accelerate the vehicle for a short distance while carefully watching the slipper clutch. Ideally the clutch

should slip for about the first foot after acceleration.

RECOMMENDED INITIAL SETTINGS:

●

Tighten the hex nut completely and back it off 5 turns.

✦

✦

✦

✦

✦

IMPORTANT

✦

✦

✦

✦

✦

Running the slipper clutch too loose can cause the fiber pads to wear out

very quickly and replacement under this circumstance will not be covered under warranty.

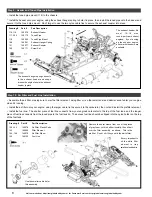

Step 7: Adjusting the Ball Differential

The ball differential should be adjusted after the first couple of runs. After that, it should require very little adjustment - only to fine-tune

the differential to your driving style or track.

●

To adjust the differential you will need to pull the passenger's side axle from the drive

cup. To do this, first remove the wheel from the axle, then remove the shock assembly

from only the shock tower. Second, lower the suspension arm down as far as possible

and the axle should come out of the drive cup.

●

After the axle is removed from the drive cup, use a small screwdriver to pop out the

nylon plate that is inside the drive cup.

●

While holding the opposite wheel with one hand, use a 5/64" (2mm) hex wrench to

tighten or loosen the hex screw in the center of the drive cup, until you're satisfied with the

operation of the differential.

●

After adjusting the differential, reinstall the assemblies in the reverse order of removal.

With the transmitter and receiver turned on, and the throttle/brake trim lever centered, the truck should roll smoothly (i.e., the brake

should be disengaged). If the brake is dragging when the throttle trigger is at neutral, the brake disc will wear out very quickly. To

ensure that the brake is disengaged, always make sure that there is a 1/8" gap between the linkage collar and the brake lever.

●

To make adjustments to the brake, simply loosen the grub screw in the wheel collar next to the brake lever and reposition it, then

retighten the grub screw.

Step 6: Adjusting the Brake Linkage