6

Visit our website at http://xtm.globalhobby.com or for Customer Service at http://globalservices.globalhobby.com

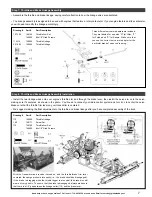

Step 5: Installing the Clutch Assembly

●

Install the flywheel, clutch shoes and clutch bell assembly onto your engine, keeping in mind that you have the choice of using a 15T,

16T or 17T clutch bell.

●

Install the engine mounts onto your engine, paying close attention to the orientation of the engine mounts, as shown in the drawing.

Drawing #

Part #

Part Description

160

149171

Screw Set

92

148334

Collet for Flywheel

94

149069

Flywheel w/Clutch Posts

182

149068

Steel Washers

95

149074

Clutch Nut

96

149066

Clutch Shoes

97

149147

Flanged Ball Bearings

99

149073

Clutch Nut Bushing & Clip

100

149067

Clutch Spring

201

149162

Split Washers

Before installing the clutch bell, lightly sand the inside surface of the

clutch bell, using 600 grit sandpaper , then clean it thoroughly, using

rubbing alcohol. Doing this will allow the clutch shoes to "bite" better,

reducing clutch slipping.

We strongly suggest applying Thread-

Lock to the engine mounting screws to

prevent them from loosening during use.

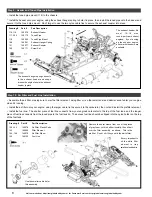

Step 6: Installing the Engine

●

Install your engine to the chassis, taking care to ensure that the engine is lined up properly and that the gear mesh between the clutch

bell and the spur gear is correct. It's important that the gears do not bind.

Tighten the clutch nut firmly,

using a pair of pliers, before

installing the bushing and

retaining clip.

Drawing #

Part #

Part Description

183

1149176

Engine Mount Screws

To set the gear mesh, place a piece of notebook paper

between the two gears. When set properly, there should be

a very slight play between the gears. If the gears are too

tight they will bind and if they are too loose they will strip out.

We strongly suggest applying Thread-

Lock to the engine mounting screws to

prevent them from loosening during use.