8

7FT door

8ft max

8FT door

9ft max

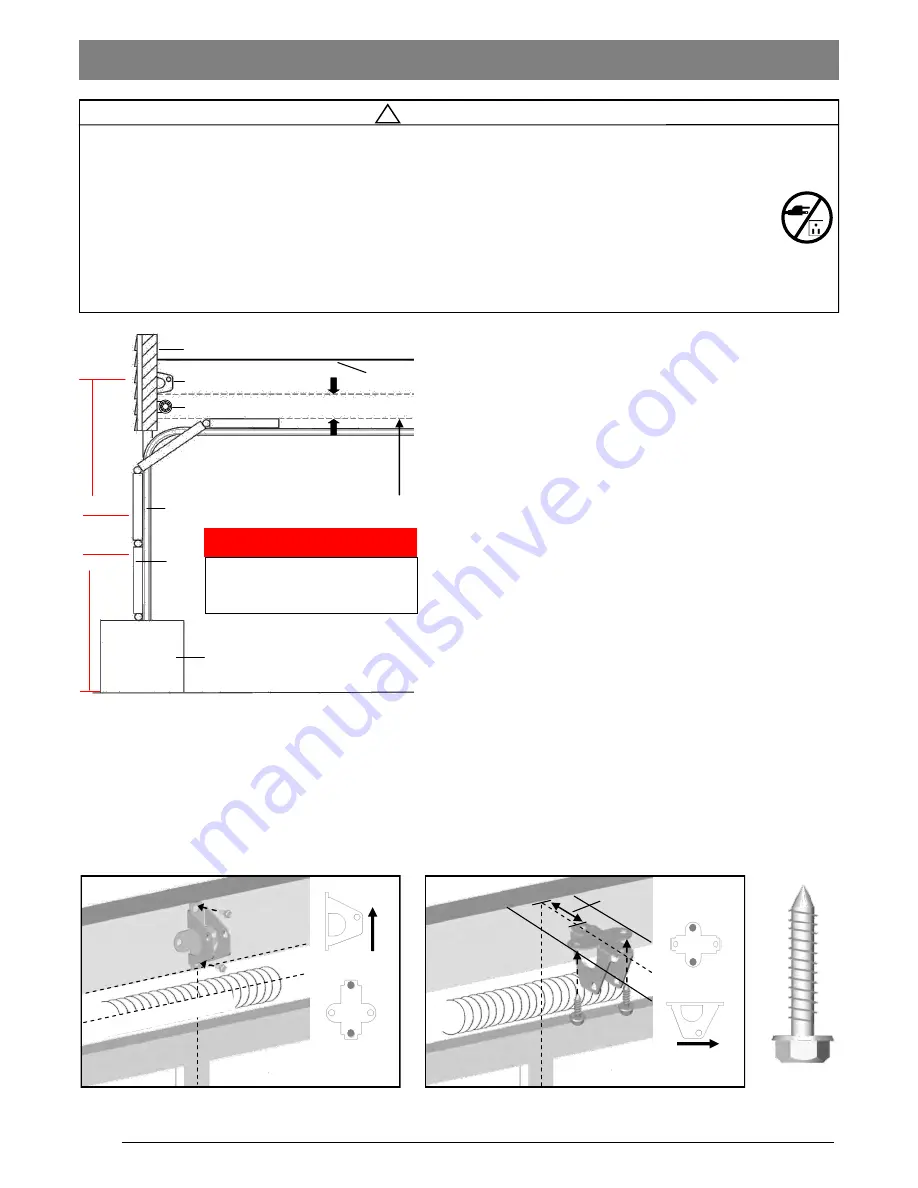

To Install Header Bracket

Note: Installation procedures may vary according to door

type.

1.

While inside your garage, close the door and mark the

vertical centerline of the garage door. Extend the line onto

the header wall above the door spring.

2.

Open the door to the highest point of travel. Mark a line on

the header wall 2“ (5cm) above the highest point of travel.

Note: DO NOT install the Header Bracket over drywall. In some

installations, it may be necessary to install a 2x4 across two wall

studs to create a suitable location for the Header Bracket.

If installing into masonry, use concrete anchors (not provided).

Wall

-

Mounting

As shown in Fig.2, place the Header Bracket on the vertical

centerline in direction shown.

Mark and drill two 3/16” holes. Fasten the Header Bracket

securely to a structural support using two 5/16” x 1

-

1/2” Lag

Screws.

Alternative Ceiling

-

Mounting

Ceiling

-

mounting is suggested ONLY when clearance is minimal.

Extend the vertical centerline onto the ceiling as shown in Fig.3.

Center the Header Bracket on the vertical mark, no more than

6” (15cm) from the header wall. Mark and drill holes to fasten the

Header Bracket securely to a structural support.

Fig.1

Ceiling

Header Bracket

Header Wall

2” (5cm) clearance

Door Track

Door

Highest Point of Door Travel

Support block on floor

Door Spring

UP

OPENER

MAX. 6” (15cm)

Highes

t Point

of Do

or Tra

vel

Vertical Centerline

Horizo

ntal Li

ne

Finis

hed

Ce

iling

Lag Screw

5/16” x 1

-

1/2”

!

WARNING

To prevent SERIOUS INJURY:

-

DO NOT connect power until instructed.

-

The Header Bracket MUST be SECURELY fastened to the structural support on the mounting wall or

ceiling, otherwise the door may not reverse when required. DO NOT install the Header Bracket over drywall.

-

Concrete anchors MUST be used when mounting the Header Bracket into masonry.

-

NEVER try to loosen, move or adjust garage door springs, cables, pulleys, brackets, or hardware, all of

which are under EXTREME tension.

-

Contact a qualified garage door service technician if your door binds, sticks or is unbalanced. An unbalanced

door might not reverse when required.

Vertical Centerline

Fig.2 (Wall

-

Mounting)

Fig.3 (Ceiling

-

Mounting)

Mounting Header Bracket

* VERY IMPORTANT! *

Max recommended rail height from floor

7ft door = 8ft max height

8ft door = 9ft max height

M

A

X

R

AI

L

H

EI

G

H

T

Floor