Page

The glow plug can make a big difference in how your engine performs. We recommend using a 'medium' or 'hot' heat-range glow plug

intended specifically for performance engines like the XTM Racing # 4 or the

XTM Racing # 3 during the break-in process. After the break-in process you

may want to use a different heat-range glow plug. Do not use glow plugs

intended for four stroke airplane engines or glow plugs with an 'idle bar'.

Using the wrong type of glow plug will cause the engine to run erratically

and make it difficult to tune properly. The wrong type of glow plug could

also damage the engine.

glOW PlUg rECOMMEnDATIOn

AIr FIlTEr

The air filter is a very important part of your engine. Failure to use the air filter

will damage the engine in a very short period of time. Make sure that you

wet the air filter element with air filter oil and use a prefilter sleeve if you are

driving in dusty or wet conditions.

See page 11 for more information.

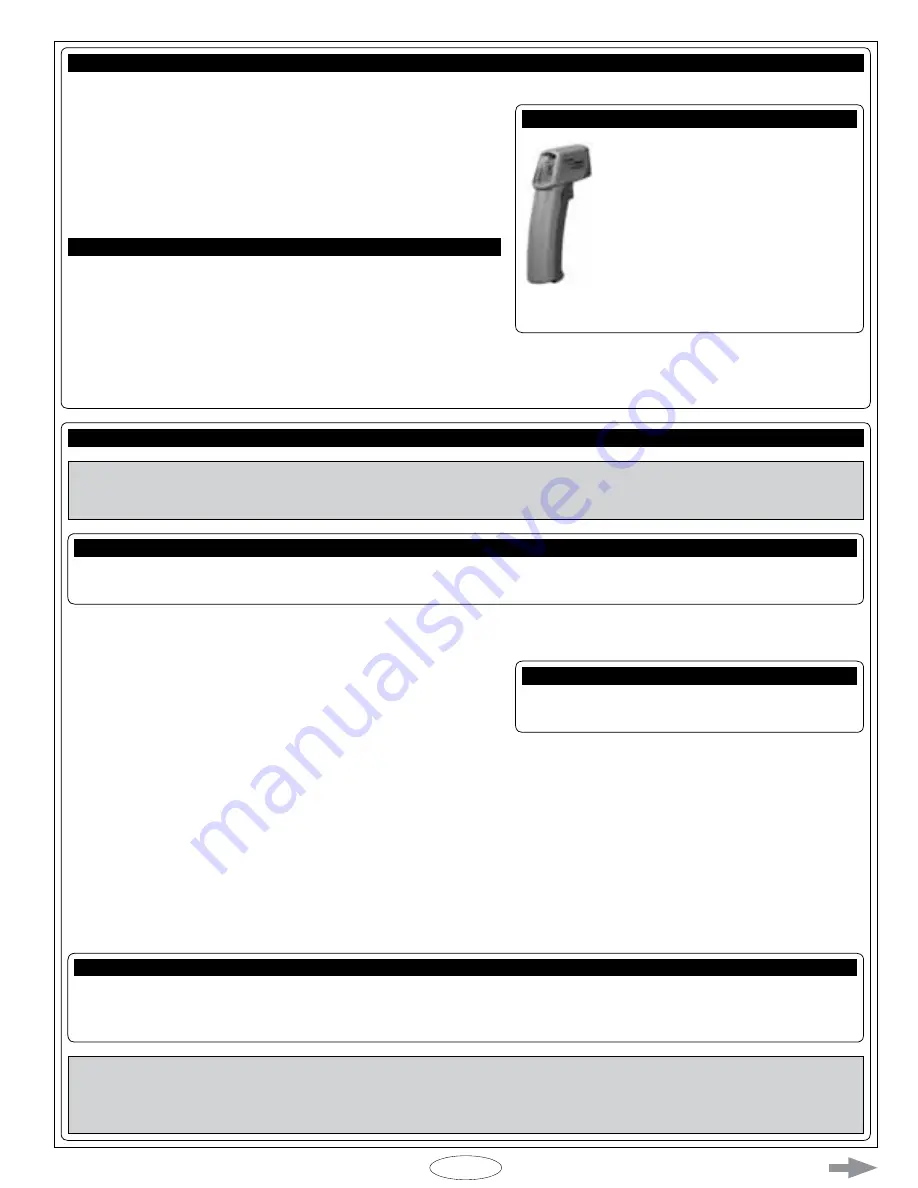

To make sure that you're not leaning out the

engine too much and overheating it during

the break-in process, we suggest using a

temperature gun to monitor the engine's

operating temperature.

During break-in, engine temperature

should not exceed 132ºC (270ºF). The

optimum engine operating temperature is

99~110ºC (210~230ºF). The minimum engine operating

temperature is 82ºC (180ºF).

EngInE BrEAK-In TIP

Under no circumstances should you operate the engine without the air filter installed on the carburettor. The air filter prevents

dust and debris from entering the engine and damaging it. If you operate your engine at any time without the air filter installed,

the engine will be quickly damaged and require replacement of the piston and sleeve (liner).

STEP 1: BrEAKIng In THE EngInE USIng THE HEAT CyClIng METHOD

WARNING:

Do not adjust the low speed needle valve until after the engine has been broken in. You can begin to adjust the low

speed needle valve after you have broken in the engine and after you have read and understood

Step 2: Fine Tuning the Engine

on the next page. The high speed needle valve is preset from the factory for easy starting in most conditions for the break-in period.

Break in the engine by running the

X

ST 4WD Truggy RTR on a flat surface (car park/parking lot, etc.) without the body shell fitted. It's

important that the engine receive adequate airflow during the break-in process, so as not to overheat.

EngInE BrEAK-In TIP

q

Follow the previous procedures to fill the fuel tank and start the engine.

q

Once the engine starts, keep the glow starter attached to the glow plug and let the engine run for about 10 seconds without giving

it throttle. This will allow the engine to warm up.

q

After the engine has been running for about 10 seconds, remove the

glow starter from the glow plug. Advance the throttle in short, quick

bursts and drive the

X

ST 4WD Truggy RTR for about 2~3 minutes. If

the engine is running rich enough, you should notice smoke coming from the tuned pipe and the engine should sound like it’s running

very rough. Also, the

X

ST 4WD Truggy RTR will barely be moving because the engine is running so rich that it won't produce much

power.

This is what you want for now.

If smoke isn't coming from the tuned pipe, richen the high speed needle valve 1/4 of a turn

(turn counterclockwise). After 2~3 minutes stop the engine by pinching the fuel line to the carburettor.

q

Let the engine cool for approximately 10 minutes, then restart it. Set the high speed needle valve mixture to a slightly leaner setting,

about 1/8 of a turn more in (turn clockwise). Repeat the procedure above, advancing the throttle in short, quick bursts and driving

the

X

ST 4WD Truggy RTR for about 2~3 minutes, then stop the engine again and let it cool for approximately 10 minutes.

q

Repeat the procedure above, leaning the high speed needle valve about 1/8 of a turn more each time (turn clockwise). In all, you should

run the engine a total of about 45 minutes. After 45 minutes of run-time the engine will be broken in. Run the engine with the high

speed needle valve set slightly rich, but lean enough to power the

X

ST 4WD Truggy RTR adequately. At this point the engine should

hold a good setting on the high speed needle valve and you can begin to fine tune the needle valve settings to increase performance.

IMPORTANT:

It is of the utmost importance that the engine never be leaned out too much. When running the engine, you should

always be able to see a slight trail of smoke coming from the tuned pipe. If you can’t, stop the engine immediately and richen the

high speed needle valve (turn counterclockwise). You should also make sure there is plenty of air flowing over the cylinder head to

keep the engine from overheating.

No two engines will have the exact same needle valve settings once broken in. Different fuels used, different types and heat-ranges of

glow plugs, the outside air temperature and air pressure all affect the engine. The factory needle valve settings on page 12 are break-in

settings. If you reset the needle valves to the factory settings, the engine will run very rich and you will need to retune the engine.

EngInE TUnIng TIP

During the break-in process, it's normal for excess fuel oil

and exhaust residue to drip from the tuned pipe.

EngInE BrEAK-In TIP